The choice between underfill and corner-bond is one of the most consequential decisions in designing a robust printed circuit board assembly. It’s a classic engineering trade-off. There is no perfect answer, only a “lesser evil” for your specific application. On one hand, you have capillary underfill, a rigid epoxy that locks a component to the board like a fortress but turns any future service into destructive surgery. On the other, you have elastomeric corner-bond, a flexible adhesive that absorbs shock while keeping the door open for rework.

At Bester PCBA, we’ve navigated this decision with clients for years. The debate isn’t just about materials; it’s a strategic choice that affects your product’s entire lifecycle, from manufacturing complexity to field serviceability. While the allure of absolute rigidity is strong, our experience shows that it often comes at too high a price.

This is our framework for choosing the right reinforcement—a guide to help you avoid common pitfalls and find a solution that balances reliability with pragmatism.

The Unseen Enemy: How Vibration Cracks Solder Joints

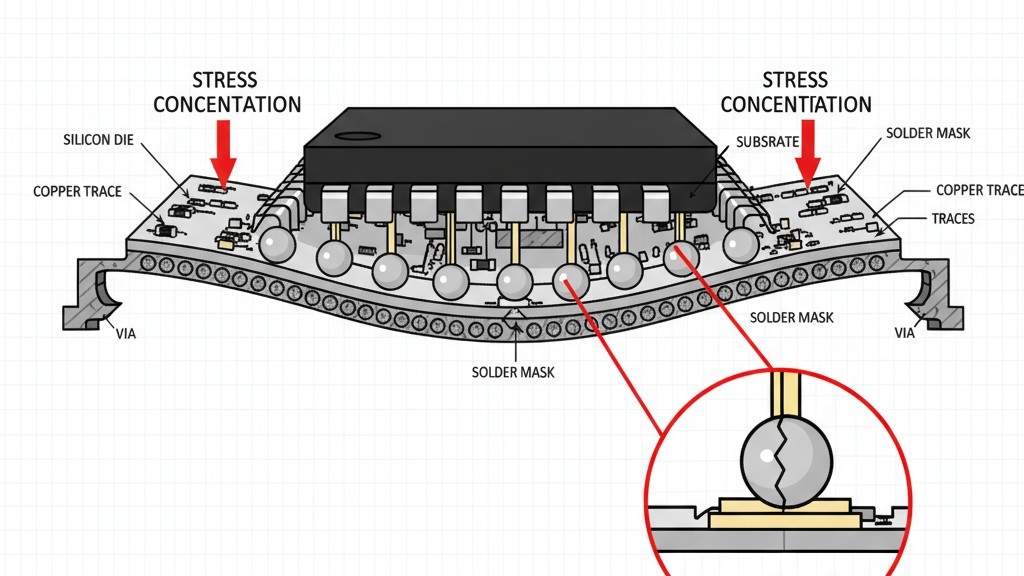

To choose a defense, you must first understand the attack. For a Ball Grid Array (BGA), vibration is a relentless, cyclical force. The problem isn’t the vibration itself, but the differential flexing it creates between the rigid BGA package and the more pliable circuit board. Imagine a stiff ceramic tile glued to a rubber mat that is being constantly warped. The stress doesn’t go into the tile or the mat; it concentrates entirely in the thin, brittle layer of glue connecting them.

