If you’ve ever received a Printed Circuit Board Assembly (PCBA) quote with a single lump sum for “assembly services” or vague “miscellaneous charges,” you know the problem. For simple boards, this might be tolerable. For complex assemblies with high component counts, tight tolerances, or novel designs, opaque pricing is a significant risk. It cripples budgeting, obscures the link between design choices and cost, and creates an adversarial relationship where every unforeseen charge feels like a surprise fee.

At Bester PCBA, we reject this practice. Transparent pricing isn’t a courtesy; it’s a structural requirement for trust and accountability when realizing your engineering work. Our methodology is built on three pillars: time-driven quoting, explicitly disclosed risk buffers, and validation against actual production data. This approach creates more honest pricing than traditional fixed bids, and it provides a framework you can use to evaluate any PCBA provider’s quote.

By the end of this article, you will understand not just how we price complex assemblies, but why our approach reduces your risk. You will also have the tools to audit the pricing practices of any manufacturer, ensuring the quotes you compare reflect reality—not optimistic guesses or hidden margins.

Why Opaque Quotes Fail Complex Assemblies

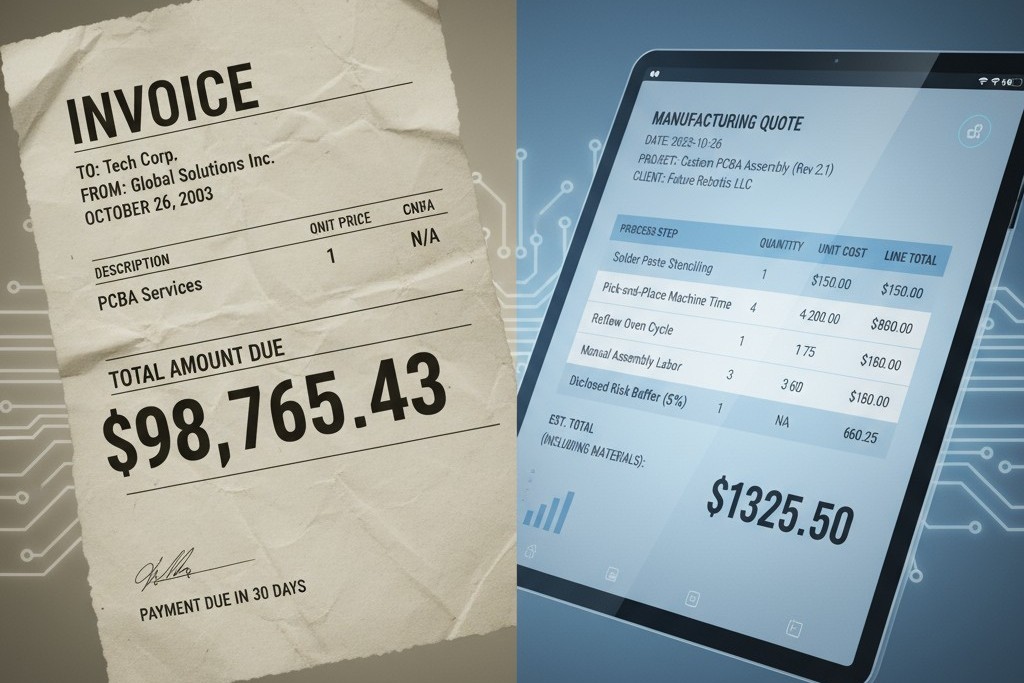

Opaque pricing is predictable. A quote might show a total for “PCB assembly” without breaking down machine time, labor, or material handling. It might add a percentage for “complexity” without defining the term or showing the math. It might offer a fixed price without disclosing the assumptions about yield, rework rates, or process variability that underpin it.

For assemblies involving hundreds of unique components or micro-scale soldering, these omissions are not minor. They represent a structural information asymmetry: the manufacturer knows the cost drivers, and the buyer does not. This asymmetry creates two failure modes.

The first is underquoting. To win the business, a manufacturer offers a low price based on optimistic assumptions. When production proves more difficult, they must either cut corners on quality or return with change orders and cost increases. The former introduces hidden quality risk; the latter erodes trust.

The second is overquoting. A risk-averse manufacturer embeds substantial hidden padding into the price to guard against worst-case scenarios. The buyer pays for uncertainty that may never materialize. Because the padding is undisclosed, there’s no mechanism to refund the difference if the production run goes smoothly. The manufacturer profits from withheld information.

Complexity amplifies both failures. An assembly is complex when factors increase process variability. High component density raises the likelihood of solder bridging. Tight placement tolerances reduce the margin for error. Non-standard components demand custom process parameters. Each factor introduces variables that a lump-sum price must either ignore, guess at, or pad against.

