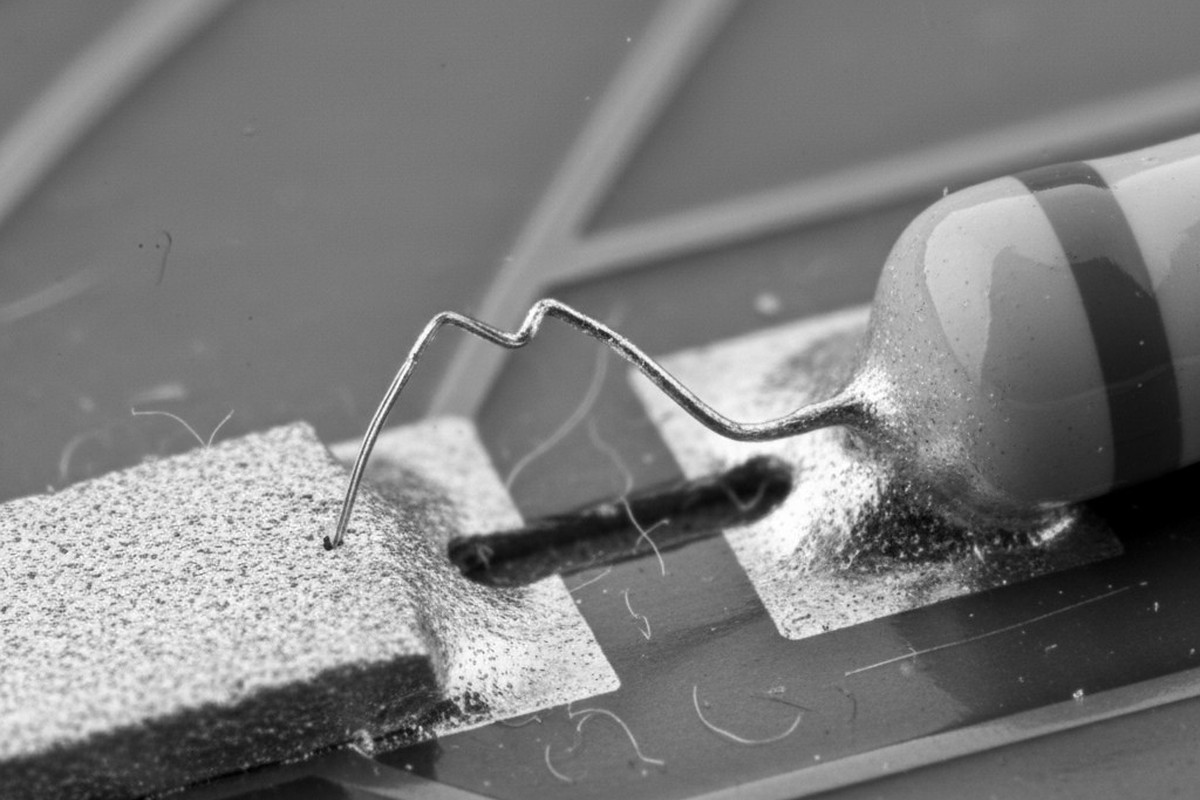

A product designed for a long, quiet life sits on a shelf, sipping milliamps from a battery. It’s a sensor, a monitor, a piece of infrastructure meant to be installed and forgotten, operating in a climate-controlled room that hovers around a comfortable 30°C. Years later, it fails without warning. The culprit isn’t a faulty component or a software bug. It’s a microscopic metal filament that grew silently over time, creating a short circuit where none should exist.

This is a frustrating reality for engineers. Conventional wisdom suggests tin whiskers—electrically conductive, crystalline structures that erupt from tin-plated surfaces—are a problem for high-stress environments. Yet we see them causing latent failures in the most benign applications: always-on, low-current nets on boards that never see significant thermal or mechanical shock. This quiet, room-temperature environment is not a safe zone. It’s an ideal incubator for this insidious failure mode.

