For any company bringing a physical product to life, the journey from design to a shipped device is fraught with critical decisions. Few are more consequential, or more misunderstood, than the choice of how to verify the integrity of a printed circuit board. This decision, often distilled to a contest between Flying Probe Testing (FPT) and In-Circuit Testing (ICT), is far more than a technical footnote. It is a strategic choice that directly shapes a company’s cash flow, its production velocity, and its very ability to innovate.

While both methods exist to find the manufacturing flaws that can render a board useless, they represent two fundamentally different philosophies of production. One is an act of dynamic inquiry, the other a statement of mass production. To choose ICT too soon is to chain a young company to a fixed design with a heavy capital outlay. To rely on FPT for too long is to create a production bottleneck that can strangle growth just as it begins. The question is not which test is superior, but which aligns with the reality of a specific product at a specific moment in its lifecycle.

The Physicality of a Test

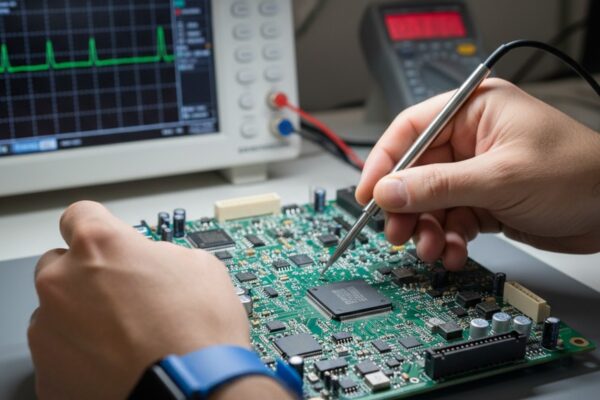

To understand the profound differences between these two approaches, one must first appreciate how they physically interact with a circuit board. The distinction is one of access, sequential versus parallel, and from this single difference, all other consequences of cost, speed, and flexibility flow.

Flying Probe Testing is an act of robotic precision. It operates like an automated multimeter, its two to six probes moving with incredible speed across the board’s surface. Guided by software derived from the board’s own design files, the probes land on component leads, vias, and test pads in a carefully choreographed sequence. By touching multiple points, the machine measures for the shorts, opens, and component values that signal a manufacturing error. The entire process is ephemeral, a conversation in software that requires no custom hardware.

In-Circuit Testing is, by contrast, an act of physical commitment. It relies on a custom-engineered fixture, a “bed of nails,” which is a clamshell device holding a dense array of spring-loaded pogo pins. These pins are arranged in a unique constellation, a mirror image of every test point on the board’s underside. When a board is pressed into the fixture, hundreds or thousands of connections are made at once. This parallel contact allows the system to test every net on the board in a single, rapid-fire sequence. The fixture itself, however, is a piece of immutable hardware, a physical snapshot of one specific board revision. Any change to the board’s layout that moves a test point renders this expensive tool obsolete. This makes ICT anathema to the iterative process of product development, where design evolution is not just expected but necessary for survival. For a product still in flux, the software-defined agility of FPT is the only tenable path.

The Economics of Commitment

The financial models of FPT and ICT are a direct reflection of their physical nature. The choice presents a classic trade-off between a significant upfront investment for low per-unit costs and zero initial investment for high per-unit costs. For a startup, this is not an accounting exercise; it is a statement of capital allocation strategy.

FPT is defined by its absence of Non-Recurring Engineering (NRE) costs. Because the test is born from software, testing can begin almost as soon as the first boards emerge from the assembly line, with no capital outlay for custom tooling. This immediacy is invaluable for prototypes and early production runs. The price of this flexibility is paid in time. The sequential nature of the test means each board takes longer to process, resulting in a higher cost for every unit tested.

ICT operates on the opposite economic principle. Its substantial NRE, which can range from a few thousand to tens of thousands of dollars, represents the cost of creating a precision tool. That investment is not arbitrary. It pays for the complex engineering to design the fixture, the precision drilling of a G10 plate, and the painstaking manual labor of installing and wiring hundreds or thousands of individual pogo pins to an interface. This high initial cost is then amortized over the production run. Once this investment is made, the test itself is exceptionally fast, often taking less than a minute, which drives the per-unit cost to mere pennies. The model is brutally efficient for mass production, but its initial barrier can be prohibitive for a company that needs to conserve capital.

The Cadence of Production

The timeline of testing unfolds in two distinct phases: the time to the very first test, and the time per test thereafter. FPT offers immediacy. ICT promises throughput. A production manager must decide which of these is more valuable at a given moment.

The “time to first test” for ICT is measured in weeks. The design, fabrication, and validation of a custom fixture is a significant project in its own right, creating a substantial lag between when boards are built and when they can be fully verified. For a new product launch with tight deadlines, this delay can be untenable. A flying probe program, in contrast, can be generated from CAD data in a matter of hours. This allows testing to begin the same day boards come off the line, providing immediate feedback to the engineering and production teams.

Once operational, however, the roles reverse dramatically. An ICT system’s ability to test a board in under a minute makes it a powerhouse of efficiency. It keeps pace with high-speed assembly lines, ensuring that testing never becomes the bottleneck. This is where FPT begins to show its limitations. As production volumes climb into the thousands, the minutes-per-board test time of a flying prober can create a significant logjam, slowing shipments and frustrating customers.

The Search for Certainty

While both methods are remarkably effective, often catching over 95% of common manufacturing faults, they perceive flaws in slightly different ways. They are both looking for shorts between traces, open circuits, and incorrect or missing components, and for most digital boards, the difference in coverage for these critical defects is negligible.

Yet, nuances exist. Because an ICT fixture can be designed to electrically isolate components from the surrounding circuitry, it generally has an edge in the precise measurement of analog values. It can more reliably confirm that a resistor or capacitor is within its specified tolerance. A flying prober, while capable of these same measurements, can sometimes struggle to achieve the same level of precision on a dense, complex board. Conversely, the FPT’s method of testing net by net makes it exceptionally adept at detecting physical open circuits, as it is a direct verification of electrical continuity from one point to another.

A Framework for a Strategic Choice

The decision, then, transcends a simple technical comparison. It becomes a strategic calculation of cost, volume, and risk. The logic can be quantified by finding the break-even point, that volume of production where the high per-unit cost of FPT equals the total cost of ICT with its large initial fixture investment. This point of inflection, often falling between 500 and 2,000 units, is where the financial logic begins to shift.

However, this calculation is not an absolute rule. For a Class III medical device or a critical aerospace component, the cost of a single field failure is so immense that the ICT fixture’s NRE is simply a non-negotiable part of ensuring quality, regardless of volume.

For most growing companies, the most sophisticated strategy is one that embraces both methods in sequence. It begins with designing the board for ICT from the very first revision, including a full set of test pads even if they will initially lie dormant. This act of foresight, a core tenet of Design for Test (DfT), costs little at the design stage but pays enormous dividends later. Production can then begin with FPT, leveraging its zero-NRE advantage to validate the design and test the market without a large capital risk. When market demand is proven and production scales to a point where FPT becomes a bottleneck, the company can confidently invest in an ICT fixture, knowing the board is already prepared for a seamless transition to high-speed testing.

Ultimately, the greatest risk is not in choosing the “wrong” test method. The real danger comes from skipping robust electrical testing entirely, or from choosing a method that creates a crippling business risk. Selecting ICT too early wastes precious capital. Sticking with FPT too long stalls a company’s growth. The correct choice is the one that aligns the physical reality of the factory floor with the financial and strategic reality of the business itself.