Blog

-

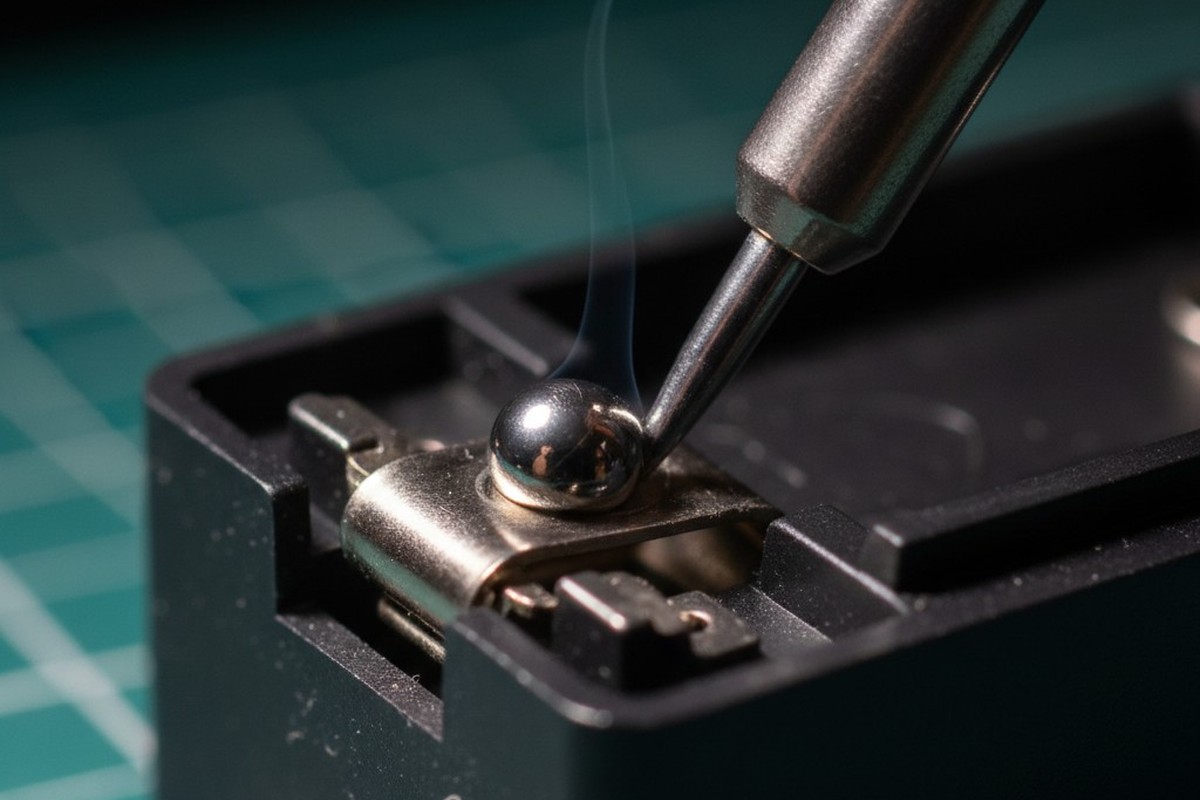

The Physics of Frustration: Why Your Battery Holder Won’t Take Solder

If solder won’t wet your battery holder, you’re likely fighting a stubborn nickel oxide layer, not failing at technique. Discover why more heat is the wrong approach and how to properly prepare the surface with aggressive flux or abrasion for a strong, reliable bond.

-

The Physics of a Partial Reel: Why We Seal Before We Sleep

A partial reel of electronic components exposed to air is a ticking time bomb. The physics of moisture absorption can cause catastrophic failures during manufacturing, a phenomenon known as popcorning. Understanding and implementing a strict vacuum-sealing protocol is the only way to prevent costly scrap and ensure reliable products.

-

The “Golden Sample” is a Trap: Why Engineering-Grade FAI Matters

The “Golden Sample” from your contract manufacturer proves a design can work, but it doesn’t prove the manufacturing process is stable for mass production. Relying on a simple “Pass/Fail” FAI report is a trap that hides process flaws and leads to costly production failures.

-

The Physics of Placement: Why Rail Fiducials Fail Fine-Pitch Designs

Relying on rail fiducials for fine-pitch component placement is a recipe for disaster due to material distortion and geometric leverage. This article explains the physics of placement failures and why local fiducials are the only way to guarantee accurate assembly for high-density designs.

-

The Consigned Kit Audit: Catching Shortages Before the Line Stops

A consigned kit audit is the physical firewall that prevents manufacturing line stoppages. We verify component counts, integrity, and packaging to ensure the parts you provide are machine-ready, catching shortages and issues before they can halt production and compromise your project schedule.

