A production line halts. The cause: a single, unavailable capacitor. It’s a common, inexpensive part used across a dozen product lines, and it should be easy to source. Yet every distributor shows months of allocation, and the engineering team has no qualified alternate. The delay cascades through schedules, strains customer commitments, and exposes a vulnerability that was entirely preventable.

This isn’t an unavoidable supply chain disruption. It’s a structural flaw in how the Bill of Materials was designed and maintained. Most component shortages that derail production point back to preventable BOM fragilities, particularly the widespread practice of single-sourcing commodity parts. When a BOM treats every component as though only one part number will ever suffice, it builds a brittle foundation that fractures under the slightest supply pressure.

At Bester PCBA, we advocate for a fundamentally different approach. BOM health checks are not occasional audits performed in a crisis. They are a systematic practice of identifying vulnerabilities, establishing multi-source resilience through parametric qualification, and monitoring component lifecycles before allocation forces a reaction. This methodology builds BOMs that bend under supply disruption instead of breaking.

The Single-Source Trap

Single-sourcing is born from a desire for simplicity. A design team selects a capacitor, resistor, or voltage regulator that meets the spec, validates it, and locks that exact part number into the BOM. Procurement buys it. Manufacturing builds with it. The part works, so it stays. The approach feels efficient because it eliminates decisions during production, but it trades short-term convenience for long-term fragility. It creates a single point of failure.

The paradox is deepest with “jellybean” components—the resistors, capacitors, and other commodity parts that are functionally interchangeable across hundreds of manufacturers. These parts are, by definition, abundant and standardized. Yet BOMs routinely specify one manufacturer and part number for a 0.1µF ceramic capacitor as though no equivalent exists. When that specific part enters allocation or reaches its end-of-life, the production line stops. The team scrambles for the exact part or rushes a qualification process that should have happened months earlier under controlled conditions.

The consequences go beyond delays. A single-source dependency forces reactive decisions at the worst possible moment, when inventory is gone, lead times are long, and the pressure to ship is highest. Engineering must choose: accept an unqualified substitute, pay a premium for scarce inventory, or halt production to redesign. Each option carries risks that proactive multi-sourcing would have eliminated.

Our stance is unequivocal. Single-sourcing jellybean parts has no place in a resilient BOM.

Multi-Source Resilience, Not Backup Plans

The term “alternate component” often implies a backup, a secondary option for when the primary part is unavailable. This framing is insufficient. Multi-source alternates are not contingency plans; they are structural elements of a resilient BOM, designed in parallel with the primary component and qualified to the same parametric standards. The goal isn’t to have a part waiting for an emergency. It’s to have multiple, viable procurement paths at all times, eliminating the emergency entirely.

This requires a qualification process that looks past a similar description. A 10µF tantalum capacitor from one manufacturer is not automatically equivalent to one from another, even if both meet the same nominal specification. Voltage rating, temperature coefficient, equivalent series resistance (ESR), ripple current tolerance, and failure modes can all vary. An alternate that looks equivalent on a datasheet may behave differently under your circuit’s specific electrical and thermal stress, leading to field failures that trace back to a weak qualification process.

Why Not All Alternates Are Equal

The risk of superficial equivalence is highest with passive components, where the temptation to treat all parts as interchangeable is strongest. Imagine a procurement team, pressed to secure inventory, finds a capacitor with the same capacitance, voltage, and package size. Manufacturing substitutes it without telling engineering. Months later, a pattern of premature failures emerges. A root cause analysis reveals the alternate capacitor used a different dielectric with lower temperature stability, causing capacitance drift that pushed the circuit out of spec. The cost of field failures, returns, and reputation damage dwarfs any savings from the expedited purchase.

This isn’t a hypothetical. It is the predictable outcome of treating component qualification as a clerical task—matching specs on paper—rather than an engineering discipline. The lesson isn’t that alternates are risky, but that an unqualified alternate is an uncontrolled change to the design.

