Blog

-

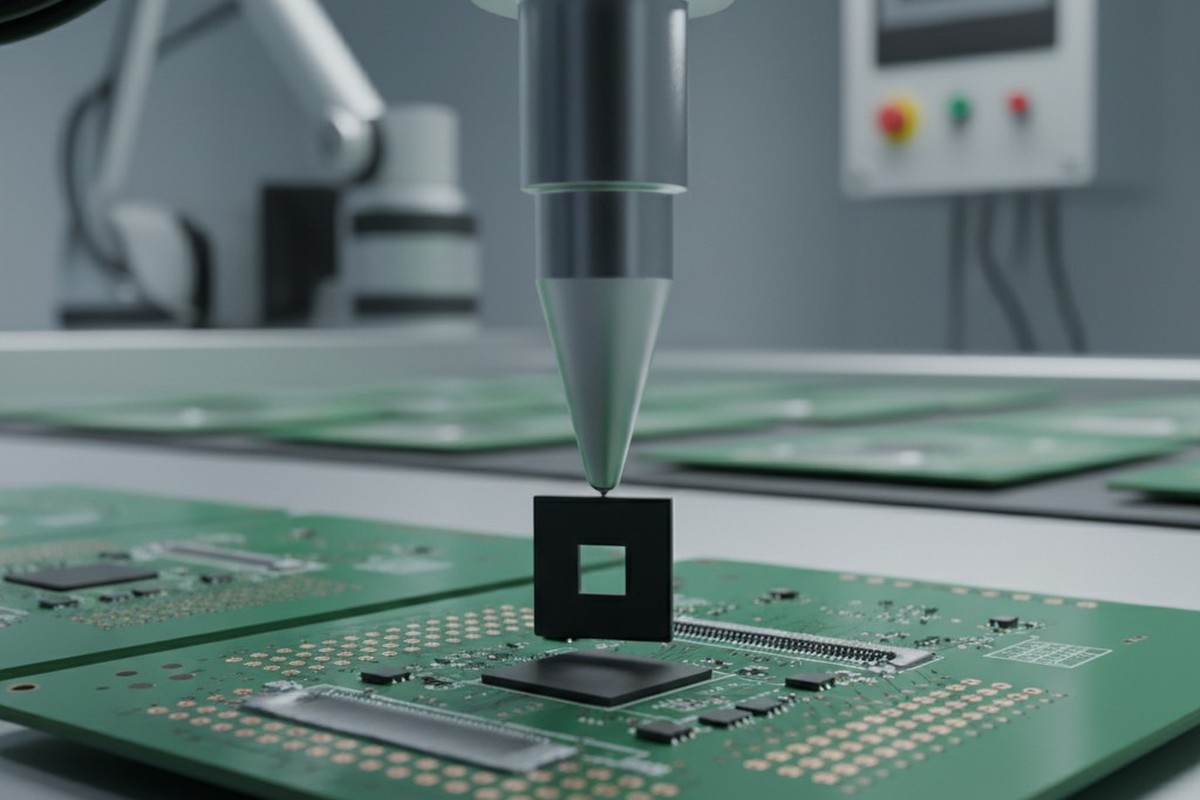

The Physics of Adhesion: Why Heavy Capacitors Demand Automated Staking

Heavy components like capacitors are prone to failure from vibration in automotive environments. Manual staking with silicone is unreliable; only automated dispensing of engineered adhesives provides the required structural support to ensure long-term reliability.

