What is Acrylic Resin

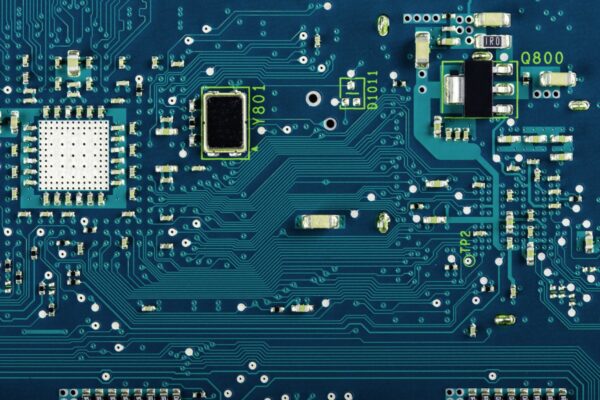

Acrylic Resin, also known as AR, is a thermoplastic substance that is derived from acrylic acid. It is produced in either a hydrocarbon solvent or an emulsion and is typically a one-part substance. Acrylic Resin is easy to apply and remove to any PCB assembly, making it a popular choice for conformal coatings. It dries to the touch at room temperature in minutes and has excellent electrical and physical properties.

Acrylic Resin is one of the more affordable coating options, but it has a low resistance to abrasions, making it unsuitable for harsh or high-temperature environments. However, it is fungus resistant and can easily be applied, making it a great choice when you need a short turnaround time. Acrylic conformal coatings are typically applied at 0.002 to 0.005 inches thick and cure in as little as 30 minutes.

In summary, Acrylic Resin is a preformed acrylic polymer that is dissolved in a solvent and used as a conformal coating for PCB assemblies. It is easy to apply and remove, has excellent electrical and physical properties, and is affordable. However, it is not suitable for harsh or high-temperature environments due to its low resistance to abrasions.

Frequently Asked Questions

What Resin Is Used in PCB

Epoxy and polyurethane resins are commonly utilized in PCBs as they provide exceptional insulation against harsh environments and also offer mechanical protection. These resins are applied in thickness to ensure maximum protection. Typically, these systems consist of two liquid components that rapidly increase in viscosity upon mixing until they are fully cured.

Why Is Resin Used in PCB

Resins are utilized in PCBs to provide protection and insulation to the components against extreme and difficult surroundings. By creating a barrier and encapsulating the device, resins serve the purpose of safeguarding the PCBs. Resins are often applied to PCBs with a thickness of 0.5 mm or more, and sometimes even thicker.

What Is the Purpose of Acrylic Conformal Coating

Acrylic conformal coatings are primarily used to shield circuits from moisture, dust, and fungus. They are preferred over other types of conformal coatings due to their affordability, user-friendliness, and reworkability.

What Is the Difference Between Silicone and Acrylic Conformal Coating

When it comes to conformal coating types, there are some differences between acrylic and silicone coatings. While acrylic coatings are known for their hardness, silicone coatings are more flexible and offer better mechanical shock resistance. Additionally, silicone coatings are designed to withstand harsher service environments, have better liquid water repulsion, and offer better chemical resistance. Overall, silicone coatings are soft, yet tough and durable, making them a great choice for a variety of applications.

What Are the Three 3 Types of Commonly Used Resin

The commonly used resin types are polyester, vinyl ester, and epoxy.

Why Is Resin Better Than Plastic

Compared to plastic, resin is a more environmentally friendly option because it is made from organic materials and is biodegradable. This means that it can be easily broken down into smaller pieces and is also recyclable. In contrast, plastic is made from synthetic fibers and contains fewer organic materials, making it more harmful to the environment.

What Is the Purpose of Resin

The resin serves several essential purposes, including facilitating stress transfer between the reinforcing fibers, binding the fibers together, and safeguarding them against mechanical and environmental harm. Thermoplastic or thermoset resins are commonly used in reinforced polymer composites.

How Do You Remove Resin From PCB

To remove resin from a PCB, one can use a soldering iron set to 500-600°F to heat the epoxy residue until it softens and loses adhesion. Then, it can be scraped off with ease. However, it is important to note that this method should only be used on surfaces that can withstand high temperatures and not on the PCB material itself.

What Are the Disadvantages of Acrylic Conformal Coating

Acrylic conformal coating may not be the most suitable option for applications that involve exposure to solvents, as it can be easily removed by weaker solvents like isopropyl alcohol or xylene. This is one of the major drawbacks of using acrylic conformal coating.

What Is an Advantage of an Acrylic Coating System

Acrylic coating systems offer a cost-effective solution with comparable durability to other types of coatings. This makes them a popular choice for building owners who want a long-lasting roofing system that reduces energy consumption and maintenance costs.

Is Acrylic Better Than Silicone

Although acrylic sealant can be painted, it is important to note that silicone sealant outperforms acrylic sealant in all other aspects.

Which Resin Is Best

For a long-lasting and tough clear coating or finish, the ideal choice would be an epoxy/diamine (cycloaliphatic) resin and hardener. On the other hand, if you desire a glossy finish with impressive effects, then epoxy/polyetheramine would be the better option.

What Is the Most Common Resin Used

Polypropylene (PP)

PP is widely recognized as the most commonly used plastic resin across the globe due to its exceptional properties. It offers excellent chemical and electrical resistance, high melting point, hardness, stress resistance, and elasticity. Additionally, it is highly appreciated for its insulation properties, making it a preferred choice in various industries.

What Is the Disadvantage of Resin

The primary drawback of resin is its tendency to turn yellow when exposed to excessive sunlight. However, our epoxy resin has been enhanced to resist yellowing caused by UV light, and keeping it away from direct sunlight can further reduce the risk of yellowing. Additionally, resin is susceptible to trapping air bubbles or dust, which can affect its overall quality.

What Is the Difference Between Resin and Acrylic

Acrylic pouring paint is a durable medium, but it is not as resistant as resin. Over time, the paint may chip or crack, whereas resin art is one of the most durable art forms that can be created. Once cured, resin is completely water-resistant and can withstand a fair amount of wear and tear.