Parametric Guardrails Define True Equivalence

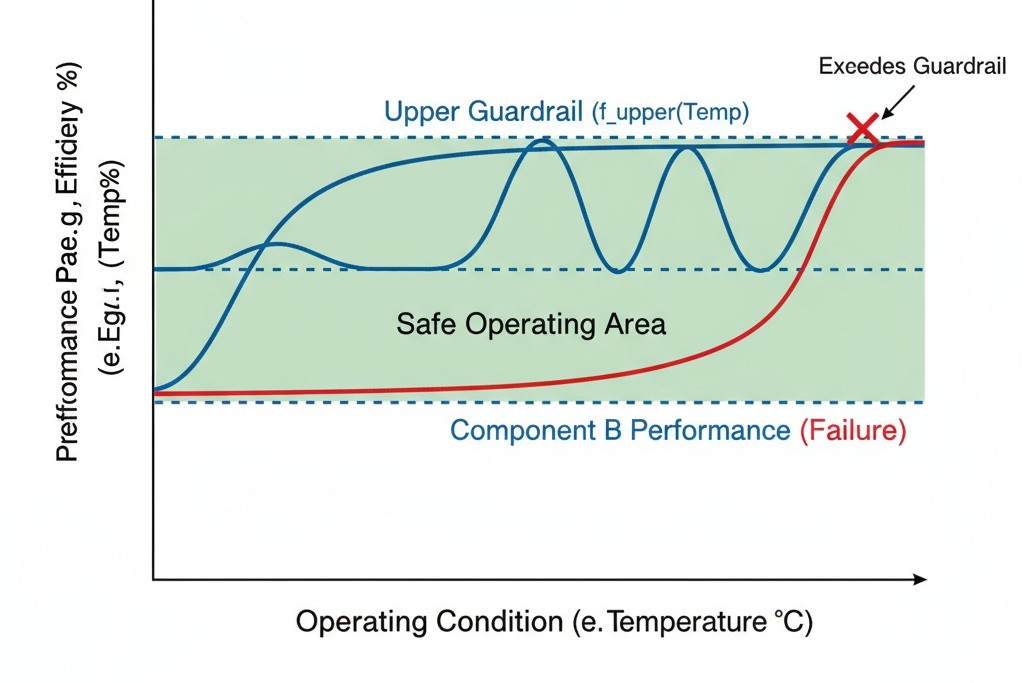

A qualified alternate is one verified to operate within defined parametric boundaries across all conditions the circuit will experience. These boundaries are the guardrails—the limits within which any component, regardless of manufacturer, will perform identically in your application. Establishing these guardrails transforms component selection from a single choice into a specification that multiple parts can satisfy. The BOM evolves from a list of specific parts to a definition of the performance envelope those parts must meet.

This means going beyond nominal datasheet values. Guardrails must account for tolerances, temperature coefficients, aging, and interactions with the surrounding circuit. A 10kΩ resistor isn’t just 10kΩ. It has a tolerance band, a temperature coefficient, and a power rating. The guardrails define how much deviation is acceptable in each parameter without affecting circuit function. Those limits become the absolute criteria for evaluating any potential alternate.

Cross-Qualification with Parametric Guardrails

Parametric qualification is the engineering process of defining and verifying these performance boundaries. It begins by identifying the critical parameters—electrical, thermal, and mechanical—and establishing the acceptable range for each. These ranges aren’t arbitrary; they are derived from the circuit’s design margins, informed by worst-case analysis, and validated through testing. A component only qualifies as an alternate if it stays within all guardrails under all operating conditions.

This is where simple form-fit-function qualification falls short. Verifying form, fit, and function confirms a part has the same physical footprint and pinout. While necessary, it’s not sufficient for electronics. Two 0805 surface-mount resistors may fit the same PCB footprint, but if one is rated for 0.125W and the other for 0.1W, they are not equivalent in a circuit dissipating 0.12W. The form and fit match, but the function does not. Parametric qualification closes this gap by verifying that the electrical and thermal behavior also aligns.

Electrical Parameter Boundaries: These guardrails define the acceptable ranges for performance-critical parameters. For a voltage regulator, this includes input voltage range, output accuracy, load regulation, and transient response. For a capacitor, it includes tolerance, voltage rating, ESR, and impedance across frequency. These parameters interact. A capacitor’s ESR affects ripple voltage on a power rail, which in turn affects a regulator’s stability. The guardrails must account for these interactions.

Thermal Performance Limits: Thermal guardrails address how a component behaves with temperature and how much heat it generates. A ceramic capacitor’s value can vary over 20% across its operating range depending on its dielectric. If the circuit relies on stable capacitance for timing, that variation is a non-starter, and the thermal coefficient becomes a critical guardrail. Likewise, a component’s thermal resistance determines how it heats the PCB, affecting its own reliability and that of nearby parts. An alternate with higher thermal resistance could create a hot spot that degrades solder joints.