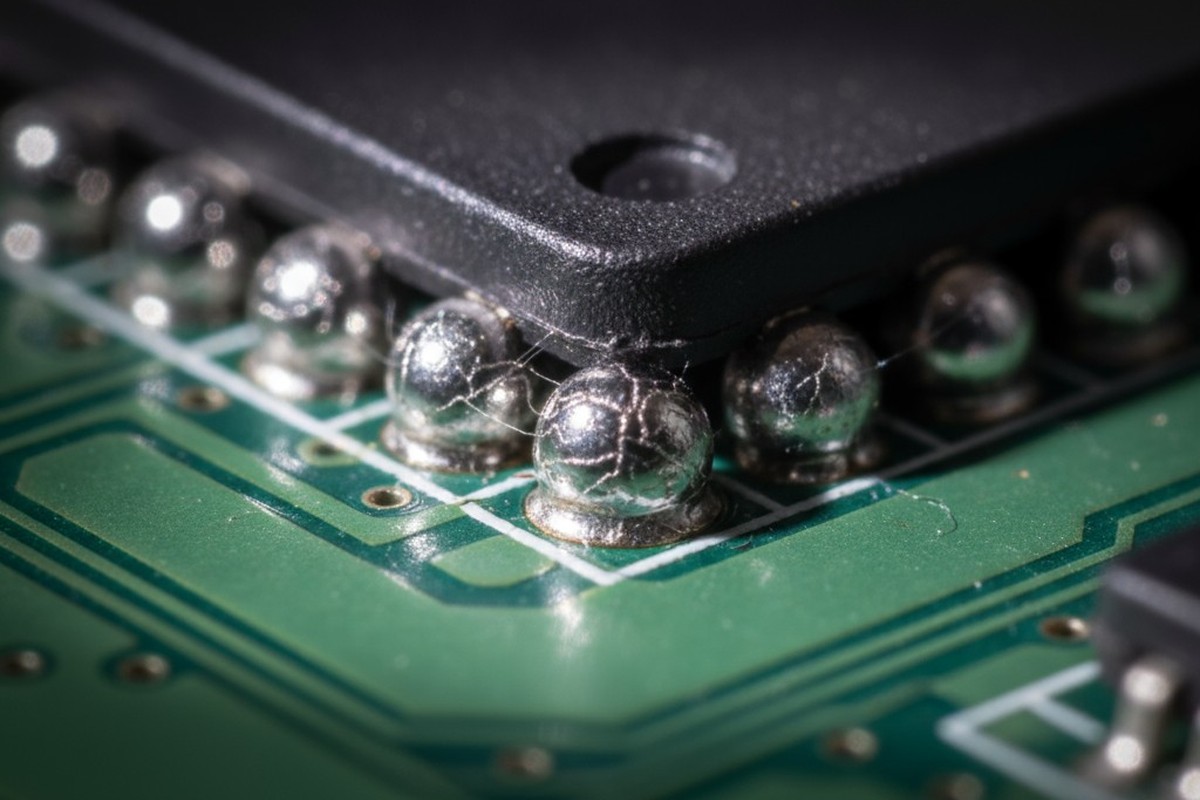

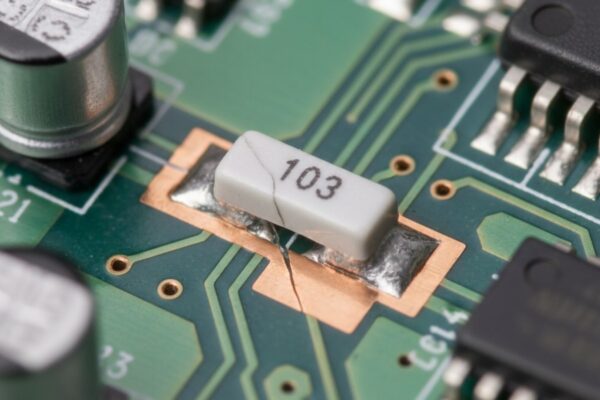

In a PCBA, the solder balls are that layer of glue. As the board flexes, the outermost solder joints endure immense tensile and shear stress, cycle after cycle. This leads to micro-cracks that propagate over time, eventually causing an open circuit and catastrophic failure. This is solder fatigue. It’s the primary failure mode that both underfill and corner-bond aim to prevent, albeit through entirely different philosophies.

