The tension is familiar. You need rapid New Product Introduction (NPI) builds to validate designs, iterate quickly, and beat competitors to market. But you also need those same designs to scale into stable, repeatable mass production without starting over. Most contract manufacturers force a choice: rapid prototyping plagued by chaos, or disciplined production with glacial NPI cycles.

At Bester PCBA, we deliver both. The difference isn’t heroic effort or wishful thinking; it’s architecture. We’ve built our entire process around dedicated NPI cells, embedded early DFM checkpoints, and instituted a golden sample lock-in protocol that creates a clean, unbreakable bridge from prototype to production. This isn’t a marketing claim. It’s a methodology, and the mechanics are what determine whether your product succeeds or stumbles when volumes ramp.

Why NPI and Production Are Opposing Forces

New Product Introduction and mass production aren’t just different in scale. Their operating requirements are fundamentally incompatible. Understanding this conflict is the only way to solve for both.

NPI exists to answer questions. It demands iteration, rapid changes, and the flexibility to pivot when a design assumption fails. The point of an NPI build is to learn—to test a hypothesis, find failure modes, and incorporate changes on the fly. Speed is everything. You need answers now, not next quarter.

Production, by contrast, exists to eliminate questions. It requires locked processes, frozen documentation, and flawless execution at volume. Every variable is controlled; every step is optimized for throughput, yield, and cost. The goal is efficiency and predictability. Stability is the primary constraint, and changes are expensive disruptions.

Try to run both on the same line, and you destroy both. NPI work interrupts production schedules, killing throughput with costly changeovers. Production discipline strangles NPI, burying rapid iteration under a mountain of change control. Operators trained for high-volume consistency are frustrated by variety; operators who thrive on variety can’t maintain the discipline for high-yield production. The result isn’t a compromise. It’s chaos.

The cost of this chaos is real. We’ve seen clients arrive after NPI delays stretched for weeks because production schedules took priority, or where production yields collapsed because undisciplined prototype practices bled into the main line. The failure is predictable. When you force incompatible processes to share resources, you get the worst of both worlds. The only structural solution is separation.

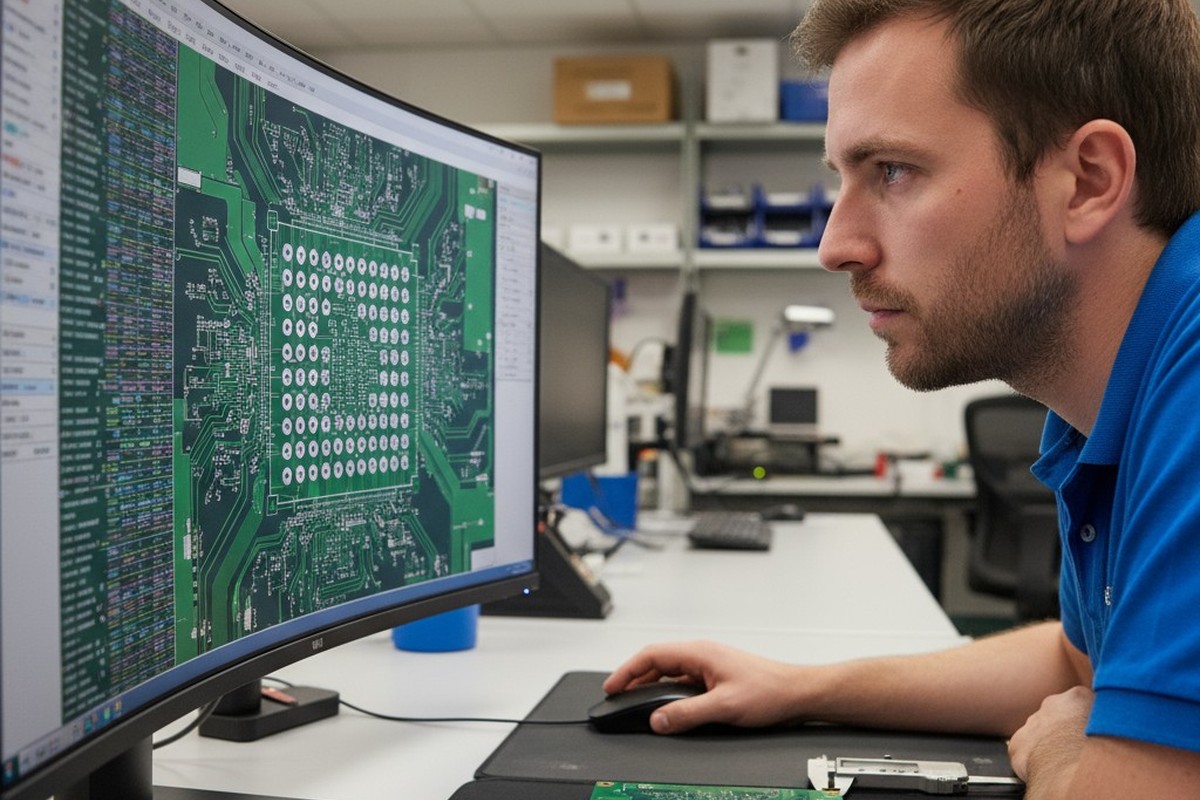

The Dedicated NPI Cell Architecture

At Bester PCBA, our NPI cells are physically and operationally isolated from our production lines. This isn’t a shared-resource model where NPI squeezes into production downtime. It’s a parallel architecture where NPI has its own space, its own equipment, its own schedule, and its own rules. This separation makes both speed and discipline possible.

