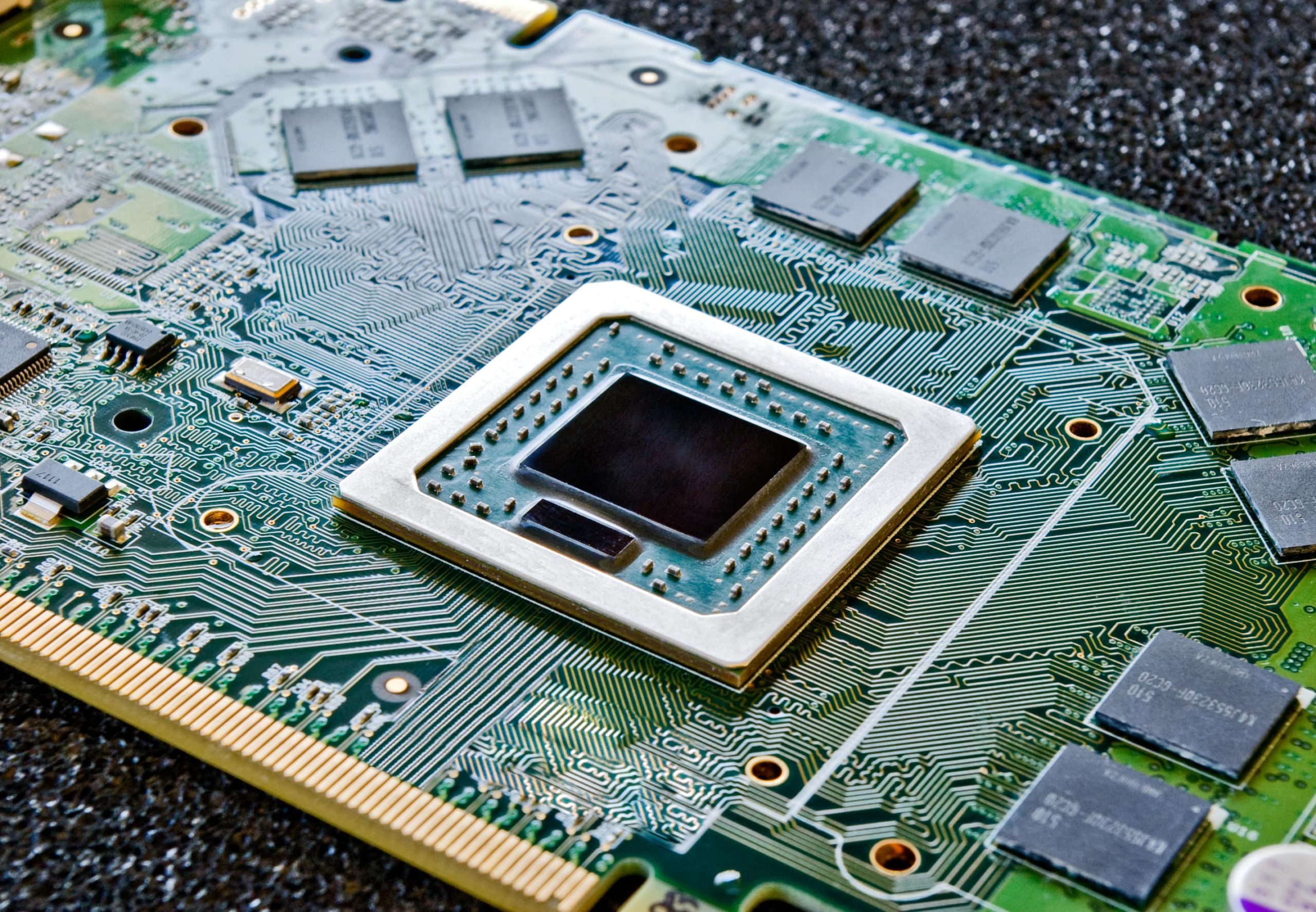

HDI PCB

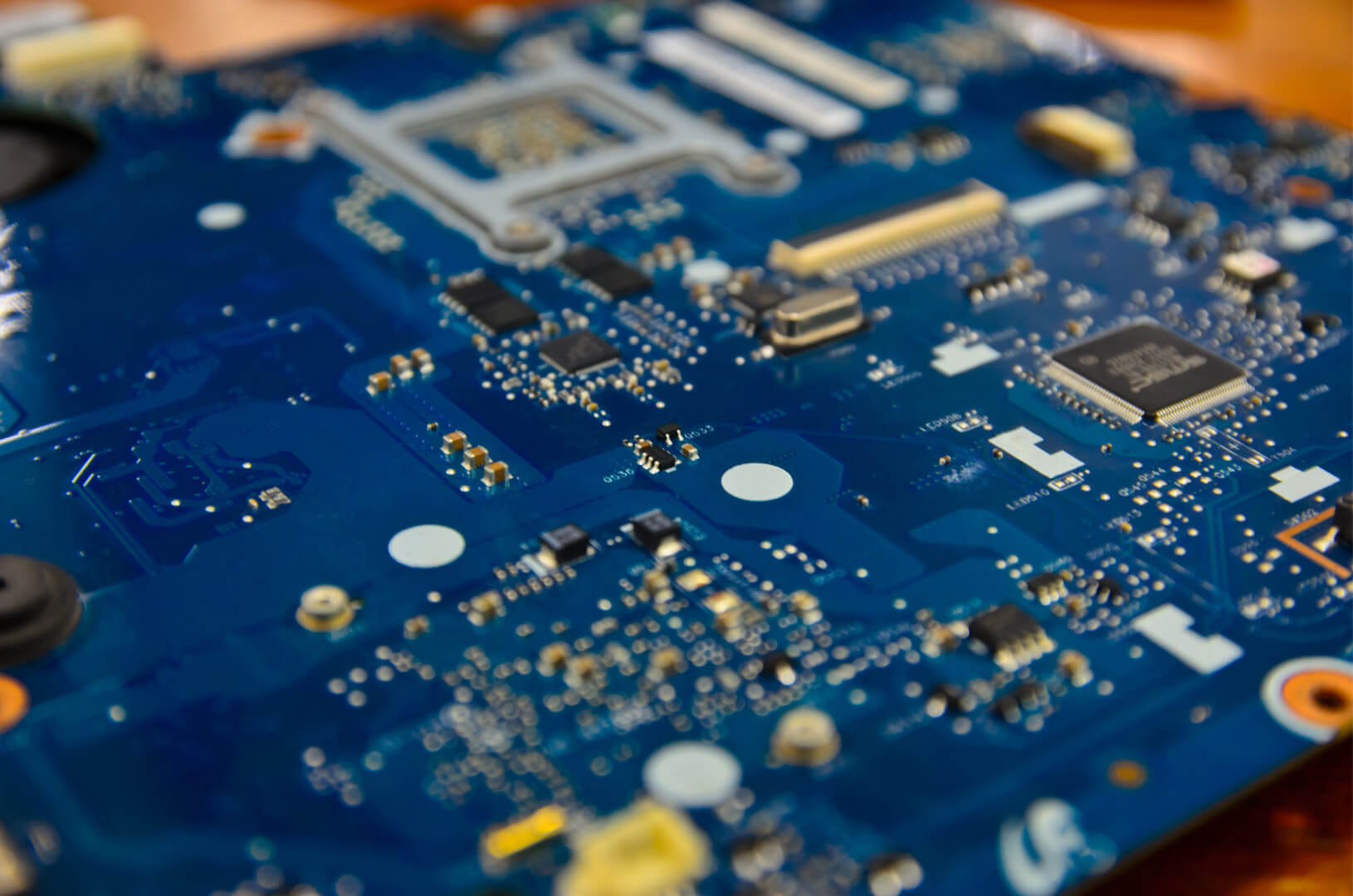

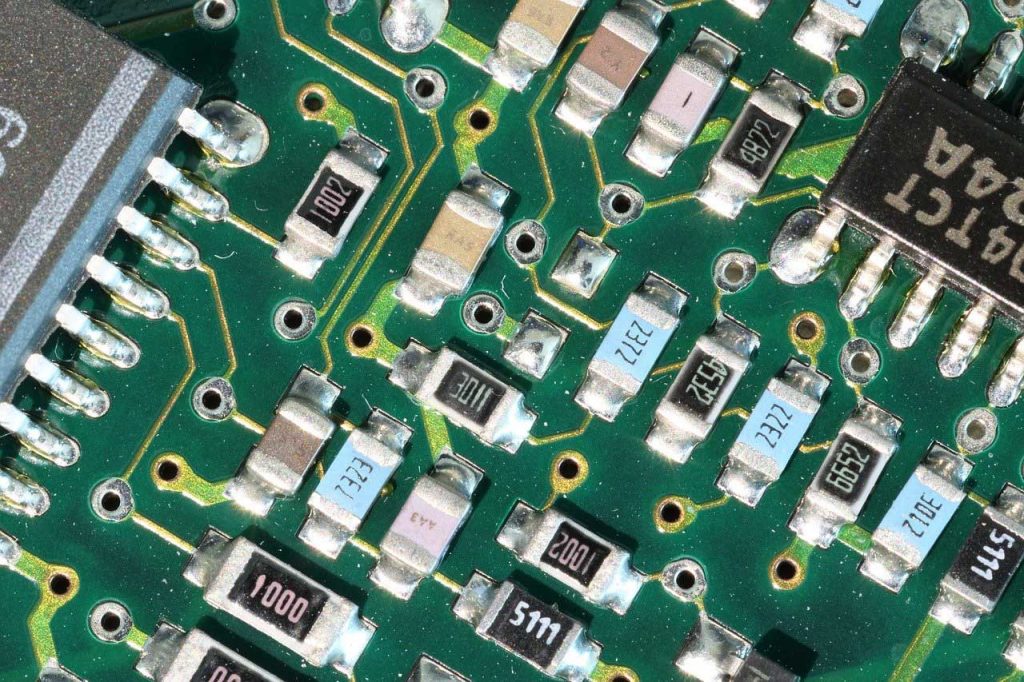

HDI(high-density interconnect) PCBs are advanced circuit boards designed with complex and intricate features that allow for high-density routing and component placement. These boards utilize microvias, fine lines, and small vias to maximize the available space on the board, resulting in reduced size, improved performance, and enhanced functionality. With our state-of-the-art manufacturing facilities and cutting-edge technology, we specialize in producing HDI PCBs that cater to a wide range of applications, including smartphones, tablets, wearables, automotive electronics, and medical devices. Our team of skilled engineers and technicians meticulously design and fabricate HDI PCBs, ensuring the highest levels of precision, reliability, and quality.

By partnering with Bester for your HDI PCB needs, you can expect superior performance, exceptional signal integrity, and improved thermal management. With our commitment to innovation and customer satisfaction, we strive to deliver HDI PCBs that exceed expectations and drive the success of your electronic products. Trust Bester for all your HDI PCB requirements and experience the difference in quality and service that sets us apart from the competition.