The Rigid Fortress: Understanding Capillary Underfill

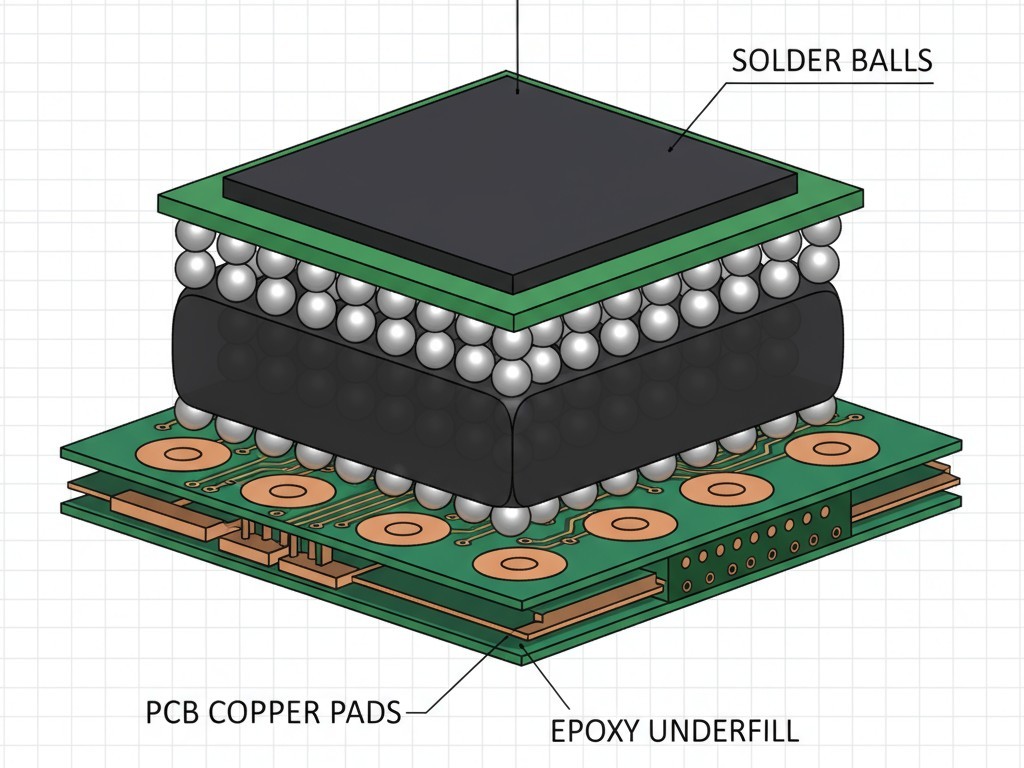

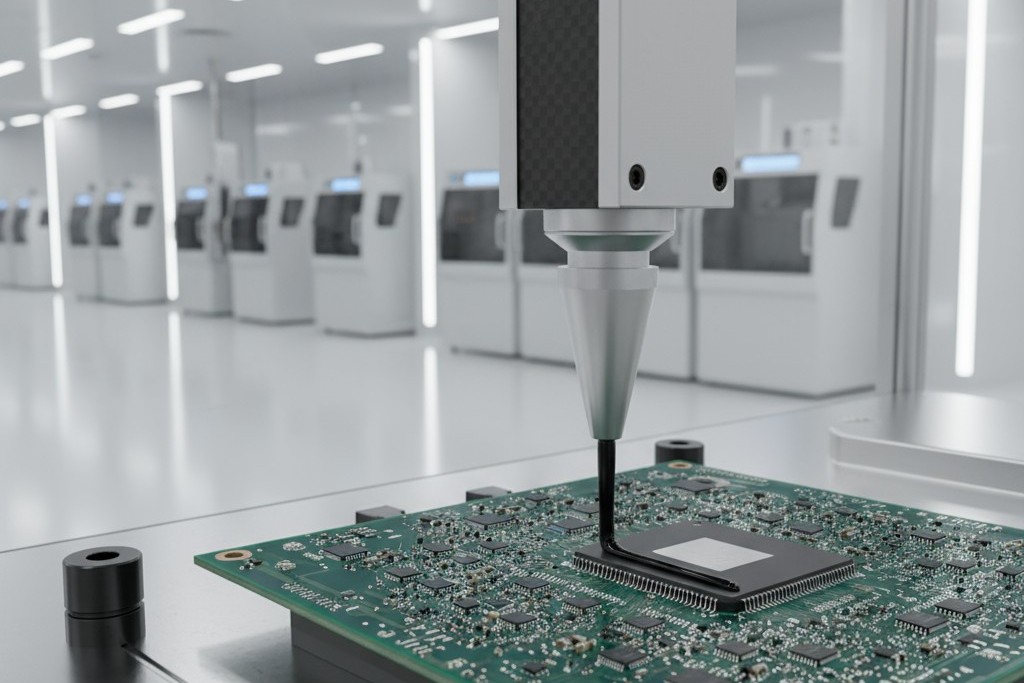

Capillary underfill is a low-viscosity epoxy applied along the edge of a BGA after it has been soldered. Through capillary action, the fluid is drawn underneath the entire component, filling the gap between the package and the PCB. Once cured, it forms a hard, continuous structural bond connecting the component body directly to the board surface.

How It Works: Creating a Solid, Monolithic Structure

The core principle of underfill is to eliminate differential flexing entirely. By creating a solid connection, it mechanically couples the BGA to the board, forcing them to move as a single, monolithic unit. This transfers stress away from the fragile solder balls and distributes it throughout the much larger surface area of the component and the underlying board laminate. For pure vibration resistance, this method creates an incredibly durable assembly, effectively making the BGA an integral part of the board itself.

The Hidden Cost: Rework Impossibility and Transferred Stress

This rigidity, however, is a double-edged sword. The first cost is serviceability. An underfilled component is permanent. Rework isn’t a delicate desoldering process; it’s a destructive act of prying and chipping that almost guarantees damage to the PCB pads. If that BGA fails, the entire board is often a write-off.

