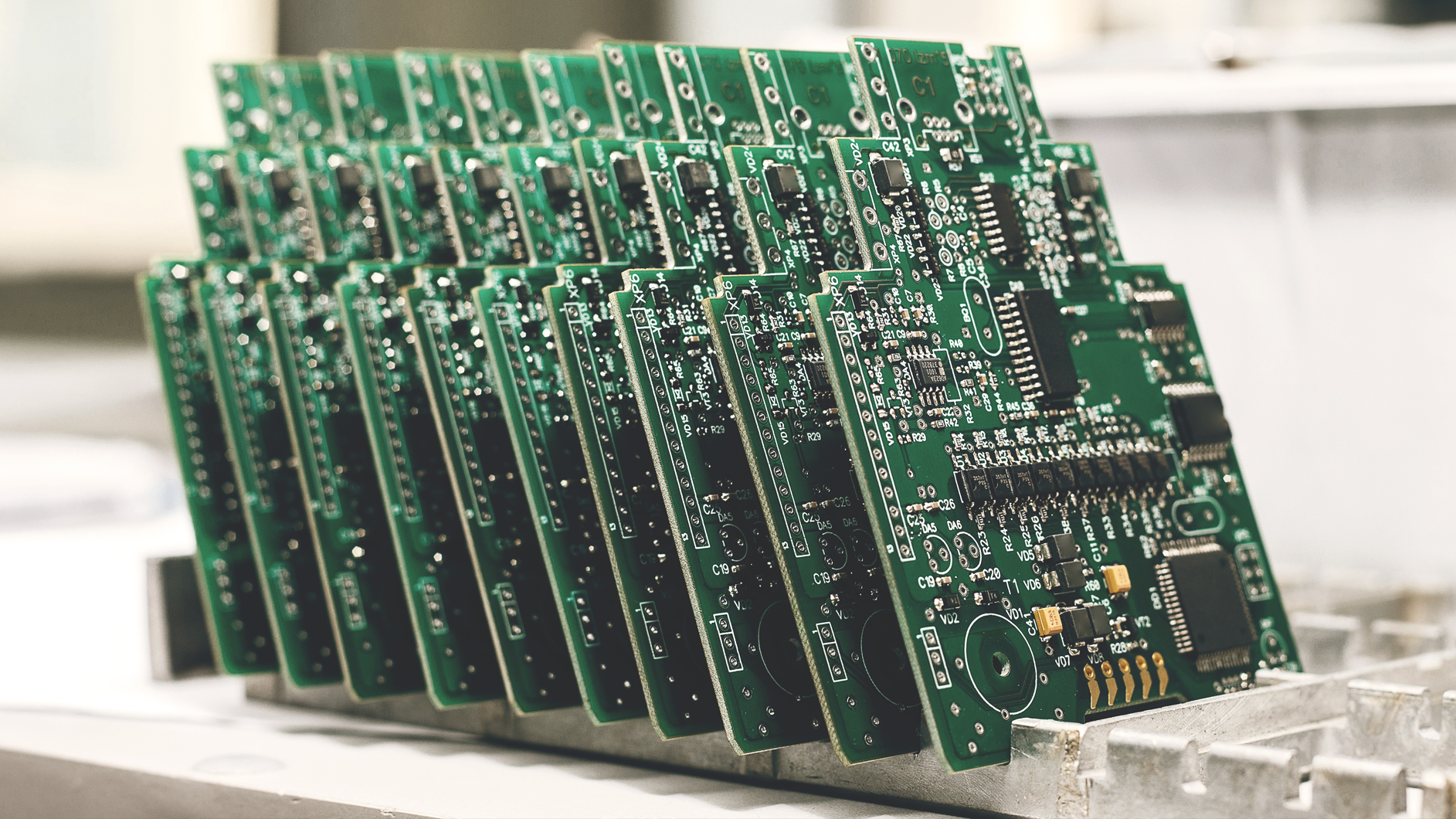

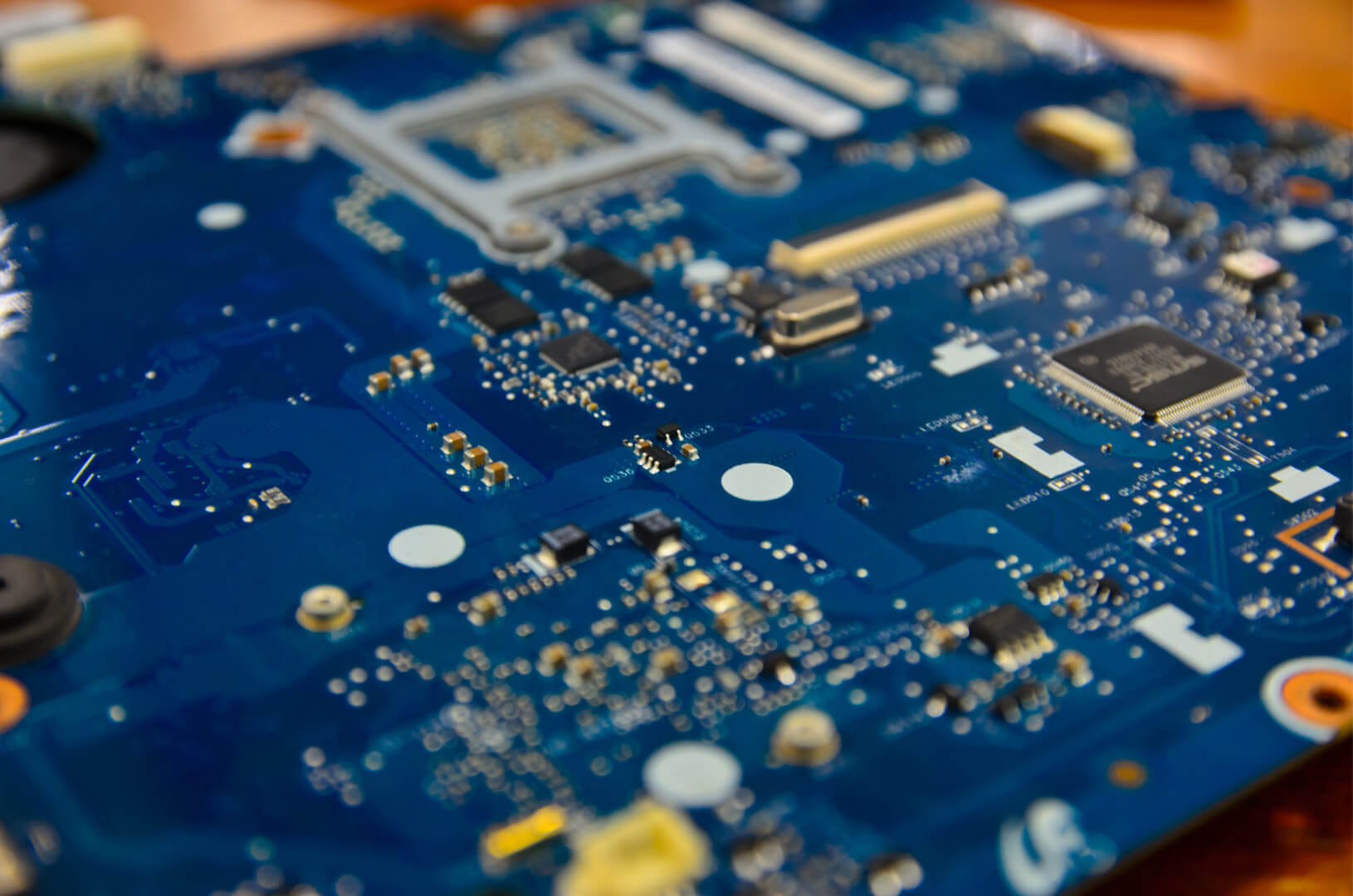

Rigid PCB

Rigid PCBs are the foundation of any electronic device, serving as a platform to connect and support various electronic components. These boards are made from a rigid substrate material, typically fiberglass-reinforced epoxy laminate, which provides exceptional strength and durability. Rigid PCBs are designed to withstand high temperatures, mechanical stress, and provide excellent electrical conductivity for optimal performance.

At Bester, we understand the significance of Rigid PCBs in the electronics industry, and that is why we ensure the highest quality standards during the fabrication process. With our state-of-the-art manufacturing facility and a team of skilled professionals, we can produce Rigid PCBs in different sizes and complexities to meet the unique requirements of our customers. Our Rigid PCBs are not only reliable but also highly customizable. We offer a range of options such as single-sided, double-sided, and multi-layered Rigid PCBs, allowing for the integration of complex circuitry in compact designs. Whether you need Rigid PCBs for consumer electronics, automotive applications, industrial equipment, or any other industry, we have the expertise and resources to deliver exceptional results.

Why Choose Bester

Strong Assembly Capacities

With state-of-the-art facilities and a highly skilled team, we have the capacity to handle even the most complex PCB assembly projects, ensuring your products are manufactured efficiently and accurately.

Quality Assurance

Our rigorous quality control processes and extensive testing procedures guarantee that every PCB assembly we produce meets the highest industry standards for reliability and performance, giving you peace of mind and confidence in our services.

