[ARTICLE]

An SMT assembly line is a symphony of precision. Robots place components with breathtaking accuracy, solder paste is applied in moments, and boards flow through reflow ovens in a continuous, optimized rhythm. Then, the music stops. The entire line grinds to a halt, often because of a single, seemingly innocuous step: on-line programming.

Loading firmware onto a microcontroller while the board is still on the main assembly line is a silent killer of throughput. It seems convenient, but it introduces a vulnerability that ripples through the entire manufacturing process. At Bester PCBA, we know there’s a better way. It’s an approach that protects the rhythm of your production line by treating firmware loading with the strategic importance it deserves.

The SMT Line’s Golden Rule: Never Stop Moving

The efficiency of a surface-mount technology line is governed by a single principle: continuous flow. Every station, from paste printing to automated optical inspection, is timed to the second. This cadence, or takt time, dictates the maximum output of the entire factory. Any process that takes longer than this rhythm becomes an instant bottleneck, forcing every other station to sit idle.

On-line programming is the classic example. Flashing complex firmware can take anywhere from 30 seconds to several minutes. During that time, a multi-million dollar assembly line is held hostage by a single programming operation. The math is brutal. A 60-second programming time on a line with a 30-second takt time effectively cuts your potential throughput in half.

It’s a false economy.

The Strategic Shift: Decoupling Programming from Assembly

Our philosophy is simple: decouple programming from assembly. Treat firmware as a distinct, highly optimized manufacturing step, and you refuse to let the slowest operation dictate the factory’s pace. This strategic shift allows the SMT line to run at its maximum possible speed, focused exclusively on what it does best—assembling hardware. The programming happens in parallel, using specialized equipment designed for speed and reliability, and the main flow is never interrupted. The line keeps moving.

The Playbook: Two Methods to Reclaim Your Throughput

Once programming is decoupled from the main line, two powerful methods become available. The choice between them depends on product architecture, volume, and firmware complexity, but both are vastly superior to the on-line approach.

Method 1: Off-Line Gang Programming for Mass Parallelism

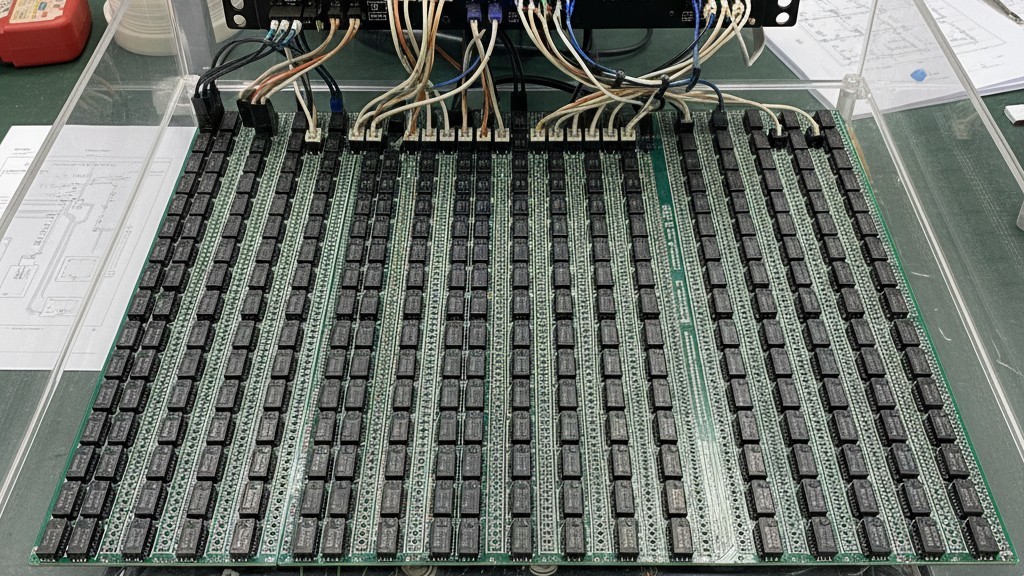

For high-volume production, the most efficient method is to program components before they are ever placed on the circuit board. With off-line gang programming, hundreds or even thousands of microcontrollers or flash memory chips are placed in a single fixture and programmed simultaneously. These pre-programmed components are then fed into the SMT line just like any other resistor or capacitor.