The more subtle cost is transferred stress from thermal cycling. The underfill epoxy, the BGA package, and the FR-4 board all have different Coefficients of Thermal Expansion (CTE). As the assembly heats and cools, they expand and contract at different rates. Because the rigid underfill locks them together, immense stress builds within the system. Instead of being absorbed, this stress is transferred directly into the BGA package and the PCB, potentially causing other failures like pad cratering or die cracking. Underfill solves the vibration problem by creating a thermal stress problem.

The Flexible Guardian: Understanding Elastomeric Corner-Bond

Corner-bonding, sometimes called edge-bonding, takes the opposite approach. Instead of a rigid, full-coverage epoxy, it involves applying beads of a flexible, elastomeric adhesive at the four corners of the BGA package. It does not flow underneath the component.

How It Works: Absorbing Energy at the Edges

Rather than creating a single rigid structure, corner-bond acts as a set of shock absorbers. The flexible material dampens vibration energy and controls the board’s flex relative to the component, but it does not eliminate it. It allows for a small amount of compliant movement, which is key to its effectiveness. By anchoring the corners, it significantly reduces stress on the outer rows of solder balls—the ones most vulnerable to fatigue—without creating the high-stress, monolithic block that underfill does.

The Pragmatic Advantage: Serviceability and Stress Relief

The greatest advantage of corner-bonding is pragmatism. Rework is simple and non-destructive. The corner bonds can be carefully cut, allowing the BGA to be desoldered, replaced, and re-bonded using standard processes. This preserves the value of the board and makes field service viable.

The elastomeric nature of the adhesive is also highly compliant during thermal cycling. Because it is flexible, it absorbs the differential expansion and contraction between the BGA and PCB, generating very little stress. It protects against vibration without introducing the thermal-mechanical risks associated with rigid underfill. It solves the primary problem without creating a secondary one.

The Deciding Factor: Our Framework for Choosing

While underfill offers the absolute maximum in vibration resistance, we believe its drawbacks make it an extreme measure, not a default solution.

When to Surrender to Underfill: The Narrow Case for Rigidity

At Bester PCBA, we reserve underfill for a specific set of circumstances: extremely large and heavy BGAs (typically over 35mm) in environments with severe, high-frequency vibration, such as in aerospace, military, or heavy industrial equipment. In these applications, the risk of solder fatigue is so high that it outweighs all other concerns.

Crucially, these are often applications where rework is unplanned or the cost of a single field failure is so astronomical that sacrificing a board is an acceptable loss. If you are designing a product where failure is not an option and serviceability is not a concern, underfill is your necessary evil.

Why Corner-Bond Is Our Default Recommendation

For the vast majority of commercial, medical, and automotive electronics, we strongly advocate for corner-bonding. It provides a massive improvement in vibration and shock reliability over an unreinforced component—enough for all but the most brutal environments. It achieves this robustness without compromising the future of the product.

It preserves serviceability, reduces manufacturing complexity, and avoids the thermal stress risks of underfill. It protects the solder joints without declaring war on your service department. It is the pragmatic choice.

Key Questions to Guide Your Decision

When a client brings us this problem, we guide them through a thought process, not a flowchart. We start with the product’s life in the field. Is there a service and repair strategy, or is it a disposable unit? If it needs to be repaired, corner-bond is the immediate front-runner.

Next, we analyze the operating environment. What is the full range of thermal cycling the board will experience? In products that see significant temperature swings, the low-stress compliance of an elastomeric corner-bond offers a distinct reliability advantage. Finally, we weigh the cost of failure against the cost of manufacturing. The added process control, cycle time, and material cost of underfill can be significant and must be justified by a level of risk that corner-bonding cannot mitigate.

Beyond the Choice: Process and Material Considerations

Your decision has direct consequences on the assembly line. The choice of material is not just a design call; it’s a manufacturing process you are committing to.

The Demands of Underfill: Dispensing, Curing, and Voids

Implementing capillary underfill is a process-intensive task. It requires precise, automated dispensing to ensure the correct volume of material is applied. The curing profile, a specific time and temperature ramp, is critical to achieving the material’s properties. The biggest risk is voiding, where trapped air pockets become stress concentrators and potential failure points, completely undermining the purpose of the underfill.

The Simplicity of Corner-Bond: Application and Inspection

Corner-bonding is a far more forgiving process. It can be applied via automated dispensing or even manually for prototypes. Because the bonds are external, inspection is a simple visual check. Curing schedules are often more flexible, and the risk of process-induced defects is significantly lower. This same logic of flexible, localized reinforcement applies equally well to other large, rigid components like QFNs or ceramic capacitors that are also susceptible to vibration-induced failures.

By defaulting to the flexible, serviceable, and less complex option of corner-bonding, you often gain all the reliability you truly need without sacrificing the future of your product.