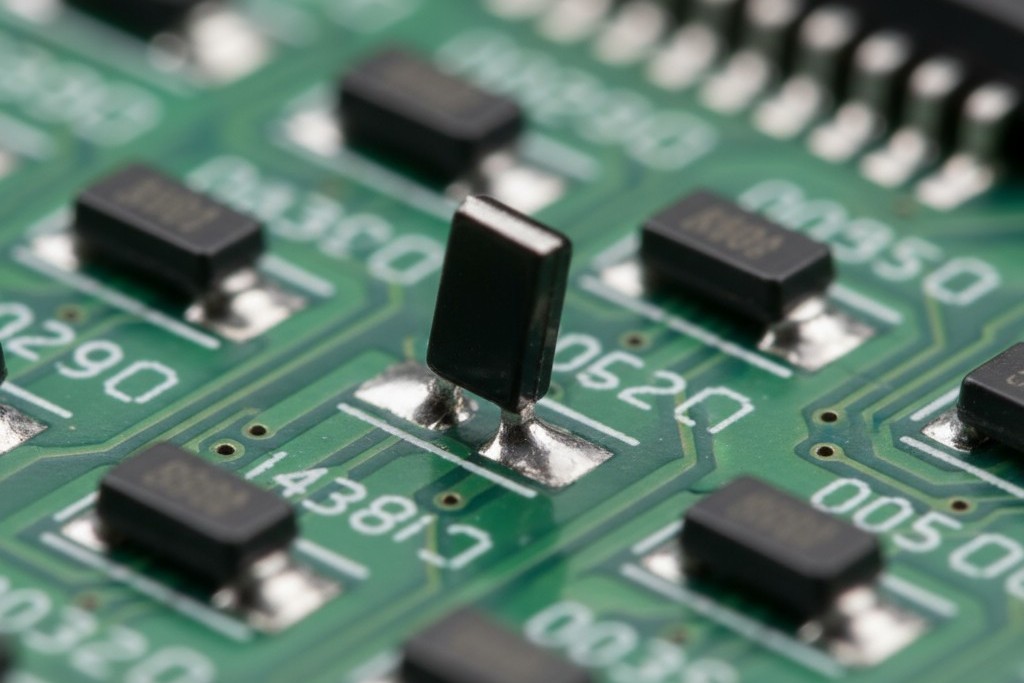

The push for PCB miniaturization has made 0402 passives the default choice in many designs. Smaller footprints promise tighter routing, higher component density, and the clean aesthetic of a compact board. For consumer electronics destined for a quiet life in controlled environments, this reflex makes sense. Size reduction can translate directly to savings in materials and real estate with few reliability trade-offs.

But that logic collapses in harsh-duty applications.

For off-road vehicles, rail systems, and industrial controls—any environment defined by sustained vibration, rapid thermal cycling, and the need for field service—the tiny 0402 passive introduces failure modes that quietly erase any initial savings. Tombstoning during assembly, solder joint fatigue under vibration, and the brutal economics of rework all argue for the slightly larger 0603 footprint. In harsh environments, the miniaturization reflex must be challenged.

