Blog

-

Beyond the Snap: Smart Panelization for Irregularly Shaped PCBs

Treating PCB panelization as an afterthought is a costly mistake, especially for irregularly shaped boards. Standard mouse-bites cause stress fractures and scrap, but an engineered approach using routed tabs or laser depaneling protects product quality, reduces waste, and defends your budget by ensuring a higher yield of reliable boards.

-

The Engineer’s Guide to Eliminating Voids in Power Stage Assembly

Microscopic voids trapped in solder joints under power components can cause severe overheating and product failure. These silent killers compromise thermal performance by insulating heat pathways. This guide explains how a systematic approach, combining advanced stencil design and controlled vacuum reflow processes, can eliminate these dangerous voids, ensuring the reliability and longevity of high-power electronics assemblies.

-

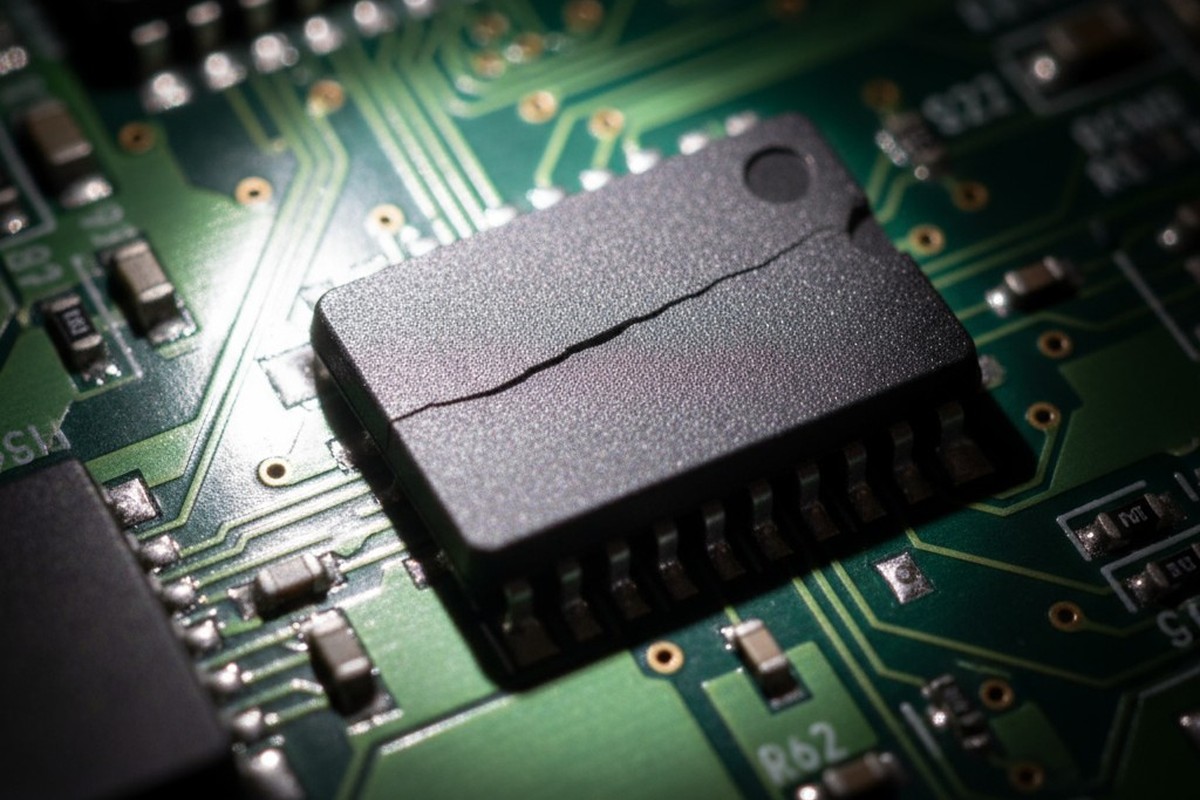

When Broker Buys Are Unavoidable: The Bester PCBA Guardrails

Component shortages often force manufacturers to use the open broker market, a path filled with risks like counterfeit parts. At Bester PCBA, we refuse to gamble with your product. We enforce mandatory, multi-layered guardrails—including XRF analysis, decapsulation, and marking permanency tests—to ensure every component is authentic and reliable before it ever reaches your board.

-

Beyond Generic: Engineering Selective Solder Pallets for Tall Components

Generic selective solder pallets often fail with complex assemblies, leading to scorched components and solder bridging. We treat the pallet as a piece of custom process-control hardware, sculpting it for thermal management and pairing it with a data-driven soldering program to eliminate guesswork, achieve zero defects, and ensure maximally efficient, honest cycle times.

-

MSL Handling That Stops Popcorn Failures at the Line

Popcorn failures in electronic components, caused by moisture vaporizing during reflow soldering, can scrap entire boards. This guide provides a complete operational framework for handling MSL3 and higher components, covering the practical steps to track, store, and bake parts to prevent these costly and predictable failures. It focuses on creating reliable, maintainable systems for teams of any size, ensuring component integrity from storage to assembly.

-

DFM Moves That Prevent a Respin on Mixed QFN and Micro-BGA Layouts

Mixing QFN and micro-BGA packages on a PCB creates significant manufacturing challenges that often lead to costly respins. This article details five critical DFM strategies, from solder paste aperture tuning to fiducial placement, that reconcile their conflicting requirements and help you avoid predictable first-build failures.