When a quote hides these variables, you lose the ability to evaluate if the price is rational. You cannot tell if a high quote reflects genuine complexity or excessive padding. You cannot compare quotes from multiple vendors on equivalent terms. Most critically, you have no way to hold the manufacturer accountable, because the quote never specified what work was being priced.

Time: The Foundation of Honest Pricing

The most reliable unit for pricing manufacturing is time. The cost of transforming components into a functional assembly is determined almost entirely by the duration of machine operation and skilled labor required. Material costs are straightforward and verifiable. Time is the variable that introduces risk.

Time is measurable, recordable, and auditable. A cycle time for a reflow oven or a duration for manual inspection is a fact that can be verified against production logs. Time is also comparable. If one provider quotes 30 labor hours for a task and another quotes 50, the difference demands inquiry. A lump-sum price offers no such clarity.

When pricing is tied to time, you gain visibility into what drives cost. When it’s tied to a fixed sum derived from undisclosed assumptions, you are asked to trust without verification. For complex assemblies, this is the difference between a quote that reflects analysis and one that reflects guesswork.

How Time-Driven Quoting Works at Bester

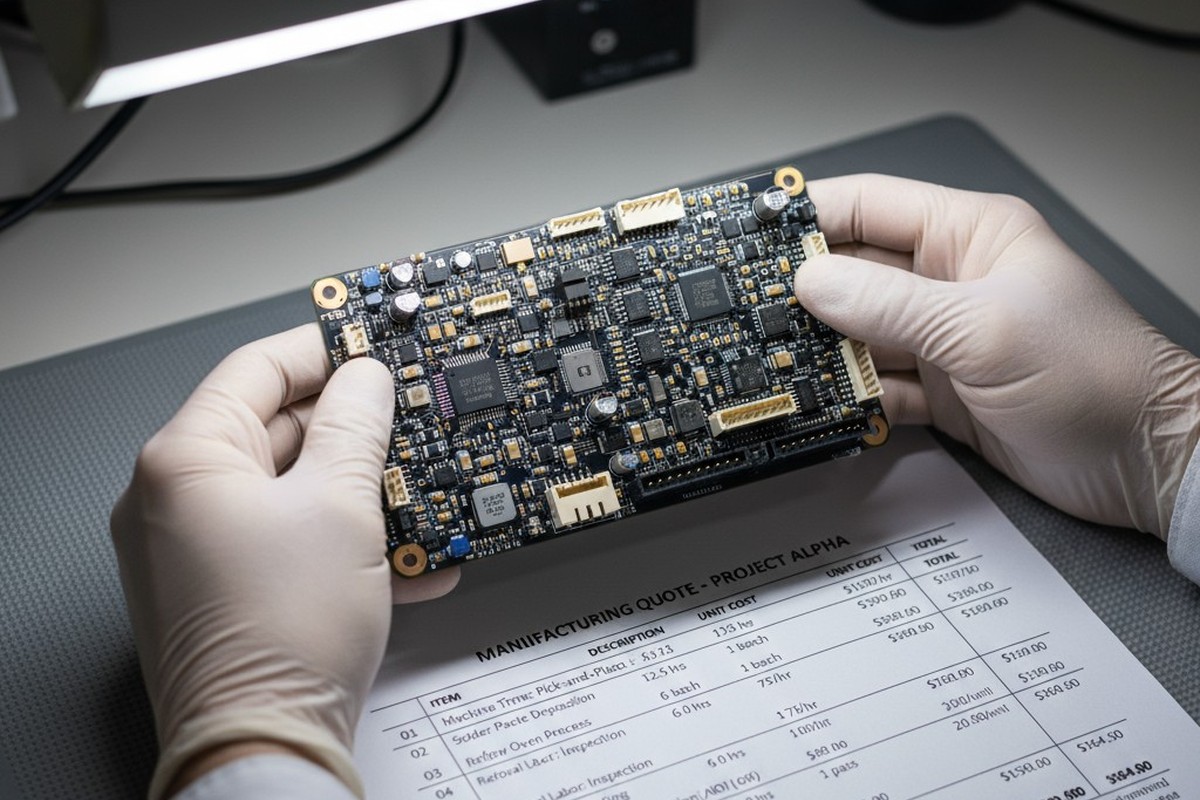

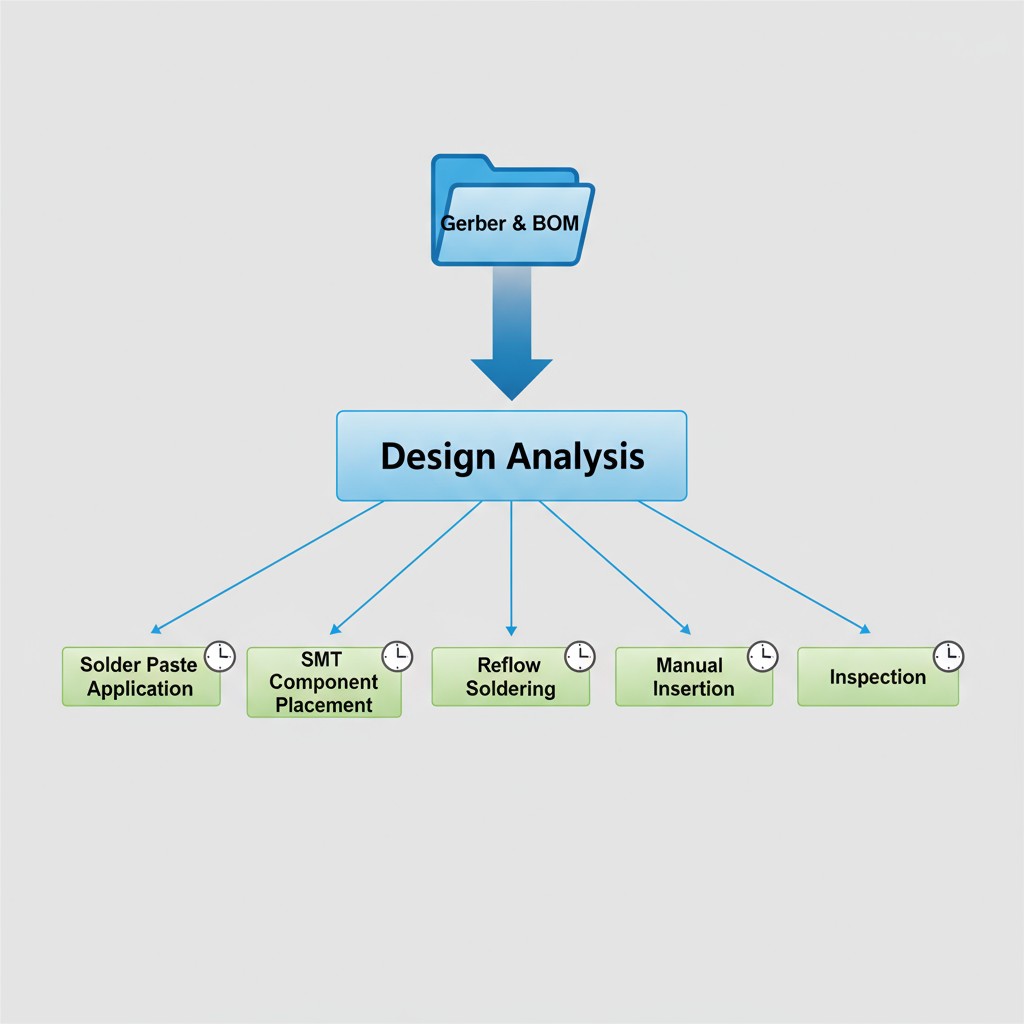

Our quoting process begins with a detailed analysis of your design files, including the bill of materials, Gerbers, and any assembly drawings. We break the work into discrete, time-estimated tasks: solder paste application, pick-and-place component placement, reflow soldering, manual component insertion, inspection, and testing.