How Thermal Mass Drives Tombstoning

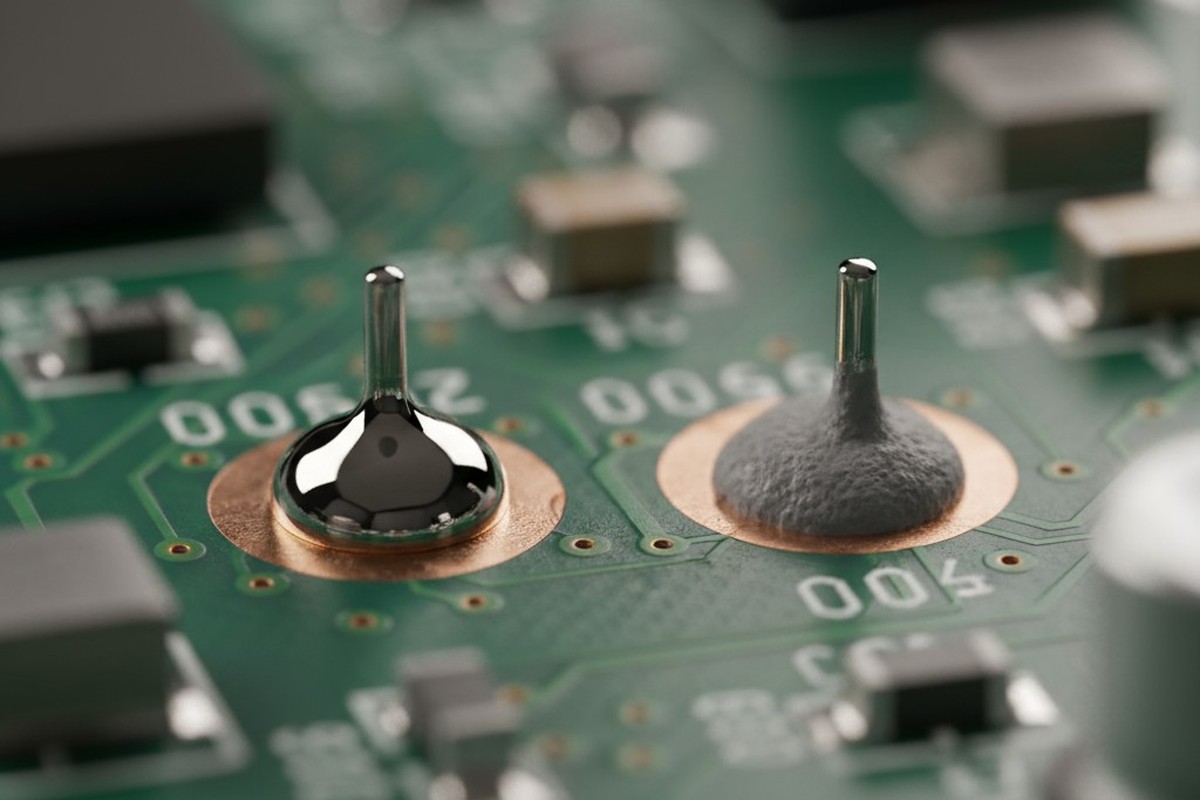

Tombstoning is exactly what it sounds like: a passive component stands vertically on one pad after reflow, useless. It’s an open circuit that can easily escape visual inspection. The root cause is a differential in heating rates during reflow, a physical process that becomes more punishing as component mass shrinks.

During reflow, solder paste on each pad liquefies, exerting surface tension on the component. Ideally, these forces balance, pulling the component flat. But if one pad heats faster, its solder liquefies first, creating an unbalanced pull. This rotational torque can flip the component upright if it’s strong enough to overcome the part’s inertia. With 0402 passives, which weigh less than a milligram, it often is.

The Mechanics of Uneven Heating

The thermal mass of the component, its pads, and the surrounding copper all interact during the reflow ramp. If one pad connects to a large copper pour or ground plane, that plane acts as a heat sink, slowing the temperature rise of the solder paste. The opposite pad, perhaps connected to a thin, thermally isolated trace, heats much faster. Solder on the hotter pad liquefies first, wetting the component and pulling with full force while the other end remains anchored in solid paste.

This thermal differential exists in all designs, but its effect depends on the component’s resistance to being rotated. A heavier 0603 component has greater inertia and resists the torque. An 0402, with its negligible mass, does not. When rapid thermal ramps are used to optimize cycle times, or when a board has unavoidable thermal asymmetries, the 0402 becomes a prime candidate for tombstoning.

Structural Vulnerability

The 0402 footprint is tiny—about one millimeter by half a millimeter. Its solder joints occupy a minuscule contact area. Even small forces generate significant rotational moments because the lever arm is short and the stabilizing mass is nearly nonexistent. An 0603 component is 50% larger, but its mass is disproportionately greater, as volume scales cubically. While not immune to differential heating, the thermal imbalance required to flip an 0603 is far higher.

Pad design and solder paste volume can mitigate the risk. Asymmetric pads or solder mask dams can help, but these add design complexity and process sensitivity. They cannot eliminate the fundamental vulnerability of low mass. For rugged products that might see multiple reflow cycles during rework or are assembled in less-than-perfect conditions, that margin for error is critical. The 0603 provides it through sheer physics.