Mechanical and Environmental Tolerances: These guardrails ensure the component withstands the physical stresses of the application, including vibration, shock, humidity, and thermal cycling. A tantalum capacitor fails differently under overvoltage than an aluminum electrolytic capacitor. In safety-critical applications, the failure mode itself becomes a guardrail; an alternate must not introduce new failure mechanisms. Environmental ratings are crucial in harsh conditions, where moisture or corrosive atmospheres can accelerate degradation.

Documenting these guardrails in the BOM transforms it from a parts list into an engineering specification. Instead of one part number, the BOM entry specifies the required parameters and their acceptable ranges, along with a list of pre-verified manufacturer part numbers. This gives procurement clear criteria for sourcing while ensuring engineering maintains design intent.

For teams inheriting BOMs with entrenched single-sourcing, this process can be done in reverse. Work backward from the current component to define the critical parameters that made it acceptable. Analyze the circuit to determine which of those parameters truly affect performance and define tolerances based on existing design margins. While more constrained than designing with guardrails from the start, it still enables the qualification of alternates without a full redesign.

Proactive Last Time Buy Monitoring

A Last Time Buy (LTB) notice is a manufacturer’s announcement that a component will be discontinued, usually with a six- to twelve-month window for final orders. An LTB notice is never a surprise. It is the end of a product lifecycle, signaled by years of declining demand, aging process technology, or strategic shifts. By the time the notice arrives, the component has been showing warning signs that proactive monitoring would have caught.

Proactive LTB monitoring shifts the response from reactive to strategic. The LTB notice becomes a confirmation of a trend, not the start of a crisis. This requires continuously tracking not just formal announcements but also leading indicators like declining availability, rising lead times, and shifts in distributor stock. When these signals appear, the BOM health check process flags the component, triggering the qualification of alternates or redesign planning long before the LTB notice forces a decision under pressure.

When an LTB notice does arrive, the decision matrix depends on the product’s lifecycle, the component’s role, and whether qualified alternates exist. If the BOM already includes a verified alternate, the decision is simple: shift procurement and confirm supply. If not, the team must choose between locking in LTB inventory, accelerating alternate qualification, or redesigning the circuit.

- Locking in LTB inventory makes sense if the product is also near its end-of-life or if a replacement would require recertification. The risk is a forecasting error. Overestimate demand, and you’ve locked capital in obsolete inventory. Underestimate, and you can’t fulfill orders once the stock is gone.

- Switching to a qualified alternate is the preferred path. This is where proactive health checks pay off. A component flagged as “at-risk” months earlier allows time for rigorous qualification and a controlled transition on your schedule, not the manufacturer’s.

- Redesigning the circuit is the most intensive option but may be necessary if no alternate exists and the product’s lifecycle justifies the investment. This scenario reveals the true cost of failing to design for resilience. A critical, single-source component—a specialized sensor, a proprietary IC—can hold a product hostage. Proactive monitoring provides the lead time to make redesign decisions strategically, but it cannot eliminate the work itself.

Establishing a BOM Health Check Rhythm

BOM health checks must be a rhythm, not a reaction. A quarterly review is a good baseline for most products, offering regular visibility into component risk without overwhelming engineering. This review scans each component’s lifecycle status, availability trends, and whether existing alternates remain viable. It is a diagnostic check to identify parts that have moved into a higher risk category.

For high-volume or safety-critical products, continuous monitoring is better. Automated tools can track real-time changes in availability, stock levels, and manufacturer announcements, triggering alerts when thresholds are crossed. This shifts the health check from a scheduled review to an event-driven practice, focusing attention only where it’s needed.

Certain events should trigger an immediate health check, regardless of cadence:

- New product introduction or major design revision

- A component allocation notice from a distributor

- A supplier EOL or LTB announcement

- A significant increase in lead times for a critical part

- Discovery of a new single-source component in an existing BOM

- A merger or acquisition affecting a key supplier

Integrating health checks with design release and procurement cycles ensures resilience is considered before commitments are made. A check during design review, before prototypes are built, allows changes when the cost is lowest. A check before placing large inventory orders prevents locking in supply risk. The goal is to make BOM resilience a core design criterion, evaluated with the same rigor as performance or cost.

This rhythm builds organizational muscle. The first health check on a legacy BOM will likely uncover dozens of single-source vulnerabilities. The second, a quarter later, will address a smaller set of new risks. Over time, the practice shifts from firefighting to maintenance. The BOM evolves from a fragile artifact into a resilient specification that outlasts inevitable shortages.