-

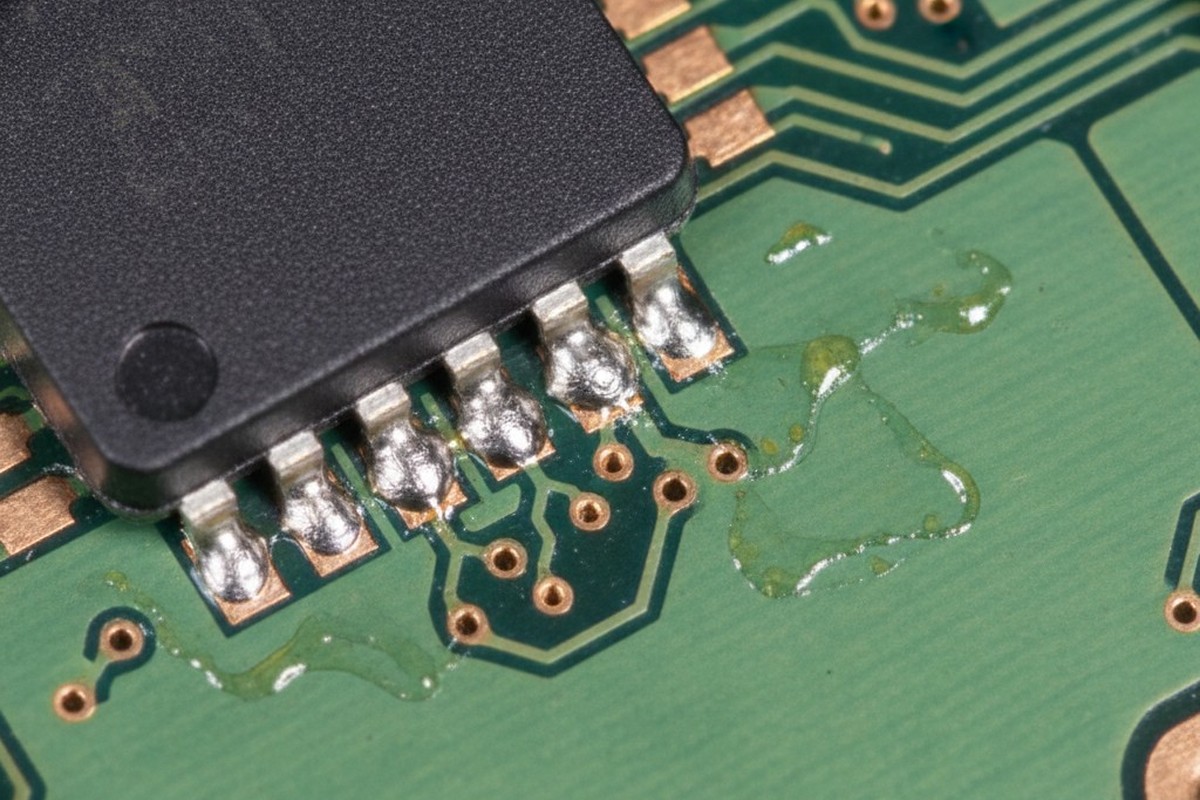

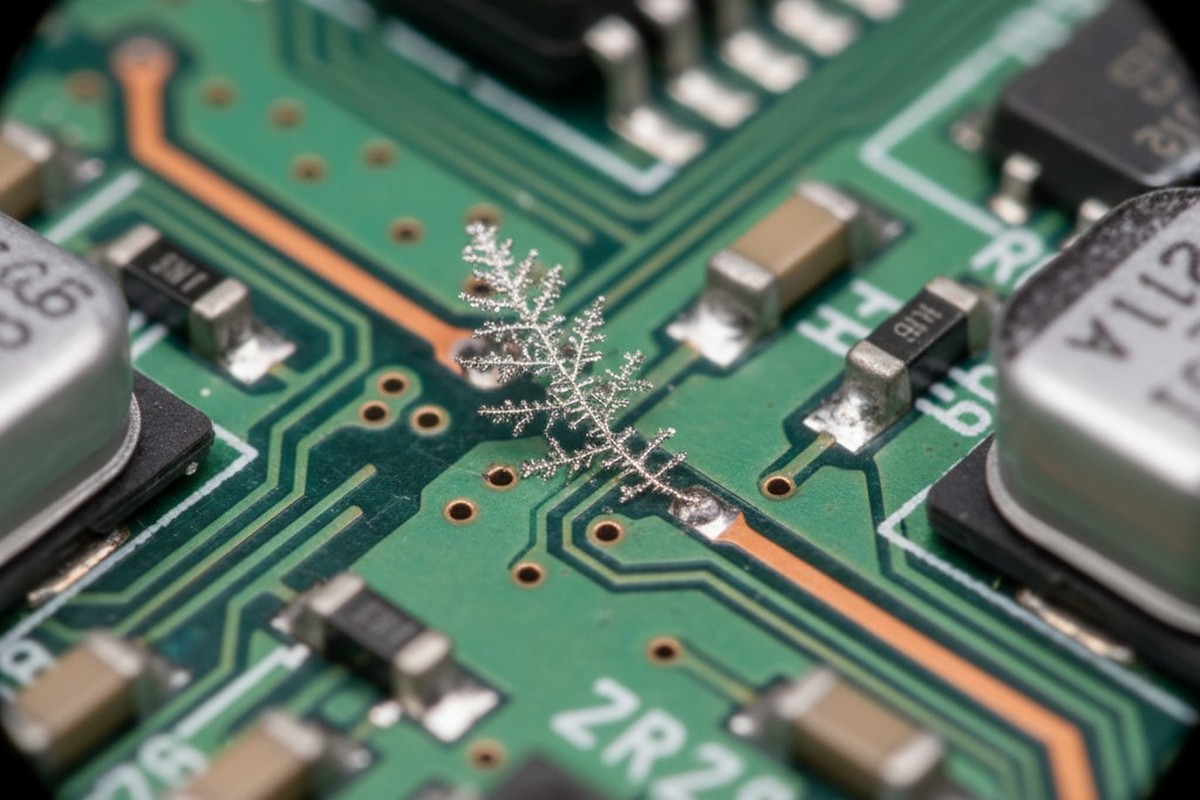

The Invisible Battery: Why High-Voltage Electronics Require Chemical Cleaning

Visually perfect high-voltage electronics can fail catastrophically due to invisible, chemical residues left from flux. These residues create a ‘battery’ on the board, leading to electrochemical migration and short circuits that can only be prevented with a precise chemical cleaning process.