Why Work with Us for SMT Assembly?

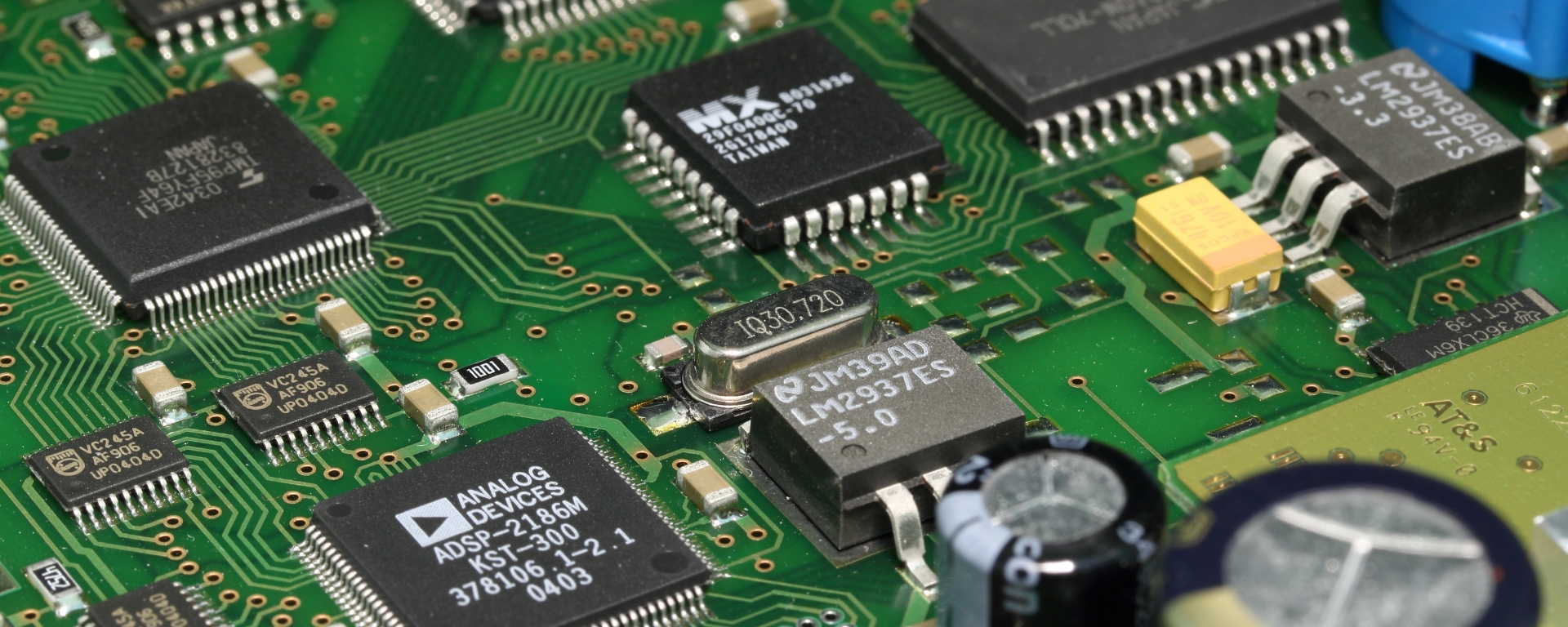

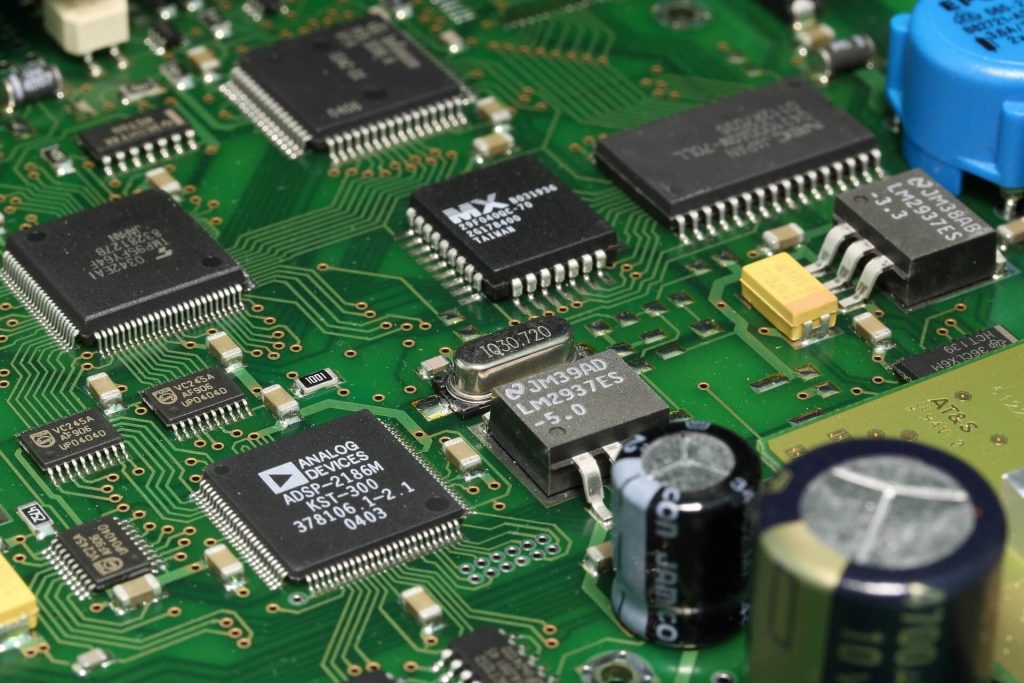

PCB Assembly

Bester Tech offers one-stop, full and partial turnkey PCB assembly services to meet all customer’s requirements and save time. Our quality-driven PCB assembly process ensures that your finished project is of the highest quality.

In full turnkey PCBA, we handle everything, including making circuit boards, ordering components, online order tracking, quality inspection and final assembly.

In partial turnkey PCBA, customers are responsible for supplying us the certain components, a partial list of parts, and the remaining parts. You can order the PCBs and partial components. We will fix the remaining parts, and manufacturing and assembly will be handled by us.

If needed, add more content here.

At MOKO, we perform both manual and automated through hole PCB assembly according to different project requirements. Generally speaking, we do hand component insertion and hand soldering for highly complicated assembly projects and use automated through-hole PCBs techniques for small-volume production.

PCB Assembly Process

One of the most important factors in the overall efficiency of each PCB assembly project is the client’s understanding of our process. The number of steps involved in the PCB assembly process depends upon the specific nature of the project in question, as illustrated below, and each of these steps is explained briefly in the following sections.

For simplicity’s sake, some intermediary stages are not shown; for example, each stage includes individual inspection upon completion. Being familiar with this process in advance, a savvy engineer can design their PCB specifically for a fast and efficient assembly process by minimizing the overall number of steps required.

DFM Check

DFM checks our client’s PCB design and looks for issues that may influence the final product negatively, such including missing, redundant or potentially problematic features. And the consistency across different design documents like BoM and Gerbers.

IQC

Inspect all incoming materials and handle quality problems before the SMT assembly process. Bester IQC and procurement team will check for model numbers, shape, sample test, etc to ensure all parts used are of the highest quality.

Solder Paste Printing

Solder paste printing is the actual first step in PCB assembly manufacturing process that can apply solder paste to the appropriate, necessary areas on the PCB using stencil and squeegees.

SMD Components assembly

Pick and Place SMD components to the programmed location at high speed using automated Pick&Place machines after solder paste is correctly applied to bare PCBs.

Reflow Soldering

After SMD components are placed on the boards, they are sent through reflow machines to have the solder paste to reflow, attach components and create permanent solder joints.

