Component shortages are a painful, cyclical reality in electronics. Allocations tighten, lead times stretch into oblivion, and production lines grind to a halt. In these moments, turning to the open or “broker” market feels like the only way to keep a project alive.

But that path is fraught with risk.

At Bester PCBA, we operate on a simple principle: shortages happen, but excuses for shipping a faulty product do not. When authorized distribution channels fail and a broker buy is the only path forward, we don’t rely on hope or paperwork. We enforce a series of mandatory guardrails to protect our clients’ products and reputations.

The Shortage Is a Reality; The Risk Is a Choice

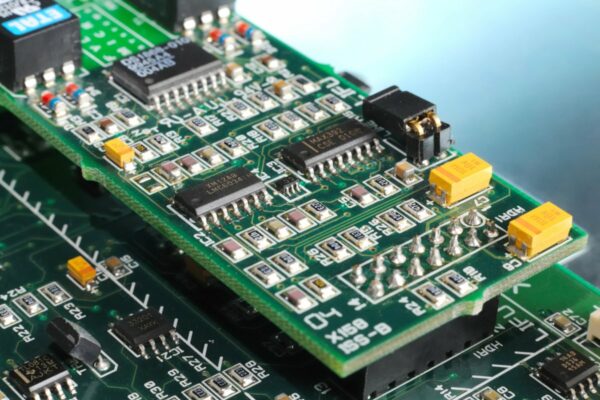

Authorized distributors have a direct, contractual relationship with component manufacturers, ensuring a clear chain of custody and authentic parts. Brokers operate in the open market, buying excess inventory from countless sources. While many are legitimate, this world lacks the inherent traceability of authorized channels, making it the primary entry point for counterfeit, remarked, and substandard components.

When we are forced to source from this market, we treat it as an engineering challenge. The risk of receiving a fraudulent part isn’t a possibility to be dismissed; it’s a probability to be managed. Accepting a shipment of brokered components without rigorous, physical verification is not a calculated risk. It is a choice to gamble with the final product.

Why Certificates of Conformance Aren’t Enough

The most common and dangerous misconception is that a Certificate of Conformance (C of C) provides adequate protection. In the world of authorized distribution, a C of C is a reliable document tracing a part directly back to the original manufacturer. It carries weight because the chain of custody is unbroken.

With brokered components, that chain is shattered. A C of C can be easily forged, altered, or may belong to an entirely different batch of authentic parts while the components in the box are fraudulent. It becomes a piece of paper, detached from physical reality. Relying on it is an exercise in liability transfer, not risk mitigation.

It’s a paperwork game. We don’t play it.

Our Mandated Playbook for Brokered Components

So if paperwork is worthless, what isn’t? Empirical, physical evidence. We have developed a non-negotiable, multi-layered playbook for every single brokered component that enters our facility. These are not optional checks; they are mandatory gates a component must pass before it is ever considered for a client’s board.

Layer 1: Verifying the Material with XRF Alloy Analysis

First, we answer a basic question: what is this component actually made of? Counterfeiters often cut costs by using incorrect alloys or ignoring RoHS standards. A part sold as lead-free might contain lead, or the termination plating might be the wrong material, leading to poor solderability and long-term reliability issues.

We use X-Ray Fluorescence (XRF) analysis on samples from every batch to determine their precise elemental composition. This non-destructive test instantly reveals if the materials match the manufacturer’s specifications. If the alloy is wrong, the investigation stops. The entire lot is rejected.

Layer 2: Inspecting the Core with Sample Decapsulation

If the material is correct, we move to the next layer of scrutiny: is the component what it claims to be on the inside? It is common for counterfeiters to take a cheap, low-spec component and “remark” it to look like a more expensive, high-performance one. The package looks right, but the silicon die inside is a fraud.