Why Choose Bester

Strong Assembly Capacities

With state-of-the-art facilities and a highly skilled team, we have the capacity to handle even the most complex PCB assembly projects, ensuring your products are manufactured efficiently and accurately.

Quality Assurance

Our rigorous quality control processes and extensive testing procedures guarantee that every PCB assembly we produce meets the highest industry standards for reliability and performance, giving you peace of mind and confidence in our services.

One-stop Service

From PCB fabrication and design to component sourcing and IC programming, Bester offers a comprehensive range of services under one roof, streamlining the production process and saving you time and effort.

Fast Turnaround

Our commitment to fast turnaround times means that your PCB assembly projects will be completed on schedule, allowing you to meet your production deadlines and get your products to market quickly.

Clients and Certifications

Industries We Serve

Automotive

We understand the critical role that PCBA plays in the automotive industry. With our comprehensive PCBA services, we cater to the specific needs of automotive manufacturers, helping them deliver reliable and high-performing electronic systems.

LED

In the LED market, Bester provides top-notch PCBA solutions that are essential for the production of high-quality LED lighting products. We work closely with LED manufacturers to ensure that their PCBAs meet the stringent requirements of energy efficiency, durability, and performance.

Consumer Electronics

Bester caters to the consumer electronics market by offering a wide range of PCBA services that enable the production of innovative and user-friendly electronic devices. We collaborate with consumer electronics manufacturers to ensure that their PCBAs meet the highest standards of quality and functionality.

Industrial

In the industrial sector, Bester’s PCBA services play a crucial role in the development of reliable and efficient electronic systems. We work closely with industrial equipment manufacturers to meet their specific requirements, ensuring that our PCBAs can withstand harsh environmental conditions and deliver optimal performance.

PCBA APPLICATIONS

Bike Light PCBA

PIR Motion Sensor PCBA