The result is true parallelism. The programming of an entire reel of chips can happen concurrently with the assembly of a different production run, completely removing that time from the critical path of any single PCBA. For products with stable firmware and a design that allows for pre-programming, this is the gold standard.

Method 2: High-Speed In-Circuit Flashing for Post-Assembly Speed

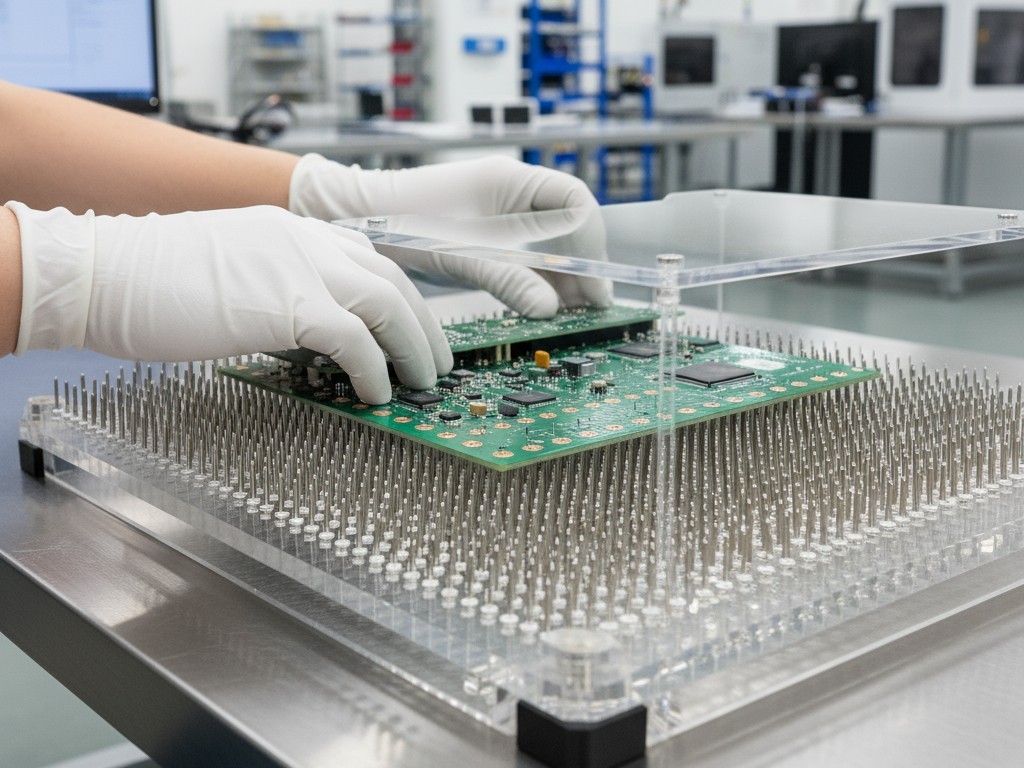

For products where firmware must be loaded after the board is fully assembled, the solution isn’t to stop the line. It’s to create a dedicated, high-speed flashing station. This is typically done after the SMT and reflow process is complete, often integrated with In-Circuit Test (ICT) or functional test fixtures.

Using a “bed-of-nails” pogo-pin fixture or a high-density, quick-connect cable, we can interface with the PCBA and load firmware at maximum bus speeds. Because this happens away from the SMT line, multiple boards can be programmed in parallel on a custom fixture. This station is engineered for one purpose: flashing firmware as fast as the hardware allows, often in a fraction of the time an on-line station would take.

The Traceability Question: Injecting Serials and Keys Without a Bottleneck

The most common objection to decoupling is traceability. “How,” clients ask, “can we inject a unique serial number or encryption key into each device if we are programming a thousand at once?” The answer is seamless integration between the programming station and the Manufacturing Execution System (MES).

The MES is the digital brain of the factory floor, managing all process data. In a decoupled workflow, the programming station—whether an off-line gang programmer or a post-assembly test fixture—requests a block of unique data from the MES. The MES assigns a set of serial numbers or keys and logs which identifier is being sent to which physical socket in the programming fixture.

