What is Component Sourcing

Components sourcing is the process of identifying and acquiring the necessary electronic components required for the production of printed circuit boards, which involves finding and procuring specific components listed in the Bill of Materials (BOM) used for PCB assembly.

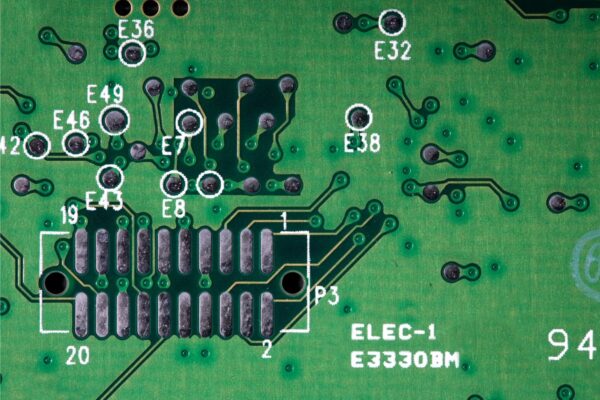

The BOM is a crucial document providing detailed information about each component part, including reference designators, quantities required, manufacturers, and part numbers. It guides component sourcing, allowing manufacturers to analyze and identify the components needed for PCB assembly.

The components sourcing process involves several steps. Firstly, the BOM is used to identify the specific components required for the PCB assembly. Once identified, manufacturers research and identify potential suppliers for each component, considering factors such as reliability, reputation, and the ability to provide components within the specified timeframe.

After identifying suppliers, manufacturers check the availability of components and the lead time required for delivery. Price and cost analysis is conducted, comparing prices from different suppliers and considering factors such as volume discounts, shipping costs, and additional fees.

Quality assurance is also a critical aspect of component sourcing. Manufacturers review supplier reputation, certifications, and product specifications to ensure the sourced components meet the required quality standards. Any specific quality requirements specified by the customer are also taken into consideration.

Once the components have been identified, suppliers selected, and pricing and quality considerations made, manufacturers initiate the procurement and ordering process. This involves placing orders with the selected suppliers and coordinating the delivery of components to the PCB assembly facility.

Effective component sourcing also involves managing inventory levels to ensure an adequate supply of components for ongoing production. This includes monitoring stock levels, reordering components as needed, and optimizing inventory to minimize costs and prevent shortages or excesses.