For machine operations, time estimates are derived from known cycle rates, adjusted for design specifics. A board with 200 components requires more pick-and-place time than one with 50, but the relationship isn’t linear; placement order, component size, and type all affect speed. We calculate the expected cycle time and apply our machine hourly rate, which covers equipment amortization, maintenance, and operator oversight.

For labor operations, estimates are based on historical data and engineering judgment. Manual insertion of a connector has a predictable duration. Inspecting fine-pitch components under a microscope takes longer than inspecting standard ones. We document each estimate in the quote with the associated labor rate, reflecting the skill level required.

Material handling, kit preparation, and setup time for tooling are also included as line items. These are real costs, particularly for low-volume runs where setup time isn’t amortized across thousands of units, yet they are often buried in lump-sum quotes. The result is a quote specifying not just the total cost, but the work being purchased.

What This Means for Your Quote

A time-driven quote provides predictability. If a design change increases the component count by 20 percent, you can anticipate a proportional increase in pick-and-place time and calculate the cost impact before committing. It also provides a clear basis for comparing vendors. A significant difference in estimated time for the same operation signals a difference in process efficiency or interpretation of the design, inviting clarifying questions rather than a blind choice.

Most importantly, it establishes a measurable standard for accountability. If the quoted time was based on explicit assumptions and production data shows a variance, both parties have a common reference point for understanding why. The quote becomes a record of shared expectations.

