1: When the Idea Is Not Enough

We will guide you throughout the process of developing a product, from the very conception of the idea to the final testing and product verification.

Every electronic product started as an idea. iPhone started as an idea in Steve Jobs’ mind. However, many people have great ideas, and not all of them create great products like Apple’s ultra-famous smartphone.

Why does this happen? Not all entrepreneurs have the resources needed to develop their idea, or maybe they do, but don’t know how to use them.

What resources are we talking about? Knowledge and time.

Knowledge

A degree in Electronics is not mandatory, but you need to have a background on Electronics, Circuit design, PCB layout, firmware and software development and mechanical design. As technology evolves so quickly, staying up to date with new devices, programming languages, communication networks such as 5G, BLE, LoraWAN, among others, are a must for anyone involved in Hardware Design.

Time

One of the most valuable assets entrepreneurs have, and because of that you will need to use it wisely, when a product is being developed a lot of things occur in parallel, marketing, material sourcing, research, etc. And you may end up struggling to find time to complete all the tasks such as the PCB Layout, selecting the right PCB manufacturer, testing the prototypes, developing firmware or designing the enclosure.

How do successful entrepreneurs use these resources? Read on.

2: Grab Pen and Paper and a Breadboard

That idea in your mind won’t become a reality by itself. You must grab pen and paper and start drafting circuits. Or get someone to do it for you.

This is when things start getting complicated, and we could say that circuit design is the first filter of the hardware design process, because many entrepreneurs do not have the knowledge to do it, or they lack the network to find the appropriate engineering partners. This situation creates a need to learn circuit design, but what happens when you don’t have the time to do so, or simply electronics design is not your thing?

There’s no need to be worried. You can always contact design firms that specialize in circuit and electronics design with extensive experience in the matter. This way, the process will be in the hands of experts who will get the job done in a shorter period of time, thus letting you focus on marketing, finding investors, and other business-related activities.

The result of the circuit design stage would be a schematic diagram, no matter if it’s just a hand sketched one. A quick proof of concept using a breadboard can be made during this stage as well.

Once you’ve figured out the circuit design stage, it’s time to drop all this information into a computer program that will allow you to create the digital schematics for your product, thus beginning the PCB design & Layout process.

3: Hands on the PCB Layout

So, at this point you have a blueprint and initial validation of the design’s functional behavior. So, what’s next? How do you transform what you have into an actual PCB? First, you have to know that fabrication and assembly files are imperative.

Fabrication and assembly files include all the data PCB houses need to make your boards, but in order to create these files, you need a computer program that allows you to do schematic capture and PCB layout. This software package is known as CAD software. Multiple options are available in the market. Some are free but have limited functionalities, and the more powerful ones require a paid license, representing an additional development cost that might not be worth it for the entrepreneur.

Additionally, the PCB layout stage requires a set of skills and good practices that can only be acquired through experience: routing techniques, proper component placement, considerations about electromagnetic interference and noise reduction, etc. Complex boards, like PC motherboards and high-speed devices, require an even higher level of expertise. So, if you happen to decide to walk the hard road of doing the PCB layout on your own, you will be facing two important challenges: saving several thousand dollars to buy adequate CAD software and taking the time to learn this software, develop your PCB Design skills and polish them.

In summary, this stage must be executed by an experienced professional if you want to deliver a final product of high quality. We can offer you PCB design services if your business doesn’t have an in-house engineering department.

Once your PCB is designed and fabrication & assembly files are generated, you are ready to have your boards made!

4: Time to Look for a Supplier

Once the PCB layout is complete, the following step will be to transform it into a physical device that will let you verify your design and perform functional testing. This can be an overwhelming task, because there are many variables to consider and barriers to overcome.

Variables

Each electronic design is different and, as such, requires particular specifications. For example, layer count, trace width/spacing, or hole size are just some of the specifications you need to take into account when going to the manufacturing stage. The size of components is also crucial for assembly, as some are so small not all equipment will be able to handle them. Depending on how complex your board is, you may find it necessary to consider different suppliers that suit your requirements better. For simple designs, you will prefer a contractor with good quality and quick turnaround. However, for complex designs, your main consideration should be the supplier’s capabilities.

