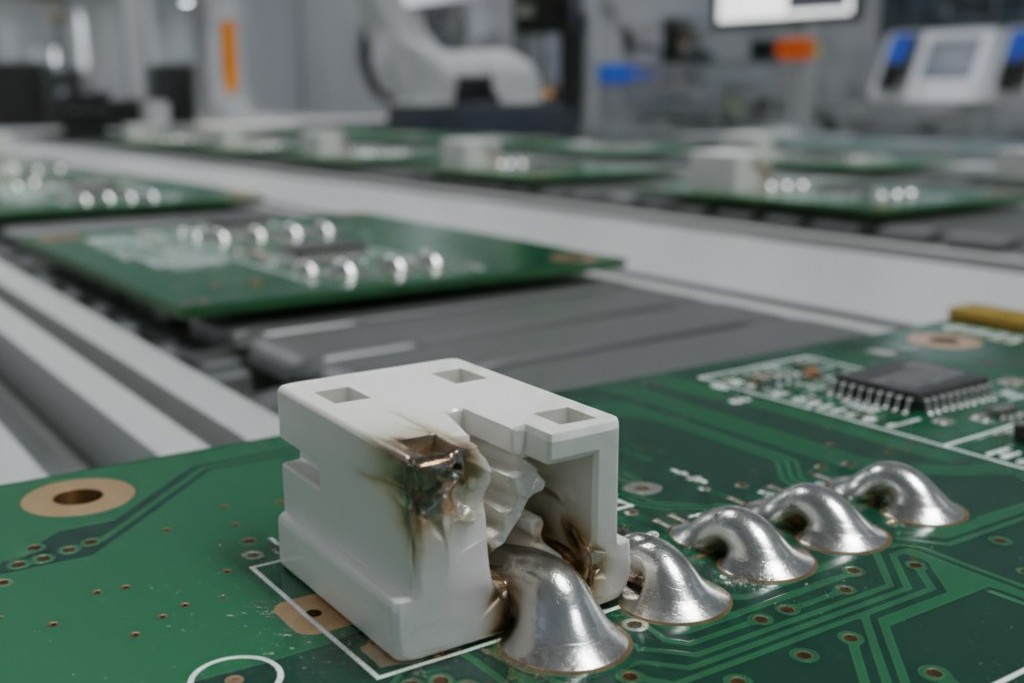

That expensive, perfectly good standoff connector is now scrap. Its plastic housing is scorched and warped, melted by a selective solder wave that passed just millimeters away. Elsewhere on the same board, a tight-pitch connector shows a mess of solder bridges—the result of the board sagging in a generic, ill-fitting pallet. This is a scene of quiet frustration, familiar to any engineer pushing the boundaries of board density.

At Bester PCBA, we see this not as a process failure, but as a tooling failure. The root cause is a reliance on one-size-fits-all pallets for assemblies that are anything but generic. The solution is to treat the pallet as what it truly is: a piece of custom process-control hardware.

The Inevitable Failure of One-Size-Fits-All

A generic selective solder pallet has a fundamental flaw: it tries to solve two opposing problems with a single, simple cutout. It must expose the solder leads to the fountain while simultaneously shielding everything else. When a tall plastic component sits right next to the solder joint, this compromise fails.

First comes the heat. A wave of molten solder at 280°C is a powerful source of radiated thermal energy, and a simple opening in a pallet offers no protection. An adjacent plastic housing absorbs this energy, exceeds its glass transition temperature, and begins to warp, discolor, or even melt. The solder joint may be perfect, but the component is destroyed.

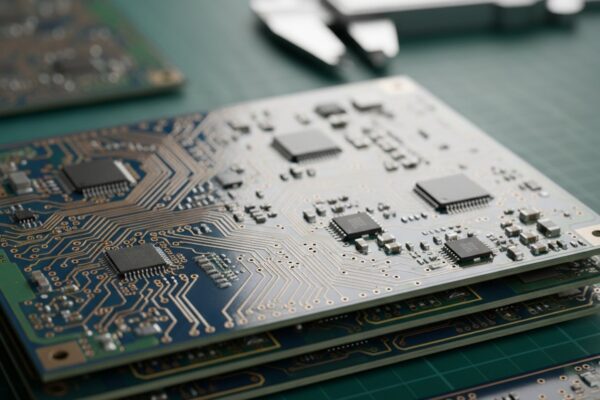

Heat also introduces a physical problem: sag. Generic pallets provide inadequate support around large openings, allowing the PCB to droop under its own weight when heated. For nearby fine-pitch components, this minute change in flatness is all it takes to cause inconsistent contact with the solder wave. The direct result is solder bridging and costly rework.

