What is Epoxy Resins

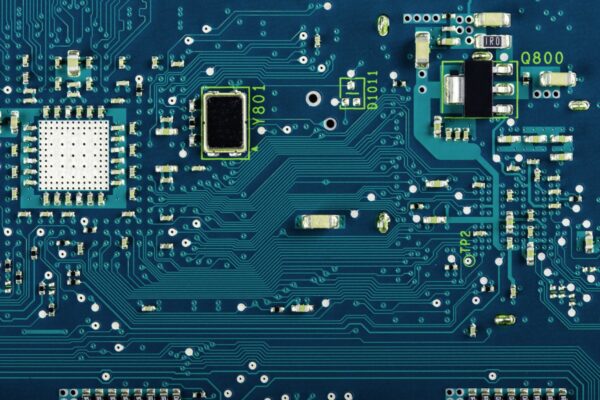

Epoxy resins are a type of thermosetting polymer commonly used for protection and insulation purposes. They are known for their excellent mechanical and electrical characteristics, making them the most commonly used material in PCB manufacturing. Epoxy resins offer good chemical resistance, thermal stability, and dielectric strength, making them suitable for withstanding harsh environmental conditions.

Epoxy resins are typically used in the form of laminates, prepregs, and Resin Coated Copper (RCC) to provide a protective layer for the components on the printed circuit board. They are composed of two liquid components that, when mixed together, undergo a chemical reaction known as curing. This curing process results in a solid and durable material that adheres firmly to the PCB.

Using epoxy resins in PCBs can protect the components against moisture, vibration, mechanical shocks, and thermal shocks. They provide a high level of protection and insulation, allowing the printed circuit board to function effectively even when fully immersed in water, solvents, or gases.

There are various types of epoxy resins available for different applications and requirements. These include thermoset epoxy resins, PTFE resins, low flow epoxy resins, high Tg epoxy resins, high CTI epoxy resins, high thermal conductive epoxy resins, low CTE epoxy resins, low Dk epoxy resins, halogen-free epoxy resins, lead-free epoxy resins, polyimide modified epoxy resins, ceramic filled epoxy resins, and BT modified epoxy resins. Each type has its own unique properties and characteristics, allowing for customization and optimization of PCB designs based on specific requirements.