Physical and Process Isolation

Physical isolation means our NPI cells are separate manufacturing areas with an independent workflow. When an NPI build arrives, it doesn’t wait for a production run to finish or compete for line time. It enters a cell already configured for variety and rapid setup. Production lines run on optimized schedules driven by volume commitments; NPI cells run on flexible schedules driven by client timelines. There is no conflict because there are no shared constraints.

Process isolation means NPI cells operate under different rules. Production lines enforce strict change control, where any deviation requires formal approval. NPI cells expect change. We build flexibility into the workflow, anticipating that a build might reveal an issue requiring immediate modification. This isn’t chaos; it’s a structured process designed to absorb iteration without the overhead that would paralyze production. The result is fast cycles for NPI and undisturbed efficiency for mass production.

Specialized Tooling and Operator Skills

NPI cells are equipped differently. The tooling prioritizes flexibility over throughput, with equipment that handles rapid changeovers and supports a wide variety of board sizes and component types. Production lines, conversely, are optimized for long, identical runs. The equipment reflects the goal.

The operators in our NPI cells are specialists in variety. They are trained to interpret new designs quickly, troubleshoot unfamiliar assembly challenges, and adapt on the fly. This is a different skill set than that of production operators, who are masters of speed, consistency, and adherence to locked processes. Both are essential, but they are not interchangeable. By staffing NPI cells with operators who thrive on novelty, we enable the rapid problem-solving that NPI demands.

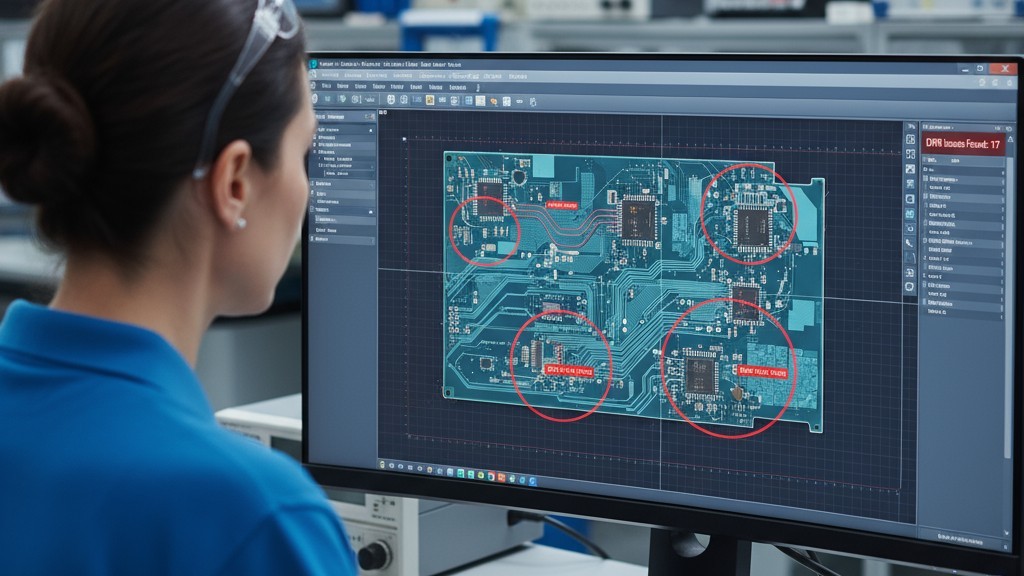

Early DFM Checkpoints That Prevent Expensive Failures

Speed is only valuable if the builds work. That’s why we run a structured Design for Manufacturability (DFM) analysis before committing to a first build. This is not a courtesy review; it’s a formal stage gate that happens early, before materials are ordered and before a client invests in tooling. The goal is to catch expensive failures when they are still cheap to fix.

Our DFM checkpoints target the failure modes we see most often in the transition to production: designs that are buildable as prototypes but collapse at volume, use components with critical availability problems, or make inspection and testing impossible. We check for these before the first board is ever built.

Design Rule Verification: It starts with the fundamentals. We validate that the design adheres to IPC standards and our own manufacturing capabilities for trace width, spacing, via sizes, and solder mask tolerances. A design that violates process limits will either fail outright or require costly workarounds. Catching this early means the designer can make a simple adjustment in CAD, not after tooling is committed.