Sculpting the Pallet for Thermal Control

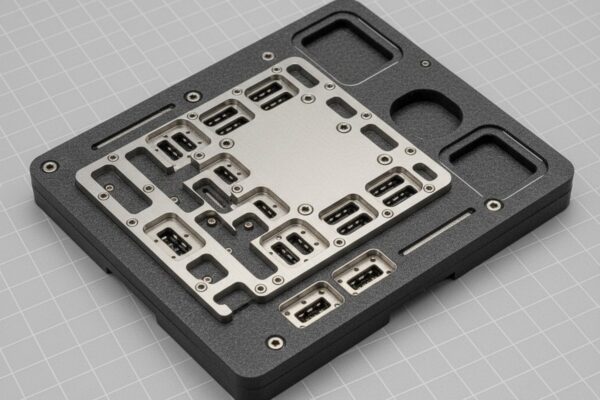

Our approach treats the pallet as the first line of defense against this thermal chaos. We don’t just cut openings; we sculpt the material to actively manage and direct heat, transforming a passive holder into an active thermal tool.

To prevent scorching on tall connectors, the most effective solution is a physical barrier. We machine “dams”—walls that rise up from the pallet material, sitting between the solder fountain and the sensitive component. They act like a shadow, physically blocking the line-of-sight radiant heat that would otherwise cook the plastic. For extremely sensitive areas, we engineer recessed pockets that sink the component below the primary heat path, adding another layer of protection.

The pallet material itself, a high-temperature composite, is an excellent insulator. We use this to our advantage. To protect a component, we leave more material in place, creating a block of thermal mass that absorbs and dissipates stray heat. Conversely, right at the solder joint, we relieve the pallet to minimize contact. This prevents the pallet from acting as a heat sink, ensuring all the fountain’s energy is used efficiently to create a fast, complete joint, not wasted heating the tool itself.

The Differentiator: Tuning with Live Data

But even the most perfectly sculpted pallet is just a static tool. True process control comes from pairing it with a dynamic, data-driven soldering program and abandoning the guesswork that plagues so many production lines.

The Myth of the “Golden” Dwell Time

Many operations rely on a “golden” dwell time—a universal setting of, say, three or four seconds applied to every job. This is superstition, not engineering. A fixed dwell time is either too long, risking thermal damage and wasting cycle time, or too short, resulting in incomplete wetting and a poor solder joint. It cannot possibly account for the unique thermal characteristics of each board, component, and pallet combination.

Our Method: Probing the Joint for Truth

We determine the correct dwell time by measuring it. Before a production run, we instrument a test board with thermocouples placed directly on the critical solder joints. We run this board through the selective solder machine with its custom pallet, monitoring the temperature profile at the joint. This data shows us exactly how long it takes to reach liquidus and achieve full, proper wetting on the pin and pad.

Our goal is to find the precise moment a perfect joint is formed, and not a fraction of a second more. We trim the dwell time based on this live data. Trying to eyeball this is professional negligence on a complex board; the data from the profiler is the only source of truth.

The Result: Honest Cycle Times, Zero Defects

Is this data-driven approach slow? On the contrary. By eliminating the buffer time and uncertainty of a “superstitious” dwell time, we arrive at the shortest possible duration that guarantees a perfect result. The process isn’t just reliable; it’s maximally efficient.

The outcome is a stable, predictable manufacturing process. Solder bridges and scorched components vanish from the defect logs. Rework costs plummet. Most importantly, cycle times become honest and dependable, allowing for accurate production planning.

It transforms a high-risk process into a routine, controlled operation.

A Process, Not Just a Part

A selective solder pallet for a complex assembly is not a commodity. It is the physical embodiment of a deeply understood and finely tuned process. The intelligence isn’t in the pallet’s CAD file, but in the methodology used to design it, test it, and pair it with a data-driven soldering program. By treating the pallet and process as a single, integrated system, we manufacture challenging designs with the same quality and predictability as the simplest boards.