It’s really not so easy to identify the single-sided PCB and double-sided PCB because they appear quite similar at first glance. Let’s explore how to distinguish them.

Understanding Single-Sided PCBs

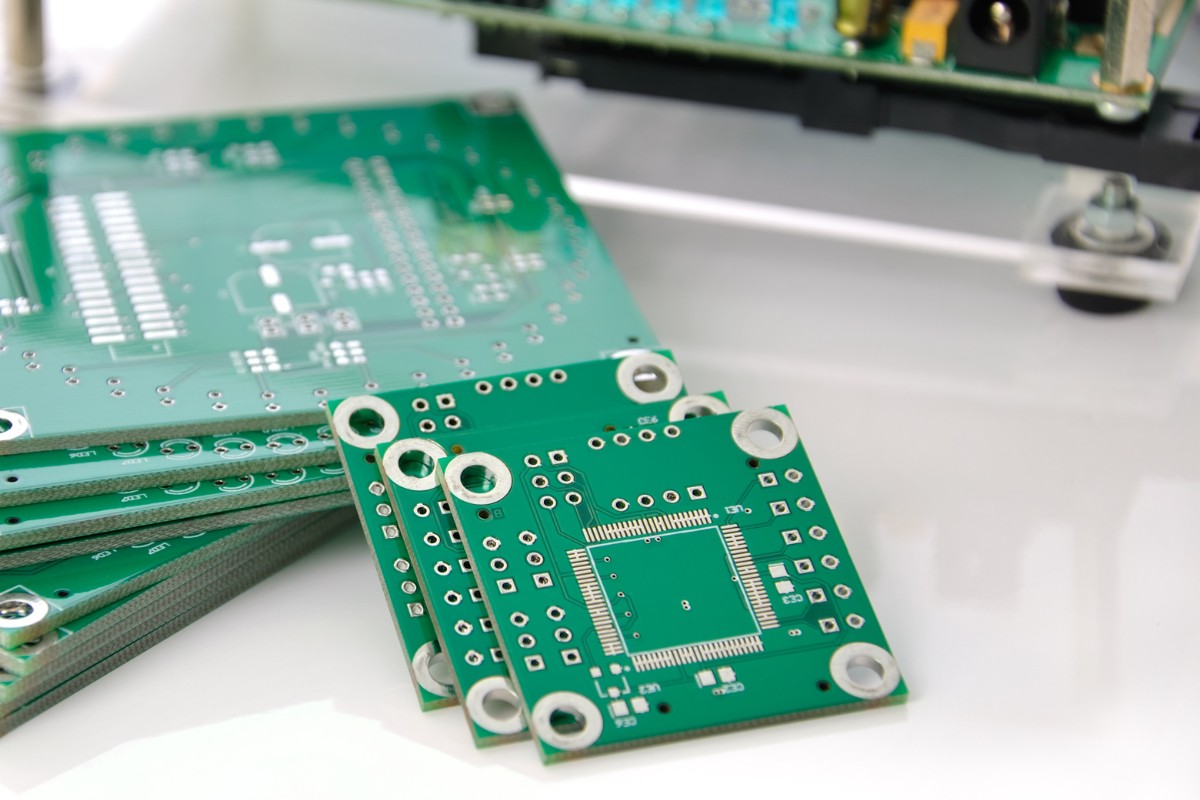

First of all, the single-sided PCB is the most basic type of PCB, featuring components on one side and circuits on the other. This is why we refer to them as single-sided. Since it only has one circuit side, the design rules are quite strict: there should be no crossing lines at all. The focus is primarily on screen printing, which involves pasting the solder mask on the board, and after etching, the legend is printed on the board. Drilling is essential for mounting the components. Single-sided PCBs are typically used in simpler devices due to their design limitations and lower cost, making them ideal for high-volume manufacturing.

Exploring Double-Sided PCBs

On the other hand, double-sided PCBs offer more complexity and versatility. They come in many types and with hundreds of specifications to choose from. These PCBs have circuits on both sides, and it’s crucial to connect both sides through holes, commonly known as vias. These vias are usually covered with metal to connect circuits on both sides effectively. The larger total area of double-sided boards means the design rules are less restrictive compared to single-sided boards. Double-sided PCBs are popular in the market because they are found in more complex devices like smartphones and laptops, offering better functionality and connectivity.

Popularity and Fabrication

Strictly speaking, double-sided PCBs are more popular in the PCB market. You can see them almost everywhere, from consumer electronics to industrial machinery. Moreover, double-sided boards are easier to order and fabricate, which adds to their widespread use.

Cost and Manufacturing Process Differences

Cost Implications

The cost of manufacturing double-sided PCBs is generally higher than that of single-sided PCBs due to the additional processes involved, such as drilling and plating vias. However, the enhanced functionality per unit area often justifies the extra cost, especially in compact electronic devices.

Manufacturing Differences

The manufacturing process for double-sided PCBs involves several additional steps compared to single-sided PCBs. After the initial layer of copper is etched away to form the circuit pattern on both sides, vias are drilled and plated to establish connections between the layers. This process requires precise control and advanced machinery, which can increase production time and cost.

Technological Limitations and Advancements

As technology advances, the limitations of single-sided PCBs become more apparent, especially in their inability to support complex circuits and multiple components. Double-sided PCBs, however, have evolved to accommodate more advanced surface-mount technology and denser circuit layouts. Innovations in PCB design software and manufacturing techniques continue to push the boundaries of what double-sided PCBs can achieve, making them indispensable in modern electronics design.

All in all, both types of boards are very useful. But if you ask me my preference, I would choose double-sided for its wider usage and easier fabrication. Whether you are designing a simple toy or a sophisticated computer system, understanding the differences between these PCB types is crucial in choosing the right one for your needs.