Vibration-Induced Solder Joint Failure

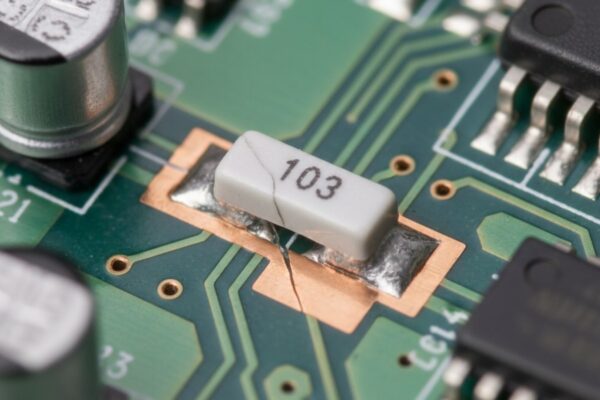

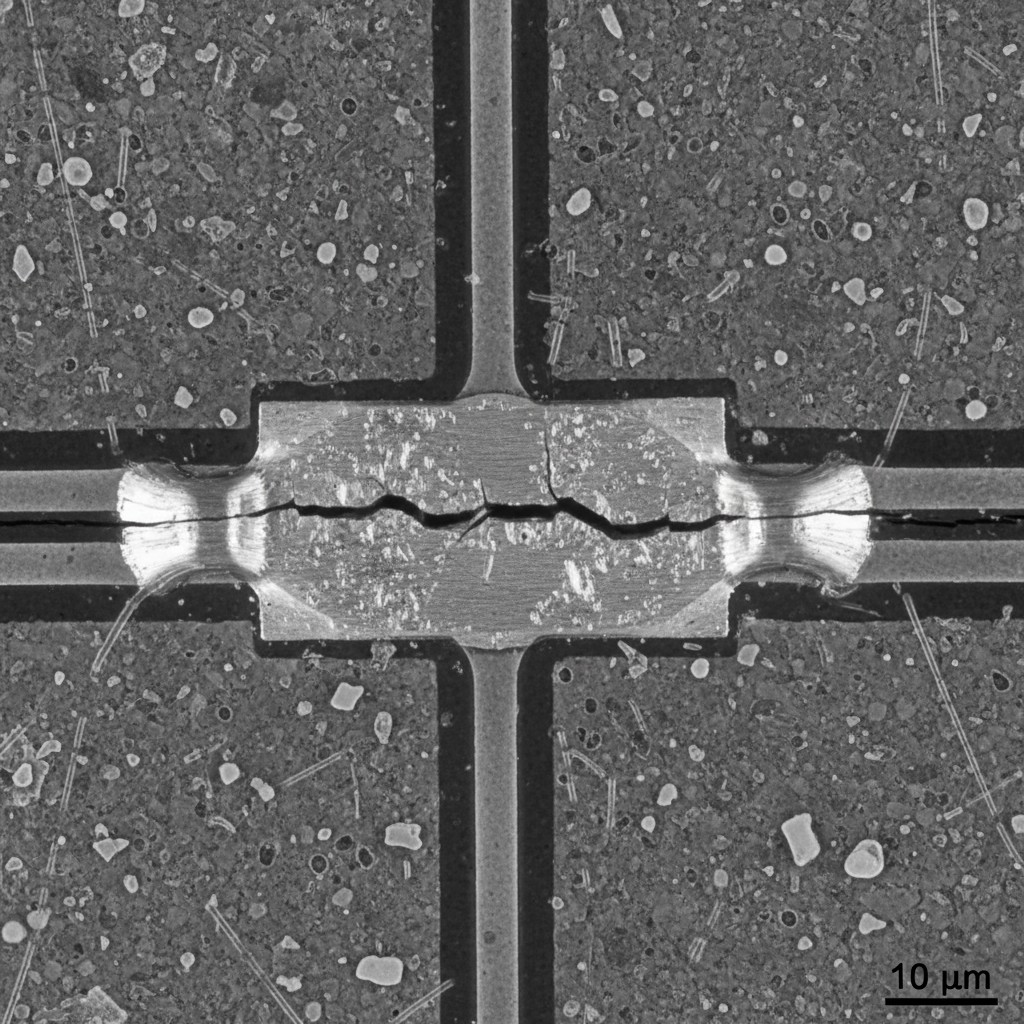

Vibration is a relentless mechanical stressor. Unlike a single shock event, continuous vibration drives cyclic flexion in the solder fillet. Each flex can initiate microscopic cracks where the solder meets the component or the pad. Over millions of cycles, these cracks propagate until the joint fails. The rate of failure is a function of stress, and for SMT assemblies, component mass and bond area are what control that stress.

Electronics in off-road equipment endure broadband vibration from rough terrain; rail systems transmit low-frequency vibrations that couple efficiently into PCBs. In both cases, the board flexes, and the solder joints must absorb that strain. The 0402 passive, with its minimal mass and tiny solder fillets, concentrates this stress into a fragile mechanical link.

The Physics of Resonant Stress

As a PCB vibrates, the inertial force on a component is the product of its mass and acceleration. This force becomes shear stress in the solder joints. One might assume a lighter component means less force, but the relationship isn’t that simple. A component with twice the mass but more than twice the bond area actually experiences lower stress per unit area of solder.

Here, the 0402 presents an unfavorable ratio. Its mass is small, but its solder joint area is disproportionately smaller, concentrating the stress. The thin solder fillet also lacks the geometry—like the concave meniscus profiles of larger joints—that helps distribute load evenly. The joint becomes brittle, vulnerable to cracking right at the intermetallic layer.

