In the brutal environment of a modern vehicle, where electronics endure a life of violent temperature swings and constant vibration, the solder joint is the point of greatest faith. It is a microscopic metallic bond, unseen and unthought of by the driver, yet it is what holds the digital intelligence of the car together. For decades, that faith was placed in traditional tin-lead solder, a remarkably forgiving and ductile material. But a global regulatory push, driven by environmental concerns, has forced the automotive industry into a complex relationship with its lead-free successors.

This is not a simple story of material substitution. The transition from leaded to lead-free solder represents a fundamental shift in the physics of manufacturing and the philosophy of long-term reliability. The question is no longer if the industry will move, as narrowing exemptions for safety-critical systems make the lead-free future an inevitability. The real question, the one engineers grapple with on factory floors and in validation labs, is how to manage this transition without betraying the trust placed in every single electronic connection. It is a challenge that begins with the searing reality of higher heat.

A New Reality Forged in Higher Temperatures

The entire manufacturing process for a printed circuit board assembly is orchestrated around the melting point of its solder. Tin-lead solder offered a predictable target, becoming fully liquid at 183°C. Lead-free alloys, most commonly a mix of tin, silver, and copper known as SAC305, demand much more. They require peak reflow temperatures climbing toward 250°C, a significant thermal leap that sends shockwaves through the entire assembly line.

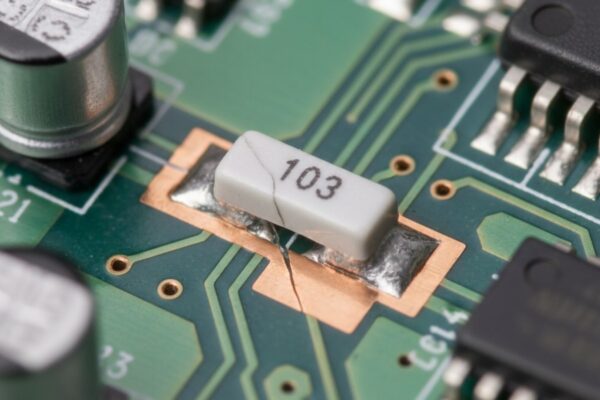

This elevated heat is not merely an adjustment to an oven’s thermostat. It is a new and aggressive stressor. It places immense strain on thermally sensitive components and can force a move to more expensive PCB substrates with a higher tolerance for heat, just to prevent the board itself from delaminating. The first shock for any seasoned inspector, however, is purely visual. Decades of training equate a bright, lustrous solder finish with a quality joint. Lead-free solder offers a dull, matte grey surface that looks, to the untrained eye, like a mistake. This aesthetic shift requires a complete cultural and technological reset, forcing the retraining of manual inspectors and the wholesale reprogramming of automated optical inspection systems that would otherwise see a perfectly good board as a field of failures.

This battle with heat extends to the very chemistry of the connection. Molten lead-free solder has a higher surface tension, a stubborn reluctance to flow and properly “wet” the copper pads it must bond with. This forces a two-pronged attack on the factory floor. First, a more aggressive chemical flux is needed within the solder paste to scrub the metal surfaces clean. Second, and often essential for high-yield production, is the introduction of a nitrogen atmosphere into the reflow oven. This expensive blanket of inert gas starves the process of the oxygen that would otherwise cause the solder to oxidize and fail to bond, a costly but necessary step to ensure a reliable connection.

The Physics of Failure: Ductility, Brittleness, and the Open Road

The true test of a solder joint happens not in the factory, but over a decade of life on the road. Here, the material differences between leaded and lead-free alloys become most apparent. Automotive electronics are in a constant state of thermal war, expanding and contracting with temperature swings from a -40°C winter start to a 125°C under-hood bake. Tin-lead solder, with its exceptional ductility, could absorb this stress. It would give and flex, accommodating the mismatched expansion rates between a tiny component and the larger circuit board.

Lead-free SAC alloys are different. They are mechanically harder, stiffer, and will deform less before they fracture. This relative “brittleness” is perhaps the most misunderstood aspect of the transition. It does not mean the joints are inherently weak. A well-designed lead-free joint possesses more than enough strength for automotive use. What it means is that the material’s forgiveness is gone. The stiffness transforms brittleness from a fatal flaw into a critical design consideration, demanding that engineers more deliberately manage mechanical stress through techniques like underfilling large components or adding mechanical supports.

This property becomes even more critical when considering vibration and shock. The ductility of leaded solder allowed it to absorb significant mechanical energy. A stiffer lead-free joint is more susceptible to fracturing under the high-g forces of a pothole or the sustained vibration from an engine. This reality complicates alloy selection. While the standard SAC305 alloy offers a good balance of properties, the high cost of silver has driven interest in low-silver alternatives like SAC105. While its thermal performance is often comparable, its ability to withstand shock is noticeably poorer. For a control unit nestled safely in a dashboard, this might be an acceptable cost-saving trade. For a sensor mounted to a chassis, it could be a critical point of failure.

Ghosts in the Machine and Long-Term Risks

Beyond the immediate challenges of heat and mechanics lie more subtle, long-term concerns. The early days of the lead-free transition were haunted by the specter of “tin whiskers,” tiny, electrically conductive filaments that could spontaneously grow from pure tin surfaces and create short circuits. While the phenomenon is real, the risk in modern automotive manufacturing is well-managed. The use of alloys instead of pure tin, improved component plating, and the near-universal application of a conformal coating to encapsulate the final board have rendered it a minimal threat.

A more insidious concern grows slowly from within the joint itself. At the interface where solder meets the copper pad, a new, brittle layer of an intermetallic compound, or IMC, is formed. This layer is essential for a strong bond, but in lead-free systems, it tends to be thicker and grows over the product’s lifetime, a process accelerated by high temperatures. What this means, in practical terms, is that a joint can slowly weaken from the inside out over a decade. For a vehicle designed to last fifteen years, this is not a theoretical problem. It is a ticking clock that must be accounted for in long-term reliability modeling.

The supply chain itself presents another risk. In a complex global network, ensuring every single component has a lead-free compatible termination is a monumental task. The accidental mixing of technologies on an assembly line, such as using leaded solder on a component with a bismuth-containing termination, can create a new alloy with a melting point as low as 96°C. Such a joint could fail during normal vehicle operation, a catastrophic outcome that can only be prevented by absolute process discipline and strict inventory control.

The Path Forward: A Mandate for Re-qualification

It should be clear that switching to lead-free solder is not a drop-in replacement. It is a fundamental re-engineering of the product at a material level. Simply swapping the solder alloy and assuming equivalent performance is a dangerous and misguided shortcut.

A robust validation plan is not just a final step; it is a mandatory requirement for market entry. This process must begin with the components themselves, verifying that each one can survive the higher reflow temperatures. It extends to the circuit board, ensuring its material can withstand the thermal stress without damage. Most critically, it culminates in the exhaustive testing of the final, complete assembly. The new lead-free product must be subjected to a full suite of accelerated life tests, from thermal shock to vibration and drop testing. The goal is to generate a robust dataset that proves, with empirical confidence, that the new assembly meets or exceeds the proven reliability of its leaded predecessor. Only then can the faith once placed in lead be confidently transferred to its modern successor.