Component Availability and Lifecycle Analysis: We verify every component in the Bill of Materials (BOM) for availability, lead times, and lifecycle risks like obsolescence or single-source dependencies. Availability problems are the number one cause of schedule delays in NPI. If a part has a 16-week lead time or is flagged for end-of-life, we surface that immediately.

Testability and Inspection Access: We review the design for test point accessibility and clearance for probe access. A board that can’t be tested or inspected effectively will have yield problems in production, even if the prototypes work. We ensure the design supports our AOI and functional test processes, flagging areas where hidden joints create risk.

Thermal Management and Impedance Control: We analyze thermal dissipation for power components and verify that high-speed signal routing meets impedance requirements. These are the kinds of subtle issues that don’t always surface in a small NPI build but cause field failures at scale.

Skip this stage, and the first failure happens on the line. The fix requires a design change, a new material order, and a complete restart of the timeline. An NPI cycle that should have taken two weeks stretches to six. It’s a pattern we’ve seen too often, and it’s why we treat DFM as non-negotiable.

The Golden Sample Lock-In Protocol

Once a design passes DFM review and completes a successful NPI build, we initiate the golden sample lock-in. This is the control mechanism that bridges the gap to production. A “golden sample” is a physically validated reference board representing the exact design, materials, and processes that will be replicated at scale. It’s not just a prototype; it’s the frozen standard against which all future production units will be measured.

The approval process is formal. We build the sample using the DFM-validated documentation. The client inspects and tests it to verify all functional, electrical, and cosmetic requirements. Once approved, we lock the design. The Gerber files, BOM, assembly instructions, and process parameters are frozen and archived as the production baseline.

This protocol eliminates ambiguity. Production doesn’t interpret or improvise; it replicates. When a production order arrives, the line uses the locked documentation from the golden sample. There is no guessing about design revisions, no debate over component substitutions, and no uncertainty about process settings. The golden sample is the single source of truth, enabling repeatable, high-yield production. The lock-in is comprehensive, freezing everything that affects the final product: design files, the BOM with exact part numbers, and the assembly and test procedures with defined parameters and acceptance criteria.

Managing Revisions After Lock-In

The lock-in isn’t a prison. Designs evolve. If a change is required after golden sample approval, it triggers a formal Engineering Change Order (ECO). We evaluate the impact, and if the change is approved, we build and validate a new golden sample. The old revision is archived, and the new one becomes the production baseline. This controlled process prevents informal changes from propagating through production, a common source of version confusion and yield problems.

The Complete Data Package for First-Pass Success

A golden sample is only as good as the data that defines it. We require a complete data package before we commit to an NPI build, because incomplete data is the most common—and most preventable—cause of delays. The gaps are predictable: missing files, ambiguous specifications, or BOMs that lack procurement details.

A complete package has four core elements:

Gerber Files: They must be pristine. We require the RS-274X format with all layers clearly labeled. Ambiguity here causes fabrication errors that are expensive to fix after the fact.

An Intelligent BOM: This is more than a parts list. We need manufacturer part numbers, quantities, reference designators, and any approved alternates. A BOM that just lists “10uF capacitor” is unusable.

Clear Assembly Drawings: These must include critical dimensions, polarity indicators, connector orientation, and callouts for any special handling requirements. Production operators follow the documentation; ambiguity results in defects.

Defined Test Requirements: We need to know the functional test points, acceptance criteria for electrical parameters, and any applicable cosmetic standards. A data package that omits test requirements forces us to make assumptions, and assumptions create risk.

Even with a perfect data package, first-pass NPI yield is rarely 100 percent. Builds surface issues that can’t be predicted in a design review, like a component footprint mismatch or a reflow profile that needs a minor tweak. That’s why NPI exists. A complete data package eliminates the preventable failures, ensuring that any issues we find are genuine learning opportunities, not symptoms of a documentation problem.

The Smooth Path from NPI to Production

Our NPI process is designed with the end in mind. Every checkpoint and documentation requirement exists to make the transition to production seamless. When an NPI build is complete and the golden sample approved, the path to production isn’t a new negotiation; it’s a continuation of the same validated process.

The transition to a production line happens when volumes justify it, whether that’s 50 units or 5,000. Readiness isn’t about volume; it’s about stability. Has the design been validated? Is the golden sample locked? Is the data package complete? If so, the transition is straightforward. The production line uses the same locked documentation, approved materials, and process parameters validated in the NPI cell. There is no re-interpretation and no starting over.

The process transfer is a formal handoff. The NPI documentation package is delivered to production planning, and any lessons learned are communicated. The first production run is monitored closely to verify that yield and quality match the NPI baseline, but this is verification, not redevelopment. This is why the upfront rigor matters. The dedicated cells, DFM checks, and golden sample are not bureaucratic overhead. They are the foundation that makes scaling not just possible, but predictable.