Understanding the Enemy: The Unpredictable Nature of Tin Whiskers

Tin whiskers are not a product of corrosion or contamination. They are a manifestation of physics, growing directly from the plated surface itself.

What Are Tin Whiskers and How Do They Form?

A tin whisker is a spontaneous, hair-like growth of monocrystalline tin. These filaments can grow several millimeters long but remain only a few micrometers in diameter. Despite their minuscule size, they are strong enough to carry several amps of current before melting, a significant threat in modern electronics where component spacing is measured in mils. They grow unpredictably over months or years, creating a latent risk of short circuits between adjacent pads, traces, or component leads.

The Role of Compressive Stress as the Engine of Growth

The primary driver for tin whisker growth is compressive stress within the tin plating. This pressure can originate from the plating process itself, from stresses induced by the underlying copper substrate, or from external mechanical forces. To relieve this internal pressure, the tin plating seeks the path of least resistance. Instead of deforming uniformly, it expels material at weak points in its grain structure. This migration of atoms, fueled by the stored energy of compressive stress, results in the slow, persistent eruption of a whisker.

The 30°C Deception: A Perfect Storm for Whisker Formation

The most dangerous misconception is that a lack of extreme temperatures or mechanical stress equates to a low-risk environment. For low-power sleeper devices, the opposite is often true. A steady, room-temperature condition around 30°C (86°F) creates a uniquely hazardous “sweet spot” for whisker growth.

Why Room Temperature Is Not a ‘Safe Zone’

Whisker formation is a battle between compressive stress and the atomic mobility required for atoms to move. At very low temperatures, atomic mobility is too low for whiskers to grow, even if stress is present. At very high temperatures (above 100°C), the tin layer can effectively anneal itself, relieving stress through recrystallization before whiskers can form.

The 30°C to 50°C range is the danger zone. It provides just enough thermal energy to give tin atoms the mobility they need to migrate and build a whisker, but it’s not hot enough to relieve the underlying compressive stress in the plating. The environment is active enough to fuel growth but too passive to trigger natural stress relief.

How Low-Current ‘Always-On’ States Create Ideal Conditions

Low-power, always-on circuits contribute to this perfect storm. Unlike high-power circuits that generate significant heat and create their own thermal cycles, these “sleeper” nets provide a constant, low-level thermal energy that keeps the board in that ideal whisker-growth temperature window. There are no significant temperature swings to help redistribute stress, only a steady state that allows the slow, methodical process of whisker formation to proceed uninterrupted for years.

The Decisive Factor: Choosing a Whisker-Resistant Plating System

While design factors can help, the choice of surface finish is the single most important decision an engineer can make to mitigate tin whisker risk. No compromises should be made here for products requiring a long service life.

The Failure of Pure Tin Finishes

Following RoHS regulations, pure tin finishes became a common, low-cost replacement for lead-based solders. For high-reliability applications, this was a mistake. Pure tin, especially bright tin with its fine grain structure and high internal stress from the plating process, is exceptionally prone to whisker formation. Any design specifying a pure tin finish for a long-life product embeds a latent failure mode from the start.