Mass and Footprint as Protective Factors

The 0603 component offers meaningful improvements. Its mass is roughly three to four times that of an 0402, while its pad area is about double. This combination dramatically reduces stress concentration and increases the fatigue life of the connection. Reliability testing per standards like MIL-STD-810 often reveals that 0402 assemblies fail at rates several times higher than 0603 assemblies under the same vibration profile.

In a consumer device with a two-year lifespan of gentle handling, the difference may be negligible. In an industrial controller expected to survive a decade of constant vibration, the 0603 footprint is not a luxury; it is a structural necessity. The solder joint is the component’s anchor, and its size determines whether it holds firm or becomes a latent fault waiting to express itself in the field.

The Rework Cost Curve

No production process is perfect. A certain percentage of boards will always require rework, especially in the low-volume, high-mix world of custom rugged electronics. The economic pain of that rework is not linear with component size. It follows a steep curve, and the 0402 sits at the most punishing end.

Manually soldering an 0402 component demands magnification, steady hands, and precise thermal control. The pads are so close that solder bridges are a constant risk. The component’s low thermal mass means a moment’s carelessness with a soldering iron can destroy it or delaminate the pad from the board. An experienced technician can do it, but it is slow and error-prone. An inexperienced one often turns a simple repair into a scrapped board.

Time, Difficulty, and Scrap Rate

Reworking an 0402 passive typically takes two to four times longer than an 0603. The task requires finer tools, lower temperatures, and often a hot air station. Every extra minute of labor is a direct cost. In a field service scenario, that cost is multiplied by travel time and equipment downtime. The 0603, by contrast, is manageable with standard tools. Its size and thermal mass are forgiving, which reduces rework time and increases the first-pass success rate.

This difficulty directly impacts yield. Tombstoning and placement errors drag down the percentage of boards that pass inspection without rework. When the rework itself is prone to failure, scrap rates climb. The cost delta compounds across every board that needs a touch-up. A 2% increase in scrap rate on a production run of 1,000 boards, each costing $50, is a $1,000 penalty. Add in the extra labor for rework, and the costs quickly eclipse any BOM savings.

Total Cost of Ownership: The Real Calculation

The bill of materials (BOM) cost for an 0402 component is fractions of a cent lower than for an 0603. For a board with hundreds of passives, this might add up to a few dollars. But in harsh-duty applications, BOM cost is often the smallest line item in the total cost of ownership.

Total cost includes assembly yield loss, production rework, field failures, and warranty service. For a product destined for a benign environment, these secondary costs are low. For a product facing vibration and field service, they dominate the equation.

Imagine a control system for a rail car. Using 0603s instead of 0402s adds $4 to the BOM. But the 0402 design suffers a 3% tombstoning rate, requiring rework that costs $3,000 in labor and leads to $15,000 in scrapped boards over a 500-unit run. The initial $2,000 BOM savings is dwarfed by an $18,000 penalty. Then, if just 1% of the 0402 boards fail in the field under warranty at a cost of $300 per service call, that’s another $1,500 lost.

The math is clear. The 0603 component is cheaper over the product lifecycle. The small BOM premium is an investment that pays for itself many times over in reduced rework, scrap, and field failures.

Making the Pragmatic Choice

The case for 0603 passives in rugged builds isn’t absolute, but it should be the default. A deviation toward 0402 should be a deliberate engineering decision, not a reflex. The choice hinges on a few key factors:

- Environmental Stress: If the design faces sustained vibration, thermal cycling, or field service, the 0603 provides an essential mechanical and economic buffer. For benign office or consumer applications, the calculus shifts.

- Rework and Service Strategy: If the product will be serviced in the field, the 0603 reduces the risk of rework-induced damage. If it’s a disposable, non-serviceable item, rework cost is irrelevant, but field failure cost remains.

- Production Volume: High-volume, tightly controlled assembly lines can mitigate some tombstoning risks for 0402s. Low-volume, high-mix production lacks that statistical control, making the 0402 a yield liability.

- Space Constraints: In rare cases where board area is the absolute, unyielding constraint, the 0402 may be the only option. This choice must be made with full awareness of the consequences, demanding mitigation through conformal coating, underfill, or simply accepting higher failure rates as a known trade-off.

The instinct to shrink footprints has served electronics design well. But in harsh-duty applications, that instinct is costly. The 0603 passive is not obsolete; it is a pragmatic recognition of mechanical and economic reality. The hidden costs of using 0402 components in rugged builds are no longer hidden. They are quantifiable, they are avoidable, and they point decisively toward a larger footprint.