One-stop Service

From PCB fabrication and design to component sourcing and IC programming, Bester offers a comprehensive range of services under one roof, streamlining the production process and saving you time and effort.

Fast Turnaround

Our commitment to fast turnaround times means that your PCB assembly projects will be completed on schedule, allowing you to meet your production deadlines and get your products to market quickly.

Clients and Certifications

Industries We Serve

Automotive

We understand the critical role that PCBA plays in the automotive industry. With our comprehensive PCBA services, we cater to the specific needs of automotive manufacturers, helping them deliver reliable and high-performing electronic systems.

LED

In the LED market, Bester provides top-notch PCBA solutions that are essential for the production of high-quality LED lighting products. We work closely with LED manufacturers to ensure that their PCBAs meet the stringent requirements of energy efficiency, durability, and performance.

Consumer Electronics

Bester caters to the consumer electronics market by offering a wide range of PCBA services that enable the production of innovative and user-friendly electronic devices. We collaborate with consumer electronics manufacturers to ensure that their PCBAs meet the highest standards of quality and functionality.

Industrial

In the industrial sector, Bester’s PCBA services play a crucial role in the development of reliable and efficient electronic systems. We work closely with industrial equipment manufacturers to meet their specific requirements, ensuring that our PCBAs can withstand harsh environmental conditions and deliver optimal performance.

PCBA APPLICATIONS

Bike Light PCBA

PIR Motion Sensor PCBA