Choosing a PCB surface finish can feel like a simple line-item decision, a place to shave a few cents off the bill of materials. On paper, Organic Solderability Preservative (OSP) looks like the thriftiest choice. It’s lead-free, easy to apply, and undeniably cheap.

But at Bester PCBA, we’ve seen this well-intentioned decision become the origin point for some of the most expensive and frustrating problems in production. For New Product Introductions (NPIs), staggered builds, and projects with even a hint of schedule uncertainty, the case against OSP isn’t a matter of preference. It’s a matter of project survival.

The Deceptive Math of OSP

The appeal of OSP is its simplicity. A water-based organic compound selectively bonds to copper, forming a razor-thin protective layer against oxidation before assembly. The process is faster and less expensive than metallic finishes, making it a tempting option for any cost-sensitive project.

This upfront saving is OSP’s entire value proposition. For a high-volume product that moves from fabrication to assembly in a single, lightning-fast pass, it can be a viable choice. The math works. But NPI is rarely that clean, and those initial savings create a hidden liability—a ticking clock that many engineering teams don’t hear until it’s too late.

The Invisible Clock: How OSP Betrays Solderability

Unlike a robust metallic finish, OSP is not a permanent barrier. It is a temporary shield, and its integrity is fragile. From the moment a board leaves the fab house, OSP begins to degrade, a process accelerated by two enemies: heat and time. This isn’t a defect; it is the fundamental nature of the finish.

The First Heat Cycle: Primed for Failure

Most modern boards require assembly on both sides. The first reflow cycle, which solders components to the primary side, exposes the entire board to extreme temperatures. This heat compromises the unused OSP-coated pads on the board’s secondary side. The organic layer partially degrades, leaving the copper underneath exposed and far more susceptible to oxidation.

The Shelf Life of Solderability

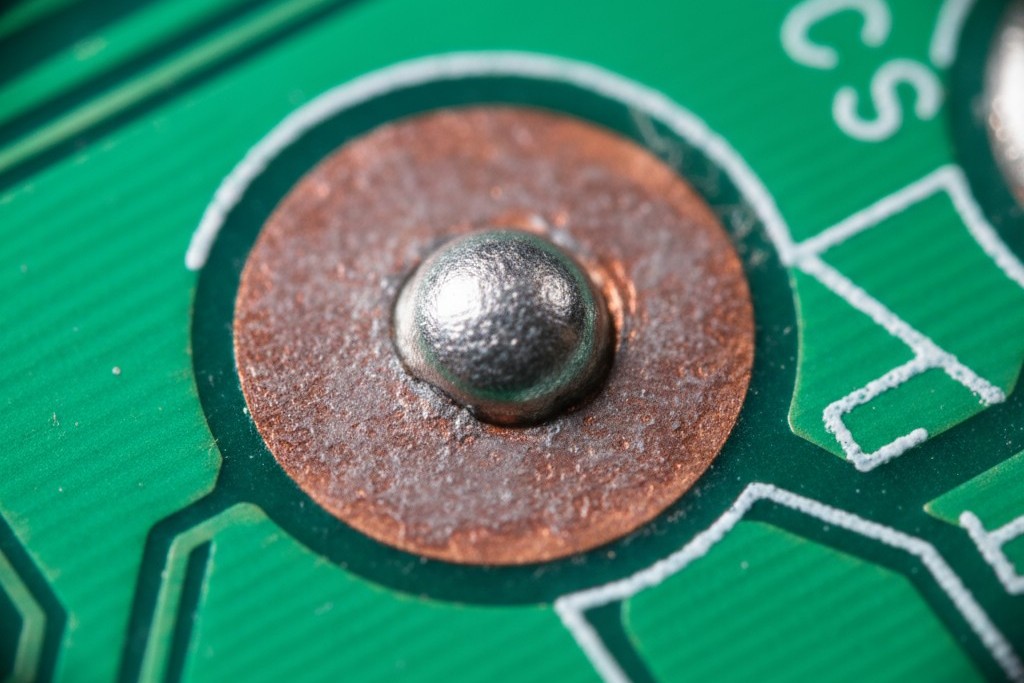

Once degraded by heat or simply exposed to the atmosphere over a few weeks, the underlying copper begins to oxidize. Even a microscopic layer of copper oxide on the pad is enough to prevent a reliable solder joint. When the board finally returns for its second assembly pass, the solder paste cannot form a proper intermetallic bond. The solder fails to wet the pad, resulting in weak joints, open circuits, and outright assembly failure.

With OSP, the clock is always ticking. A few weeks on a shelf or an unexpected delay in sourcing one critical part is all it takes to turn a pristine PCB into a soldering disaster.

When Ideal Scenarios Meet NPI Reality

Defenders of OSP point to its success in tightly controlled, high-velocity manufacturing. If a board is fabricated and fully assembled within days, OSP performs adequately. The window of solderability remains open.

This is a fantasy in the world of New Product Introduction. NPI is defined by uncertainty. Schedules are fluid. A key component faces a supply chain delay. A design revision puts a subset of boards on hold. Builds are staggered, with a portion of the lot assembled immediately and the rest held for later. In these common scenarios, OSP is a gamble. The boards sitting on the shelf are not static assets; they are actively degrading.

