Blog

-

QFN Thermal Pad Paste Patterns That Rework Clean

A solid solder paste aperture on a QFN thermal pad creates a massive heat sink, making rework on dense analog boards destructive and risking collateral damage to nearby components. The solution is a strategic reduction in paste volume using windowpane stencil patterns and thinner stencils, which localizes heat and enables clean, safe component replacement without compromising essential thermal performance.

-

Masking That Keeps Test Pads Alive

Conformal coating is essential for protecting printed circuit boards from environmental hazards, but it creates an insulating barrier that can make test pads inaccessible. Without precise masking, a coated PCB becomes untestable and unrepairable, turning a valuable product into e-waste. The right masking strategy, whether using custom boots or CNC selective coating, is crucial for maintaining a board’s serviceability and long-term value.

-

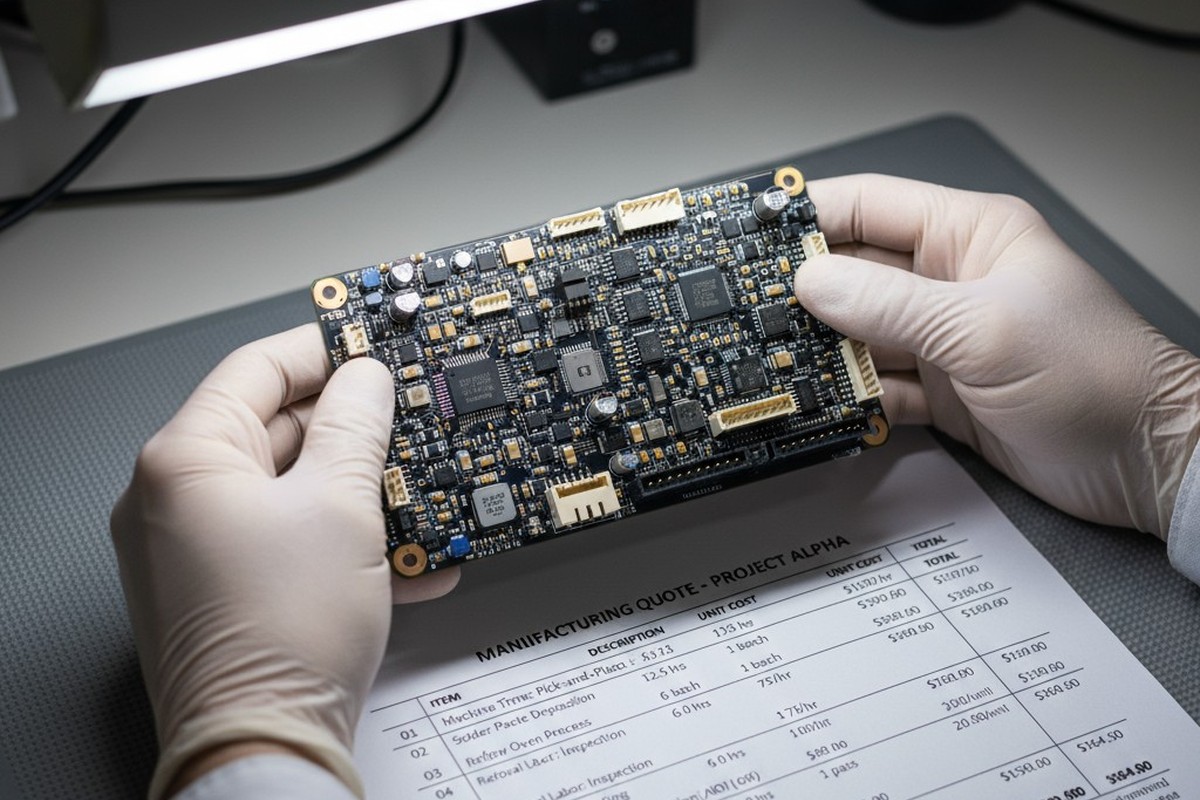

Pricing Transparency for Complex PCB Assemblies

Opaque pricing for complex PCB assemblies creates significant risk, crippling budgets and obscuring the link between design choices and cost. We advocate for a transparent, time-driven quoting methodology built on disclosed risk buffers and validation against production data. This approach reduces your risk and provides the tools to audit any manufacturer’s quote, ensuring the price reflects reality, not hidden margins or optimistic guesses.

-

When AOI Goes Blind: Inspection Strategies for Dark Solder Masks and Ultra-Fine-Pitch Assembly

Modern electronics with matte-black solder masks and ultra-fine-pitch components challenge traditional Automated Optical Inspection (AOI), causing high rates of false positives and costly escapes. To overcome these physical limitations, manufacturers must adopt a multi-method strategy, integrating 3D Solder Paste Inspection and Automated X-ray Inspection to ensure reliable quality control where optical systems fail.

-

The Unseen Stress: Solder, Reliability, and the Automotive Future

In the brutal environment of a modern vehicle, where electronics endure a life of violent temperature swings and constant vibration, the solder joint is the point of greatest faith.

-

The Unseen Economics of Small Boards

In the world of compact electronics, particularly within the hyper-competitive sphere of IoT devices, success is often measured in fractions of a cent.