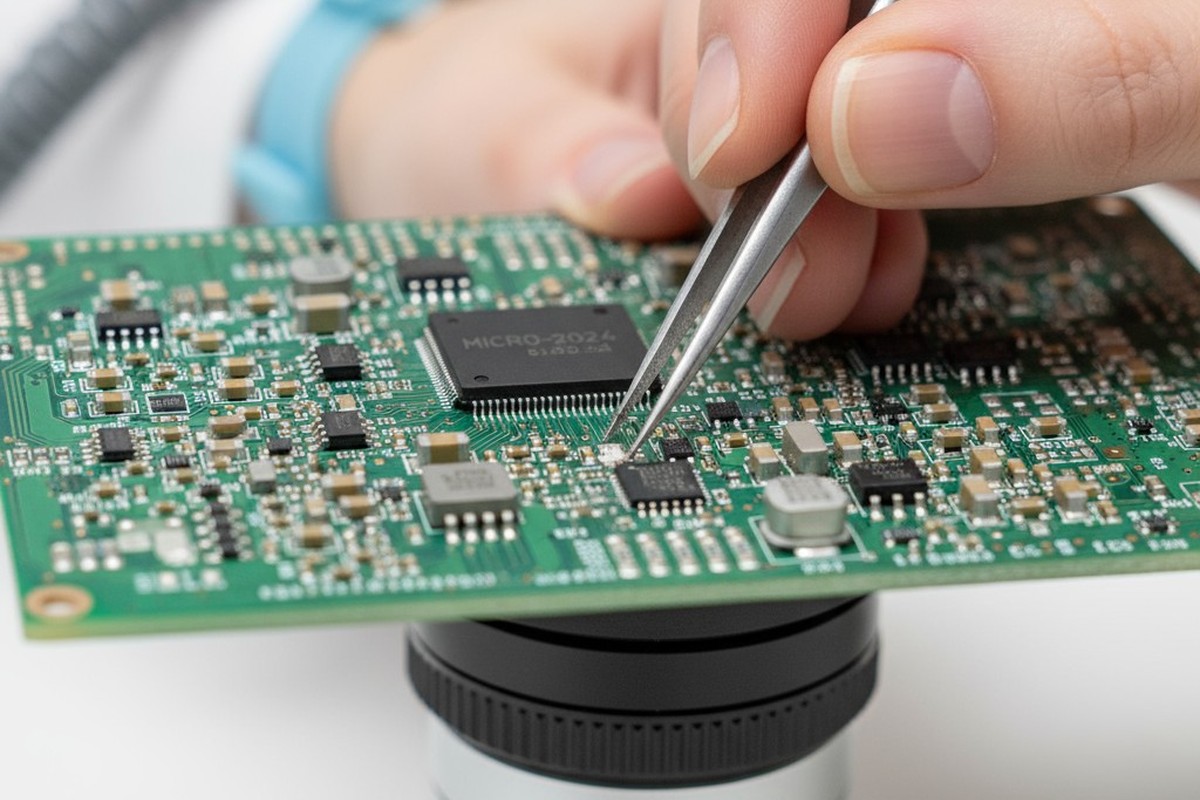

To verify the die, we perform decapsulation on a sample. This destructive process uses acid to dissolve the component’s packaging and expose the bare silicon. We then inspect the die’s architecture and markings under a high-powered microscope, comparing it against a known-good example. This is the only way to be certain the functional core of the component is authentic.

Layer 3: Challenging the Surface with Marking Permanency Tests

Even with a correct die, a part can be fraudulent. Used or old-date-code components are often “blacktopped”—resurfaced with a black coating—and given fresh markings to appear new. These parts may have been poorly handled or exposed to electrostatic discharge, making them ticking time bombs.

To detect this, we perform solvent and heat tests on the part markings. A gentle wipe with specific solvents or the application of heat will often smudge, fade, or completely remove the fake markings of a remarked component. Original factory markings remain pristine. It is a simple but brutally effective test of authenticity.

The Final Safeguard: Quarantine and Provenance

Components that pass all three layers of physical testing are not immediately released to production. They are placed in a secure quarantine area, physically and systemically segregated from our general inventory.

While testing is underway, our procurement team works to establish as much provenance as possible. A full chain of custody is impossible in the broker market, but we gather all available documentation and intelligence on the source. Only when parts have passed all physical tests and all procedural checks are cleared do we release them from quarantine. This ensures a final, deliberate review before they are committed to a build.

An Engineering Problem, Not a Paperwork Game

This level of diligence has a cost. The equipment is expensive and the process takes time. But the cost of a single product failure in the field—in recalls, reputational damage, and lost customer trust—is orders of magnitude higher. The cost of testing is an investment; the cost of not testing is an unacceptable liability.

At Bester PCBA, we believe managing supply chain risk is fundamentally an engineering problem. It demands empirical evidence, physical testing, and a systematic process. It cannot be solved by shuffling papers or hoping for the best. When we navigate the uncertainties of the open market, we do so with the discipline and rigor our clients deserve.