Disclosed Risk Buffers vs. Hidden Padding

Even with precise time estimates, complex assemblies introduce uncertainty. A component with a tight thermal window might require reflow profile adjustments. A dense layout might carry a higher risk of solder defects. These uncertainties manifest as rework time, yield loss, or delays.

In traditional fixed-bid pricing, manufacturers account for this risk with hidden padding—an undisclosed margin to cover potential rework. The buyer pays for this buffer but has no visibility into its size or justification.

We disclose risk buffers as explicit line items. This doesn’t eliminate uncertainty; it makes it transparent.

Calculating and Disclosing Risk

Our buffer estimate begins with assessing the design’s risk profile. We evaluate factors correlated with rework, such as component density, pitch, and the number of unique parts. Components with non-standard pad geometries or those requiring manual intervention carry higher per-unit risk. We also consider process novelty. If an assembly requires a process parameter set we haven’t used before, the risk increases.

The buffer is expressed as additional time for potential rework, calculated as a percentage of the base process time or as a fixed allocation. For example, an assembly with 150 fine-pitch components might include a buffer for statistical rework based on historical defect rates. The quote will disclose this buffer with a rationale: “This time is allocated to address potential solder joint defects given the component density.”

This approach differs fundamentally from padding. A disclosed buffer is visible and tied to identifiable risk factors. If the risk doesn’t materialize, the time isn’t consumed, and the final bill reflects actual work performed, not worst-case assumptions. The fixed-bid alternative forces you to overpay when production goes smoothly, with no recourse to recover the difference.

Holding Pricing Accountable with Production Data

A transparent quote is credible only if it is paired with accountable billing. A time-driven quote is valuable only if the actual time consumed is tracked, compared to the estimate, and used to inform the final cost. We close this loop by collecting detailed production data for every assembly run.

The Data We Track

Our production lines are instrumented to capture time-stamped data. Pick-and-place machines log cycle times, reflow ovens record profiles, and inspection stations log time per board and defects found. Manual operations are tracked through work orders. This data provides the factual record of how much time was required to complete the quoted work.

We track rework separately. If a board requires extra work due to a design characteristic we anticipated in the risk buffer, the time consumed validates the buffer. If the rework was caused by our own process error, it is flagged as an internal issue and does not affect your bill. Yield data—the number of boards passing on the first attempt—provides an empirical measure of manufacturability and helps us refine future estimates.

Resolving Discrepancies

At the end of a run, we compare the actual time logged against the quote. For new or complex designs, variances provide learning data. If actual time significantly exceeds the quote, we investigate the cause. Was it an incorrect assumption about the design? An unforeseen issue with a supplier’s component? An inefficiency in our own operation?

When a variance is design-related and exceeds the disclosed buffer, we communicate the finding to you with supporting data. This is a shared learning opportunity that helps refine future estimates. When a variance is our responsibility, we absorb the cost. The quote is our commitment. This discipline ensures our quoting rigor remains high, as our incentive is to quote accurately and execute efficiently.

How to Evaluate Any PCBA Quote for Transparency

You can and should use these principles to evaluate any provider’s quote. A transparent quote has specific characteristics; an opaque one should raise questions.

Look for granularity. A transparent quote breaks down costs into identifiable categories tied to measurable work: machine time, labor time, setup. If you see a single line for “assembly services,” ask for a breakdown. A provider who has done the analysis can provide it.

Examine the basis for time estimates. Ask how labor or machine hours were derived. Are they based on historical data, standard cycle times, or engineering analysis? A provider using time-driven quoting will have a clear answer.

Identify disclosed buffers. If a quote includes extra cost for risk mitigation, it’s a positive sign. It shows the provider has analyzed the design for difficulties and is accounting for them openly. Ask what specific risks the buffer addresses.

Ask about data tracking and accountability. Will the provider compare actuals to estimates? Will you receive a report of cycle times, defect rates, and rework hours? A provider committed to accountability will have a process to capture and share this data.

Question quotes that seem too low or too high. A low quote may signal underestimation or corner-cutting. A high quote may reflect excessive padding or inefficiency. Without transparent line items, you can’t diagnose the cause. Insist on visibility.

For low-complexity projects with standard components and generous tolerances, a simplified quote may be acceptable. The principle remains the same: ensure the price reflects a rational analysis of the work, but the depth of documentation can scale with the design’s risk.

A transparent quote gives you the information to assess value, compare alternatives, and hold your partner accountable. An opaque quote asks for trust without verification. At Bester PCBA, we believe that trust must be earned through transparency, not assumed. Our commitment to time-driven quoting, disclosed buffers, and data accountability is how we earn it.