THT Components Assembly

Pick and Place THT components to the programmed location at high speed using automated Pick&Place machines for the wave soldering process.

wave soldering

Wave soldering is a method of PCB Assembly that involves sending boards on a conveyor through a wave of molten solder that is used to attach through-hole components to the boards.

AOI & X-ray

Inspect and verify that no mistakes have been made and that all parts have been correctly placed using automated optical inspection(AOI) and X-Ray technology and machines.

Final inspection & repairing

The final inspections include visual inspection by our quality assurance team and post AOI inspection for flaws and functions. It’s also known as functional test.

QC / packaging

All assembled boards are packaged per clients’ request in anti-static packaging and be prepared for shipping under our QC team.

PCB Assembly Process

One of the most important factors in the overall efficiency of each PCB assembly project is the client’s understanding of our process. The number of steps involved in the PCB assembly process depends upon the specific nature of the project in question, as illustrated below, and each of these steps is explained briefly in the following sections.

DFM Check

DFM checks our client’s PCB design and looks for issues that may influence the final product negatively, such including missing, redundant or potentially problematic features. And the consistency across different design documents like BoM and Gerbers.

IQC

Inspect all incoming materials and handle quality problems before the SMT assembly process. Bester IQC and procurement team will check for model numbers, shape, sample test, etc to ensure all parts used are of the highest quality.

Solder Paste Printing

Solder paste printing is the actual first step in PCB assembly manufacturing process that can apply solder paste to the appropriate, necessary areas on the PCB using stencil and squeegees.

SMD Components assembly

Pick and Place SMD components to the programmed location at high speed using automated Pick&Place machines after solder paste is correctly applied to bare PCBs.

Reflow Soldering

After SMD components are placed on the boards, they are sent through reflow machines to have the solder paste to reflow, attach components and create permanent solder joints.

THT Components Assembly

Pick and Place THT components to the programmed location at high speed using automated Pick&Place machines for the wave soldering process.

wave soldering

Wave soldering is a method of PCB Assembly that involves sending boards on a conveyor through a wave of molten solder that is used to attach through-hole components to the boards.

AOI & X-ray

Inspect and verify that no mistakes have been made and that all parts have been correctly placed using automated optical inspection(AOI) and X-Ray technology and machines.

Final inspection & repairing

The final inspections include visual inspection by our quality assurance team and post AOI inspection for flaws and functions. It’s also known as functional test.

QC / packaging

All assembled boards are packaged per clients’ request in anti-static packaging and be prepared for shipping under our QC team.

Why Choose Bester

Strong Assembly Capacities

With state-of-the-art facilities and a highly skilled team, we have the capacity to handle even the most complex PCB assembly projects, ensuring your products are manufactured efficiently and accurately.

Quality Assurance

Our rigorous quality control processes and extensive testing procedures guarantee that every PCB assembly we produce meets the highest industry standards for reliability and performance, giving you peace of mind and confidence in our services.

One-stop Service

From PCB fabrication and design to component sourcing and IC programming, Bester offers a comprehensive range of services under one roof, streamlining the production process and saving you time and effort.

Fast Turnaround

Our commitment to fast turnaround times means that your PCB assembly projects will be completed on schedule, allowing you to meet your production deadlines and get your products to market quickly.

