Component obsolescence is more than an inconvenience; it’s a critical threat to the lifecycle of a proven product. When a vital Ball Grid Array (BGA) is no longer available in a lead-free format, but your assembly line has moved on from lead, you face a dangerous gap. The only part you can find is leaded, your process is lead-free. It’s a collision of old and new where the path of least resistance leads directly to failure. Many are tempted to simply solder the leaded component onto the lead-free board. This isn’t a calculated risk—it’s a guaranteed compromise. The metallurgy is fundamentally incompatible. A product’s future depends on its components, and that requires an engineering solution, not a shortcut. That solution is controlled component reballing, a process that safely converts obsolete parts into modern, reliable assets.

The Unseen Failure: Why Mixing Leaded BGAs and SAC Solder Is a Non-Starter

Using a leaded BGA in a lead-free SAC (Tin-Silver-Copper) assembly might seem pragmatic, but it introduces unacceptable metallurgical chaos into any professional-grade product. The failure isn’t always immediate, but it is inevitable, and it begins deep within the solder joint itself.

The Metallurgy of a Compromised Joint

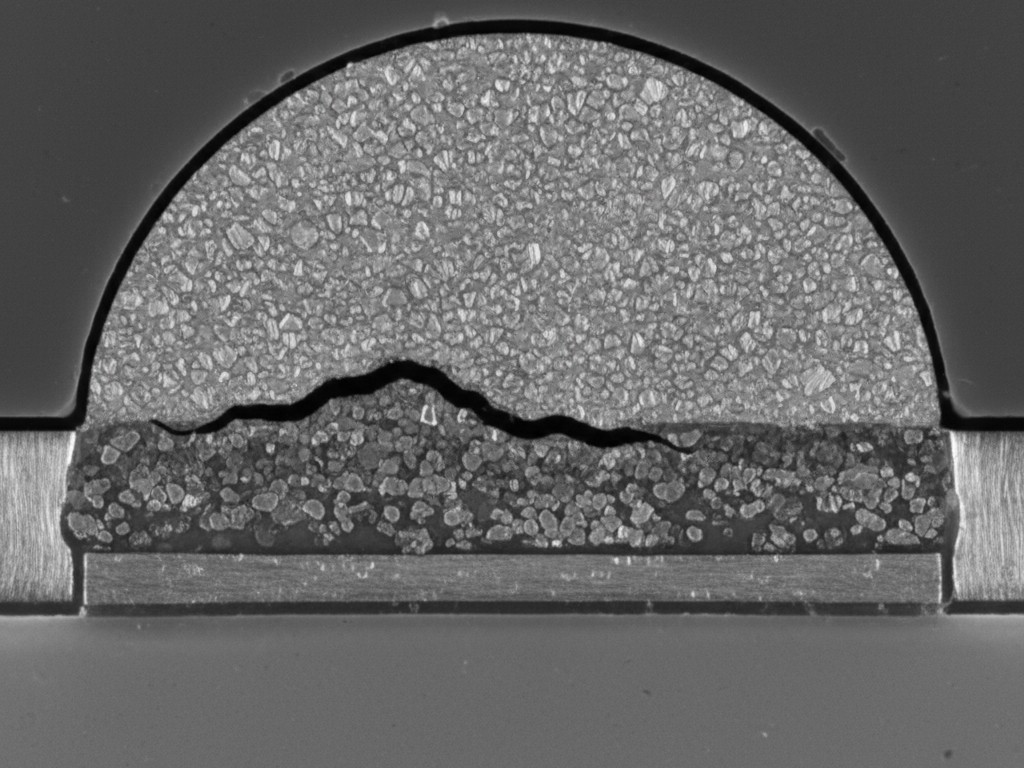

When molten leaded solder (Tin-Lead) mixes with lead-free SAC paste during reflow, the resulting alloy is an unpredictable cocktail, not a happy medium. The complex interaction of tin, lead, silver, and copper creates a wide range of intermetallic compounds (IMCs). Unlike the well-characterized IMC layers formed in a pure process, these mixed-alloy IMCs are notoriously brittle and poorly structured.

From Brittle Intermetallics to Thermal Cycle Failure

This brittleness is a hidden defect waiting for a trigger. As the product experiences thermal cycles in the field—heating up and cooling down—the PCB and the BGA expand and contract at different rates, stressing every solder ball. In a properly formed joint, ductile solder and well-structured IMCs absorb this stress for thousands of cycles. In a compromised joint, the brittle IMCs cannot. They crack. These microfractures propagate over time, leading to an open circuit and catastrophic field failure. This is a hidden failure, born from a shortcut you cannot afford.

The Flawed Alternatives: Debunking Common Shortcuts

Faced with this challenge, some engineers search for an intermediate fix, often trying specialized solder pastes or modified reflow profiles. The logic is that a different flux or a longer soak time might help the incompatible alloys mix. This is a fundamental misunderstanding of the problem. While a highly active flux can clean surfaces and a complex thermal profile can influence wetting, neither can alter the underlying physics. The final, solidified joint will still be a blend of leaded and lead-free metals, containing the brittle, unpredictable intermetallic structures that cause premature failure. There is no solder paste that can safely bridge this divide. It is a materials science problem that demands a materials science solution.