The Anatomy of a Rework Loop: Where Savings Evaporate

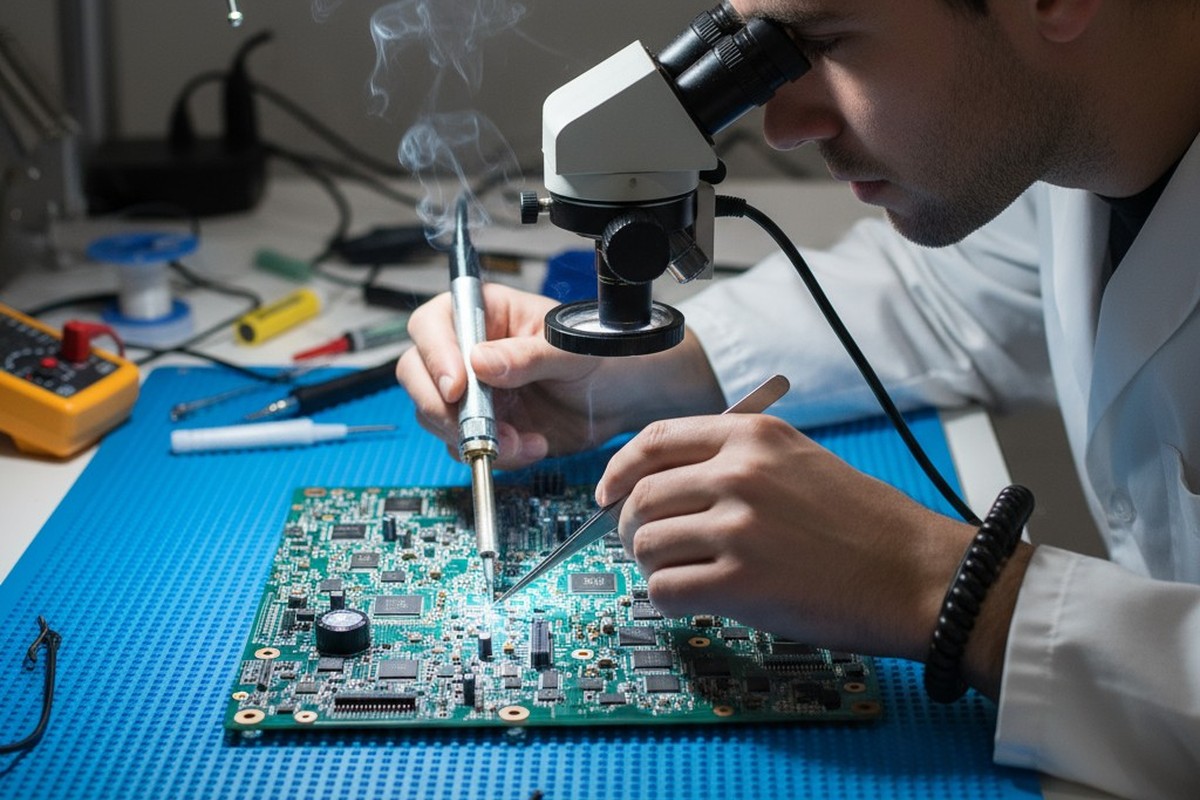

The true cost of OSP is revealed not on the fabrication quote, but on the assembly floor. When the oxidized pads on the second side of the board go through reflow, the failures cascade. Automated Optical Inspection (AOI) flags dozens of bad joints. A simple-looking board suddenly requires hours of painstaking manual rework.

This is where the penny savings vanish. A technician must now diagnose the opens, carefully desolder nearby components for access, meticulously clean the oxidized pad, and attempt to hand-solder the part. The process is slow, expensive, and risks damaging the board or adjacent components. A single complex BGA that fails to solder can cost more in rework and potential scrap than upgrading the finish on the entire batch of boards.

The initial savings are a mirage.

The Case for Sanity: Why ENIG is the NPI Standard

Faced with the inherent risk of OSP, the pragmatic choice for NPI is Electroless Nickel Immersion Gold (ENIG). While its upfront cost is higher, it isn’t an expense; it’s an insurance policy against catastrophic failure. At Bester PCBA, we consider it the default professional choice for protecting a project’s timeline and budget.

A Finish Built for Uncertainty

ENIG’s structure is fundamentally robust. A layer of nickel is plated over the copper, creating a durable, non-porous barrier. A whisper-thin layer of immersion gold then protects the nickel from oxidizing. This structure is not sensitive to time like OSP. An ENIG board can sit on a shelf for a year and its solderability will be virtually unchanged.

Flat, Stable, and Predictable

The nickel-gold stack is highly resistant to heat. It withstands multiple reflow cycles without degradation, ensuring the pads on the second side of the board are just as solderable as the first. Furthermore, ENIG provides an exceptionally flat, or planar, surface—critical for reliably soldering fine-pitch components and large BGAs. This predictability removes an entire class of variables from the complex NPI assembly process.

A Pragmatic Framework for Choosing Your Finish

The decision isn’t about which finish is universally “better,” but which is appropriate for your project’s risk profile. Our guidance is based on managing total cost, not initial price.

ENIG should be the default choice for any project involving NPI, high-value components, or an uncertain schedule. The premium paid is minimal compared to the budget-destroying potential of a single rework loop. You are paying for predictability and a wider process window. You are paying for peace of mind.

If you are absolutely constrained by budget and must use OSP, treat the boards like perishable goods. Implement strict first-in, first-out inventory rules, store them in a nitrogen dry box, and communicate the tight assembly window to your manufacturing partner. These are merely workarounds for a risk that could have been designed out from the start. In manufacturing, the choices that look thrifty upfront often exact the highest price.