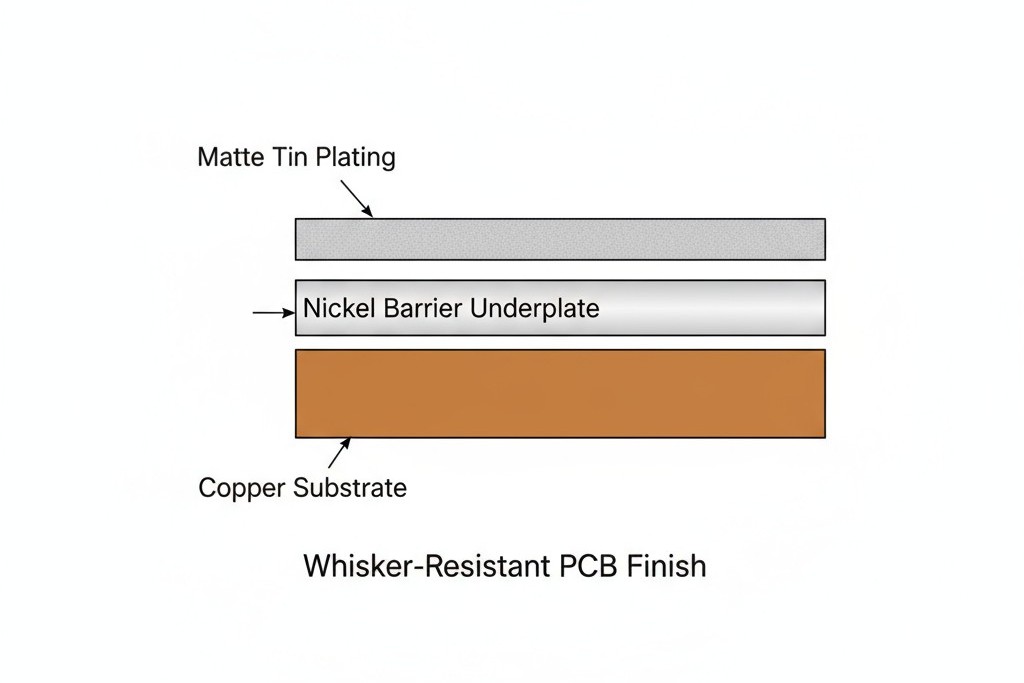

Our Recommended Solution: Matte Tin, Nickel Underplate, and Anneal

A multi-part system is the only reliable defense. We strongly recommend a finish composed of matte tin plated over a nickel under-barrier, followed by a post-plating annealing process.

Each component serves a critical function. Matte tin has a larger grain structure and inherently lower internal stress than bright tin, reducing the primary driving force for whisker growth. The nickel underplate acts as a crucial barrier, preventing the formation of copper-tin intermetallic compounds (IMCs)—a major source of compressive stress. Finally, a post-plating anneal, typically baking the boards at 150°C for one hour, relieves any remaining internal stresses from the plating process itself.

Evaluating Secondary Defenses and Common Misconceptions

While plating is the primary defense, other strategies are often discussed. It is vital to understand their limitations and not mistake them for a complete solution.

The Limits of Conformal Coating Against Whisker Penetration

A common belief is that conformal coating can simply contain any whiskers that form. This is a dangerous assumption. A growing whisker exerts significant pressure at its tip and will puncture many types of soft coatings over time. Even if it fails to puncture the coat, a whisker can grow underneath it, pushing it upwards, or find its way through porous areas. While a thick, hard coating like epoxy may offer some resistance, it should never be the primary mitigation strategy. It is a secondary defense, at best.

The Supporting Role of Guard Traces and Strategic Spacing

Good design practices can reduce the consequences of a whisker, even if they cannot prevent its formation. Maximizing spacing between conductors, especially for fine-pitch components, makes it harder for a whisker to bridge a gap. For critical nets, incorporating grounded guard traces can provide a safe path to ground, potentially preventing a short between two active signals. These are useful risk-reduction techniques, but they do not address the root cause.

A Pragmatic Playbook for Long-Term Reliability

Preventing silent field failures from tin whiskers is not a matter of luck; it is a matter of deliberate engineering. The playbook is straightforward: address the root cause, not the symptoms. The most critical decision is made at the fabrication stage, long before any components are placed.

For any product that must operate quietly and reliably for years, the surface finish is paramount. A system using matte tin with a nickel underplate and a proper anneal cycle is the most effective strategy available. Relying on pure tin is an unacceptable risk. Believing conformal coating will save a poor plating choice is a recipe for failure. Guard traces and spacing help, but the right plating choice is what ensures a long, quiet life.