Clients and Certifications

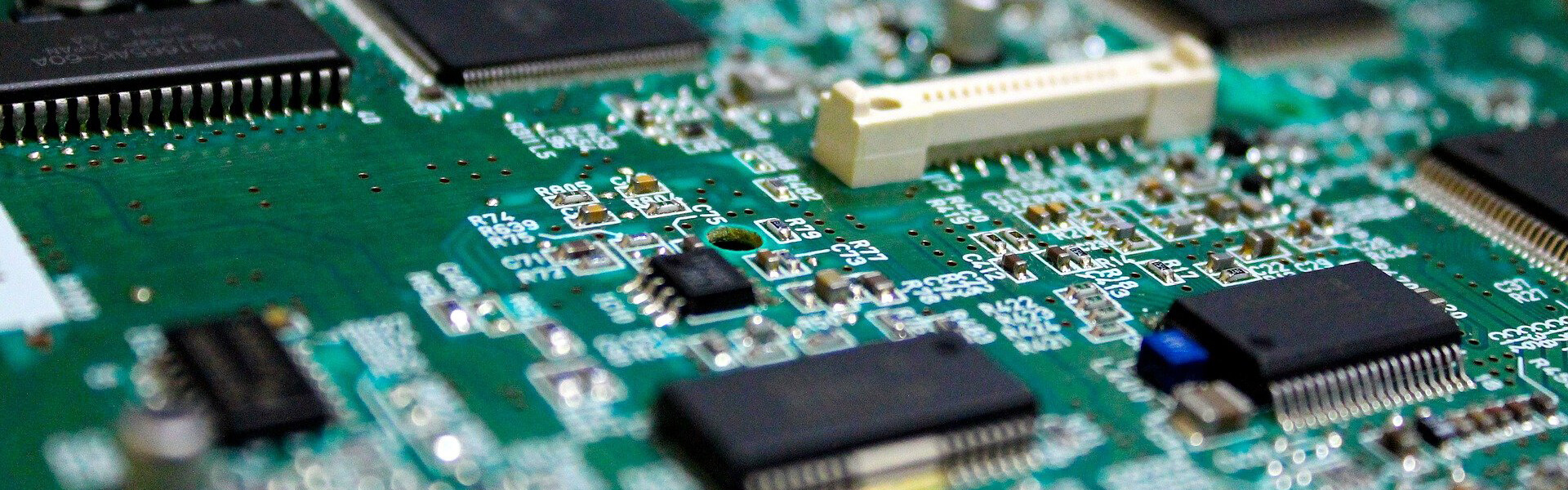

Industries We Serve

Automotive

We understand the critical role that PCBA plays in the automotive industry. With our comprehensive PCBA services, we cater to the specific needs of automotive manufacturers, helping them deliver reliable and high-performing electronic systems.

LED

In the LED market, Bester provides top-notch PCBA solutions that are essential for the production of high-quality LED lighting products. We work closely with LED manufacturers to ensure that their PCBAs meet the stringent requirements of energy efficiency, durability, and performance.

Consumer Electronics

Bester caters to the consumer electronics market by offering a wide range of PCBA services that enable the production of innovative and user-friendly electronic devices. We collaborate with consumer electronics manufacturers to ensure that their PCBAs meet the highest standards of quality and functionality.

Industrial

In the industrial sector, Bester’s PCBA services play a crucial role in the development of reliable and efficient electronic systems. We work closely with industrial equipment manufacturers to meet their specific requirements, ensuring that our PCBAs can withstand harsh environmental conditions and deliver optimal performance.

PCBA APPLICATIONS

Bike Light PCBA

PIR Motion Sensor PCBA

LED PCBA

PCB Assembly FAQs

Are you a certified PCB manufacturer?

Additive material process, also known as additive manufacturing, involves the123444412312312321on, such as a heated printhead or laser, to bind the layers together. Th an exact replica of the original 3D mg a fusing applicag a fusing applicaodel.

Are you a certified PCB manufacturer?

Additive material process, also known as additive manufacturing, involves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing application, sug a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicach as a heated printhead or laser, to bind the layers together. The end result is a 3D-printed object that is an exact replica of the original 3D model.

Are you a certified PCB manufacturer?

Additive material process, also known as additive manufacturing, involves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing application, such as a heated printhead or laser, to bind the layers together. The end result is a 3D-printed object that is an exact replica of the original 3D model.

Do you offer quick turn PCBA service?

Additive material process, also known as additive manufacturing, involves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing applicati

Do you accept small-batch orders?

Additive material process, also known as additive manufacturing, invg a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicaolves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing application, such as a heated printhead or laser, to bind the layers together. The end result is a 3D-printed object that is an exact replica of the original 3D model.