The Engineering Solution: Converting Alloys Through Controlled Reballing

The only way to solve alloy incompatibility is to eliminate it. This is the principle behind BGA reballing. The process doesn’t try to join dissimilar metals; it replaces the problematic solder spheres with new ones that perfectly match the target assembly process.

The Principle of Full Alloy Conversion

Reballing is a process of restoration. The original leaded solder balls are methodically removed, the pads are meticulously cleaned, and new, lead-free SAC305 spheres are precisely attached. The result is a component that is, from a soldering perspective, identical to a new, factory-produced lead-free BGA. It can enter your standard SAC assembly process without compromises, special profiles, or metallurgical risk.

More Than Just Replacing Spheres

Effective reballing is a multi-stage, micro-manufacturing process demanding immense control and specialized equipment. Each step is an opportunity for failure if not executed perfectly. A reliable outcome is defined entirely by the quality and control of the process used to achieve it.

The Bester PCBA Process: A Blueprint for Reliability

A reballed component is only as reliable as the process that created it. We’ve engineered our service as a series of controlled, validated steps that mitigate risk and guarantee a successful conversion.

Component Preparation and Moisture Control

Many BGAs are Moisture Sensitive Devices (MSDs). Absorbed humidity can vaporize during thermal excursions, causing catastrophic internal delamination—the “popcorn” effect. Our process begins with strict adherence to J-STD-033 standards, including baking components in calibrated ovens to safely remove all moisture. This neutralizes the risk before work even begins.

Precision De-balling and Site Preparation

Removing old solder balls without damaging the component’s sensitive pads is critical. We use carefully developed thermal profiles and specialized tooling to ensure the original spheres are removed cleanly. Afterward, the pads are prepared using a process that removes residual solder and re-establishes a perfectly planar, solderable surface, ready for the new alloy.

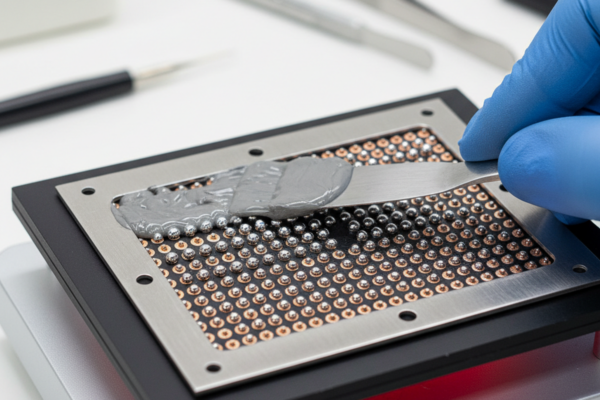

Controlled Flux Application and Sphere Placement

The type, volume, and application method of flux are critical. Too little results in poor wetting; too much can lead to residue entrapment and reliability issues. We use a controlled application process, followed by high-precision automated or semi-automated systems that place a single, perfect SAC305 sphere onto each pad.

The Reflow Profile: A Separate Science

Attaching the new spheres is not a standard reflow process. The thermal profile must be developed specifically for the component’s mass, package type, and substrate. The goal is to create a perfect metallurgical bond between the new sphere and the pad without overheating the component’s die. This requires a deep understanding of thermal dynamics and dedicated equipment separate from a standard production line.

Validation and Assurance: The Definition of a Successful Conversion

A successful conversion is not complete until it is proven. Our process integrates multiple inspection and quality gates to give you a part you can trust as much as an original.

Ionic Cleanliness and Post-Process Inspection

After reflow, components undergo a rigorous cleaning process to remove all flux residues. We verify the cleanliness to ionic standards, preventing any risk of electrochemical migration. This is followed by a detailed automated optical inspection (AOI) to confirm ball alignment, uniformity, and the absence of surface-level defects.

Sphere Lot Traceability for Process Control

Quality is not accidental. We maintain full traceability of the solder spheres used for every job. By linking a production run to a specific manufacturer lot, we ensure absolute process control and can trace any potential issue to its source—a level of control essential for professional manufacturing.

X-Ray Inspection Criteria that Reject Marginal Joints

The most critical validation is 2D/3D X-ray inspection, which allows us to see inside the solder joint. Our acceptance criteria are stringent. We don’t just look for bridges or voids; we analyze ball diameter, roundness, and placement uniformity across the entire package. We reject any component showing signs of a marginal process, ensuring only perfect parts re-enter your supply chain.

The Strategic Decision: In-House vs. a Specialized Partner

The complexity of a reliable reballing process naturally raises the question of bringing it in-house. A realistic assessment, however, reveals a high barrier to entry. It requires significant capital investment in dedicated equipment for de-balling, placement, reflow, and X-ray inspection. It demands skilled operators and engineers to develop and control the myriad sensitive processes. The risk of an uncontrolled in-house process is the very same field failure you sought to avoid. Partnering with a specialist like Bester PCBA means you aren’t just buying a service; you are leveraging a proven, de-risked engineering system. You gain immediate access to the equipment, expertise, and quality assurance of a mature process, turning a high-risk problem into a managed, reliable solution.