For the teams managing procurement and inventory, the most consequential risks are rarely the most obvious. A greater threat than a delayed shipment or a pricing error often lies dormant, sealed inside the reels of seemingly perfect electronic components. It is the absorbed humidity, an invisible agent that can quietly sabotage production, scrap entire assemblies, and trigger the kinds of field failures that erode both profits and reputation.

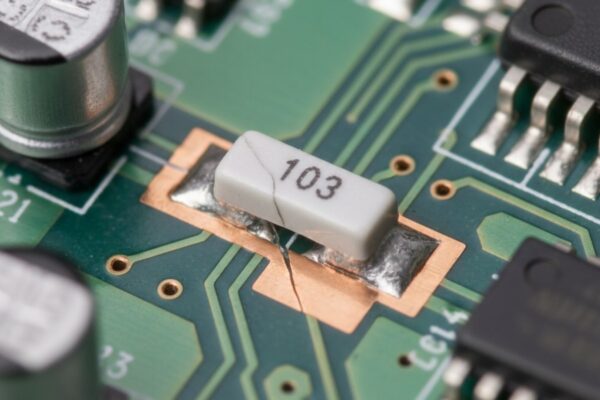

This is not a theoretical problem. It is a physical reality governed by the Moisture Sensitivity Level (MSL) standard. To treat this standard as a mere technical footnote is to fundamentally miscalculate business risk. When a component with trapped moisture meets the intense heat of solder reflow, the water vaporizes with explosive force, cracking the package from within. This failure, known as “popcorning,” transforms a component worth pennies into a liability that can nullify the value of an entire board. Understanding how to manage this phenomenon is not an engineering task; it is a critical function of inventory control and financial stewardship.

A Clock That Starts Ticking

The core of MSL management revolves around a single, unforgiving concept: floor life. This is the countdown that begins the moment a component’s protective Moisture Barrier Bag is opened. It represents the finite window of time a part can endure ambient factory conditions before it absorbs enough humidity to become a risk in the reflow oven.

This window varies dramatically. A component rated at MSL 3, a common classification, has a floor life of 168 hours. For a more sensitive MSL 5 part, that clock expires in just 48 hours. The most resilient components, rated MSL 1, have an unlimited floor life and require no special handling, but assuming a part falls into this category without confirmation is a significant gamble. The rating itself is not arbitrary; it is a critical piece of data found on the packaging’s caution label or, definitively, within the manufacturer’s datasheet. Locating and respecting this number is the first step in preventing a cascade of failures.

The consequence of letting the clock run out is often a failure mechanism called popcorning. The term itself evokes the audible crack a component can make on the assembly line, but the reality is frequently more insidious. The violent expansion of steam creates pressures that can cause delamination, where the internal layers of the component package separate. This can sever the microscopic wire bonds connecting the silicon die to the external leads.

Sometimes this results in an immediate open circuit, a defect easily caught by inspection. Far more dangerous, however, is the intermittent fault. The connection is damaged but not fully broken, creating a ticking time bomb that passes initial quality control. The final product ships, only to fail weeks or months later in the hands of a customer. A simple handling oversight in the warehouse has now escalated into a warranty claim and a crisis of brand trust.

Controlling and Resetting the Clock

Once the floor life clock has expired, the components are compromised. Using them is a direct violation of handling protocol. The only way to safely bring them back into production is to reset their internal state through a controlled heating process known as baking. This procedure uses a calibrated industrial oven to gently drive the absorbed moisture out, restoring the component to a known-dry condition.

The process requires precision. A typical baking profile might be 24 hours at 125°C, but this is not a universal rule. The component’s datasheet provides the only authoritative instructions. Some parts are sensitive to high temperatures and demand a much slower, lower-temperature bake over several days. Experience on the production floor shows that deviating from this guidance invites new problems. Too much heat for too long can cause oxidation on the component leads, a condition that severely degrades solderability and can be the source of an entirely new set of assembly defects.

Proactive control, however, is always superior to reactive recovery. The best strategy is to pause the floor life clock whenever a partial reel is not in use. The absolute minimum for this is to reseal the components in a fresh Moisture Barrier Bag with a new desiccant pack and a Humidity Indicator Card, using a vacuum sealer to remove ambient air. For a more robust solution without the expense of a fully automated system, a simple desiccator cabinet provides a stable, low-humidity environment that offers a significant upgrade in protection. These sealed cabinets, using renewable desiccant material, can reliably maintain the low humidity needed to protect high-value or highly sensitive parts.

Your First Line of Defense

Effective MSL discipline begins the moment a shipment arrives. The inspection of incoming goods must extend beyond part numbers and quantities to the integrity of the packaging itself. A punctured bag, a broken vacuum seal, or a Humidity Indicator Card showing exposure to moisture are all unambiguous signs of a compromised lot.

That small card, with its color-changing dots, is the most reliable witness to the component’s journey. A sealed bag can be deceptive, hiding a microscopic pinhole or a faulty seal. The card cannot be fooled. If its dots indicate the presence of humidity, you must trust it over the appearance of the bag. The entire lot should be quarantined from general inventory and scheduled for baking. Placing these components into stock is to knowingly accept a future failure.

This vigilance has become more critical as manufacturing processes have evolved. The industry-wide shift to lead-free solders, for instance, has raised the stakes considerably. Lead-free alloys require higher reflow temperatures, often reaching 240°C to 260°C. This additional thermal stress generates far greater steam pressure inside a component, meaning a part that might have survived a lower-temperature process is now much more likely to fail. There is simply less room for error.

Furthermore, the standard JEDEC floor life calculations assume a factory environment of 60% relative humidity or less. For facilities in high-humidity regions, this baseline is a dangerous fiction. The ambient air is a more aggressive threat, and the floor life clock accelerates. In these locations, rigorous controls like the use of nitrogen-purged dry cabinets for all opened components shift from being a best practice to an operational necessity. The environment itself demands a higher standard of discipline.