After the flash is complete, the programmer reports the success or failure of each unit back to the MES. The system now has a perfect record of which unique device ID is associated with which PCBA, maintaining end-to-end traceability without ever slowing the line.

Designing for Speed: The Hardware Imperatives for Efficient Programming

A high-throughput programming strategy begins at the design stage. The hardware itself must be architected for speed and reliability.

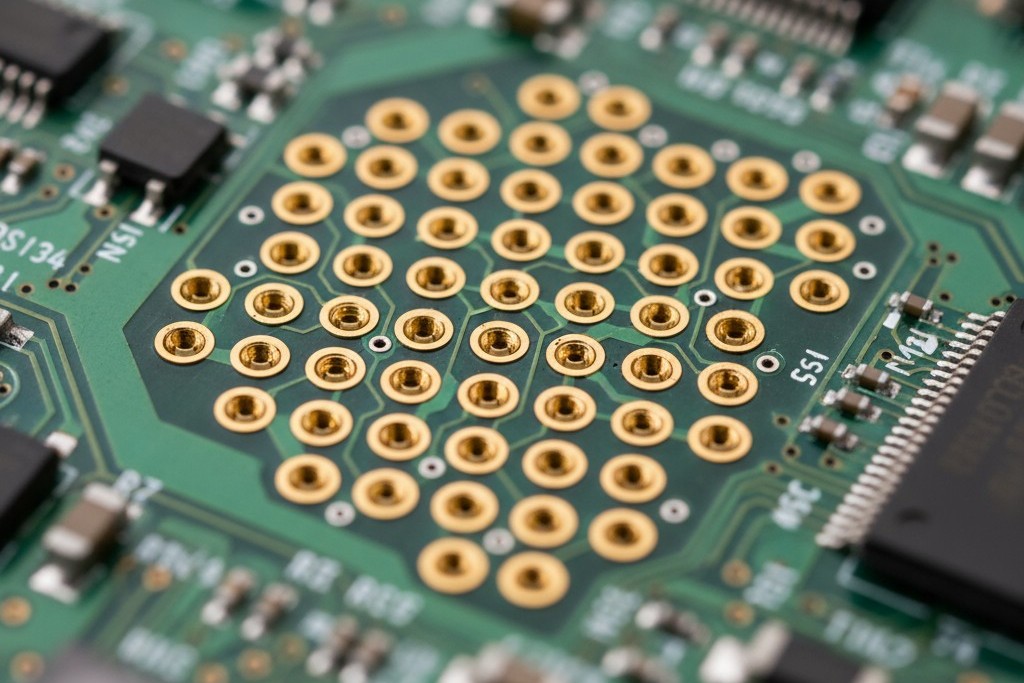

Expose the Right Interfaces: From Headers to Bed-of-Nails Pads

To achieve maximum flashing speed, the programming interface must be robust. A simple debug header is sufficient for development but inadequate for production. For high-speed in-circuit flashing, we recommend designing dedicated test pads on the bottom of the PCBA. These pads allow a bed-of-nails fixture to make a solid, reliable connection to the programming bus, enabling parallel data lines and higher clock speeds. If space is a concern, a small-footprint tag-connect interface is a far better choice than no interface at all.

The Critical Role of Power Sequencing

High-speed programming pushes a chip to its limits, and an unstable power supply during this process is a primary cause of bricked devices. Supplying the correct voltage isn’t enough; the power must be sequenced correctly. The core voltage rail must be stable before the programming clock starts, and the reset line must be handled with precision. A well-designed PCBA includes circuitry to ensure this power-on sequence is reliable every time—a small investment that prevents costly failures in mass production.

The Bester PCBA Verdict: A Process Built for Flow

The perceived convenience of on-line programming is a false economy, completely overshadowed by the massive opportunity cost of an idle production line. It is a strategy that prioritizes a single step over the health of the entire system.

At Bester PCBA, we build our processes around the principle of uninterrupted flow. By decoupling firmware loading and using high-parallelism methods like off-line gang programming or dedicated high-speed flashing stations, we protect our clients’ throughput and preserve the rhythm of the line. This approach not only moves products faster but also enhances traceability and provides the flexibility to manage complex firmware without compromise. The line keeps moving, and your product gets to market faster. [/ARTICLE]