-

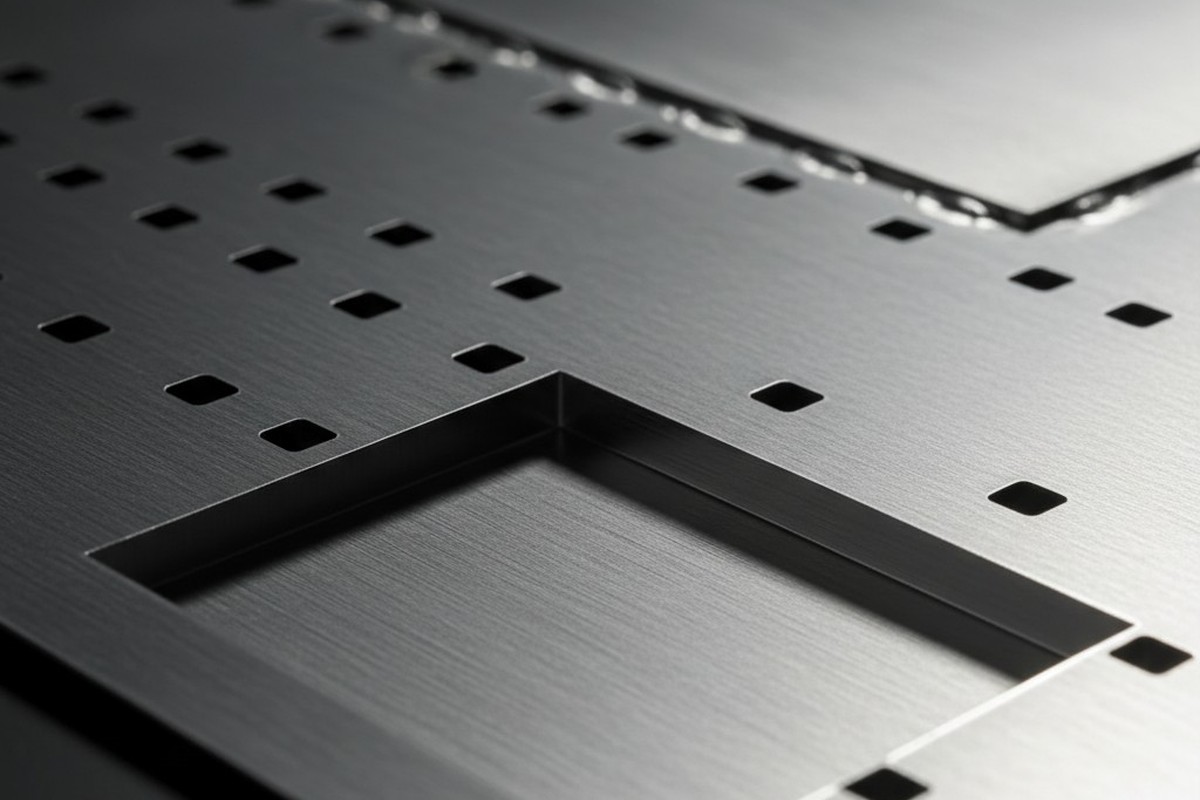

The Hidden Z-Axis: Why Your Stencil Is Wrong

Treating a solder paste stencil as a simple 2D copy of your board’s pads is the most common cause of assembly defects. Manufacturing success depends on understanding the Z-axis—the solder volume—and engineering the stencil with features like steps and window panes to account for the physics of paste deposition.

-

Gravity is Undefeated: Managing Second-Side Reflow Risks

When assembling double-sided PCBs, gravity threatens to pull heavy components off the bottom side during reflow soldering. This article explores the physics behind this risk and outlines the only effective solutions, from superior design choices to manufacturing fixtures and the pitfalls of using adhesives.

-

The Paper Match: Why “Compatible” Alternates Fail on the Factory Floor

Relying on a distributor’s ‘compatible’ or ‘drop-in replacement’ flag for alternate components is a costly mistake. Seemingly minor differences in mechanical dimensions or electrical characteristics, not shown in search filters, can lead to catastrophic failures on the assembly line.