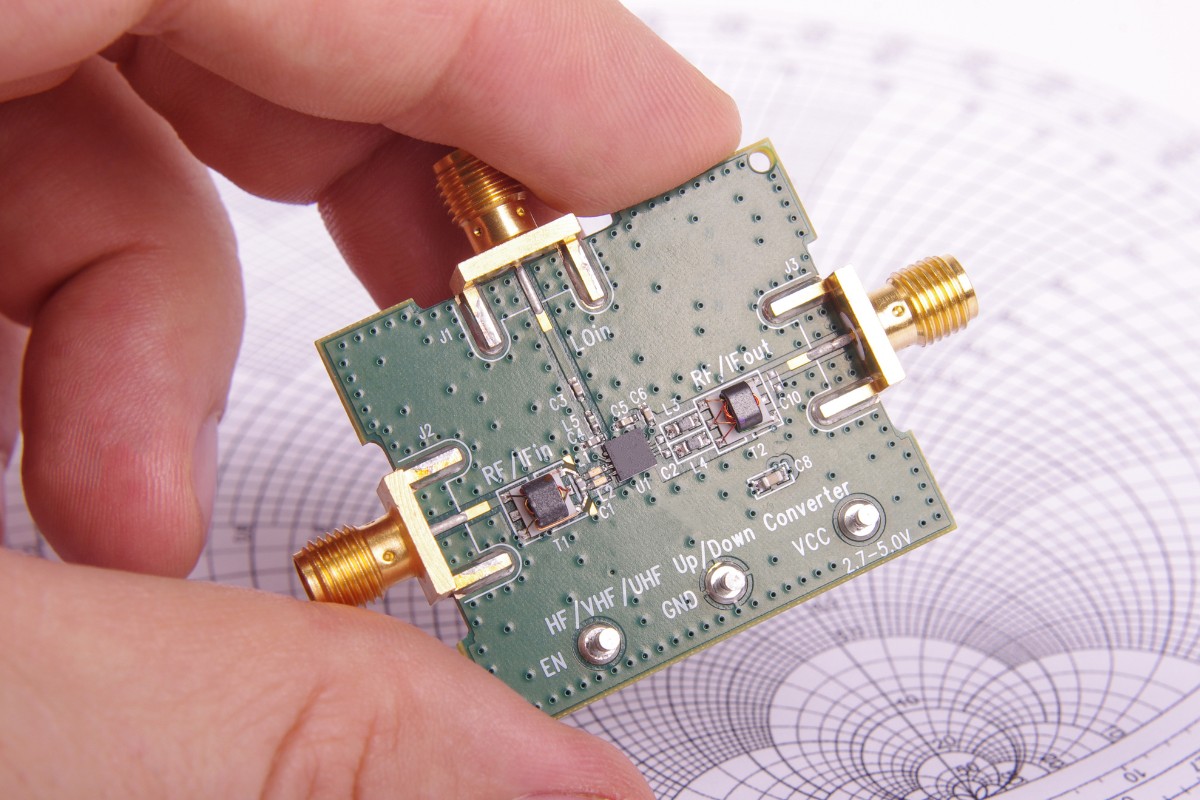

Also, if the design falls into a very specific application, like Radio Frequency, High Speed circuits or Military/Aerospace technology, the selection of the contractor is a life or death decision from a business point of view. Selecting the wrong PCB house could compromise the future of your product.

Barriers

Although the PCB industry was once huge in the US, the reality nowadays is that most of the big players are overseas; China, Taiwan, and India are the go-to places for printed circuits. Low labor costs in these countries are the main force behind this trend; now, you can contact a PCB Manufacturer or an Assembly house in Asia and obtain a batch of PCBs for just a fraction of what you would need to pay to have them made in the US.

However, not everything is perfect. Lead times are obviously shorter in the US because of the transit times and the absence of customs delays. Additionally, the time zone differences between Asia and America could easily transform a simple quote and ordering process into a week’s long torture, and in some cases, the language barrier will end up complicating things even more with emails and calls going back and forth, sometimes just to clarify a tiny detail.

5: Firmware, Testing, Mechanical Design

At this point, you should have a fully assembled circuit board in your hands and your prototype ready for programming (if needed) and testing. But, again, what happens if you don’t have the equipment, the knowledge, the time, or you simply just feel safer having a professional electronics designer doing it for you?

We have the tools to provide additional services that are important in pursuing the goal of getting a final product: firmware development, testing and enclosure design.

Nowadays, most electronic products are digital and require some programming. We can do it thanks to our experience with embedded development and microcontrollers.

Testing is important since you want to ensure that your product works as intended. We can perform testing procedures in order to guarantee the proper behavior of the design.

Finally, if you plan to sell a product, it will need an enclosure to protect it from the environment and mechanical shocks. We will gladly help you accomplish that task as well.

We hope you enjoyed this series of articles on all the steps you need to transform your idea into a real product, if you are interested in any of the services described in this series, do not hesitate to contact us, at the end of the day it is our job to help you! Our main goal is to help small and medium-sized businesses, entrepreneurs with amazing ideas in need of that jump-start to materialize them.