-

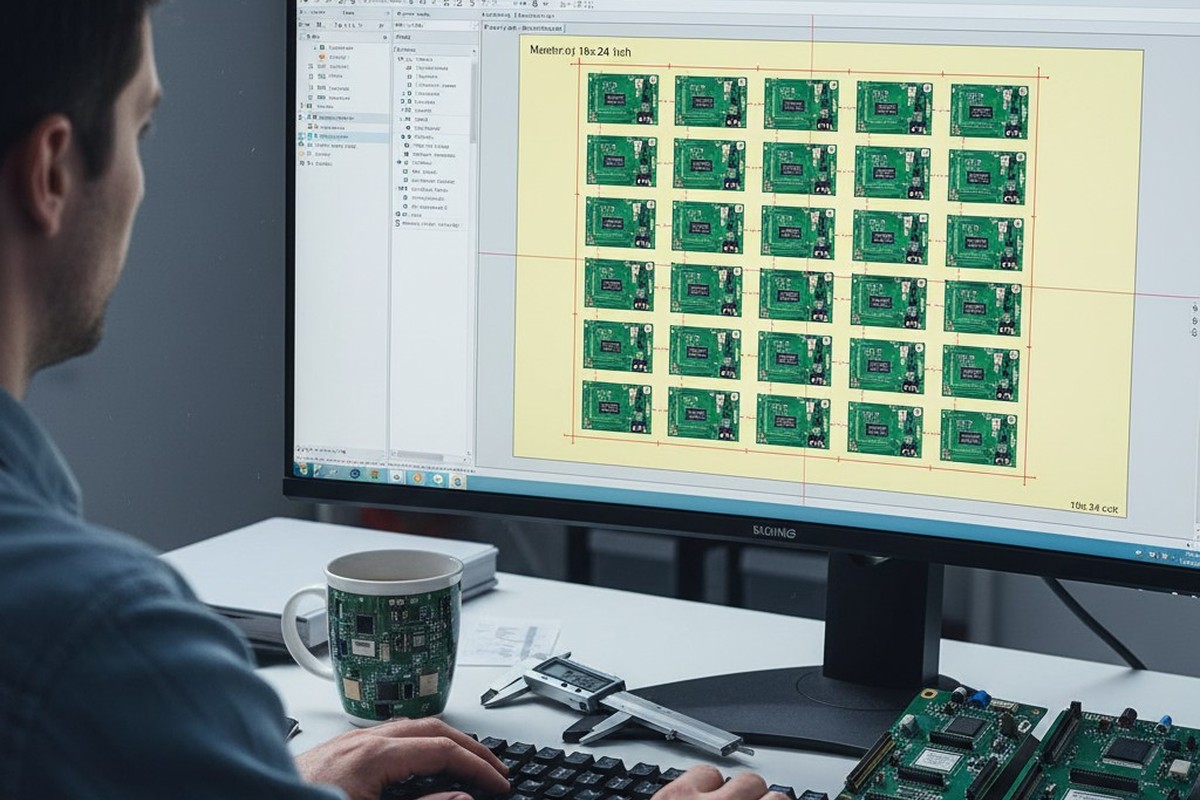

The Physics of Profit: How Panel Utilization Math Saves 20% on PCB Costs

Your PCB’s final cost is not determined by its size, but by how many units fit onto a standard manufacturing panel. An arbitrary 2mm change in your board’s dimensions can increase yield by 33%, directly impacting your bottom line by reducing wasted material.

-

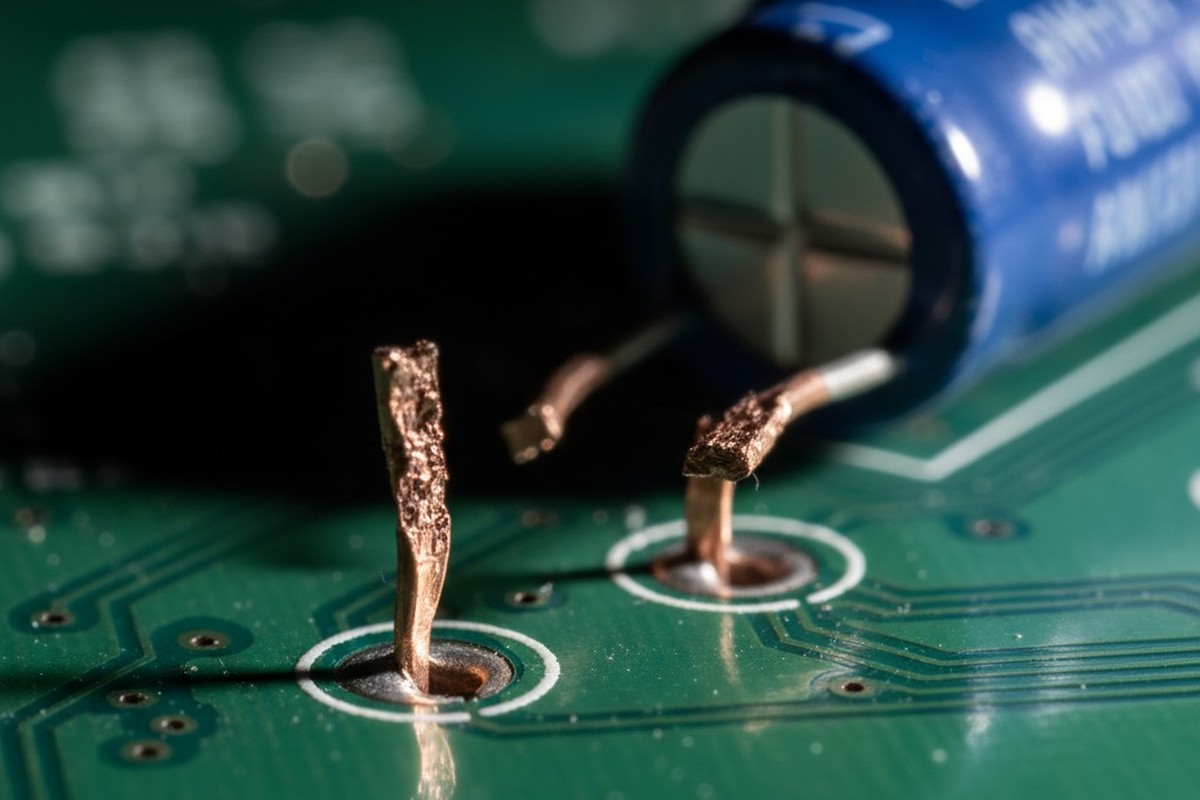

Heavy Copper Thermal Reliefs: The War Between Amps and Solder

High-current PCB design often fails during manufacturing. The massive copper planes needed to carry amps act as heat sinks, preventing reliable solder joints and causing catastrophic field failures. Learn why direct connections are a myth and how to correctly calculate thermal reliefs to balance current capacity with manufacturability.