Blog

-

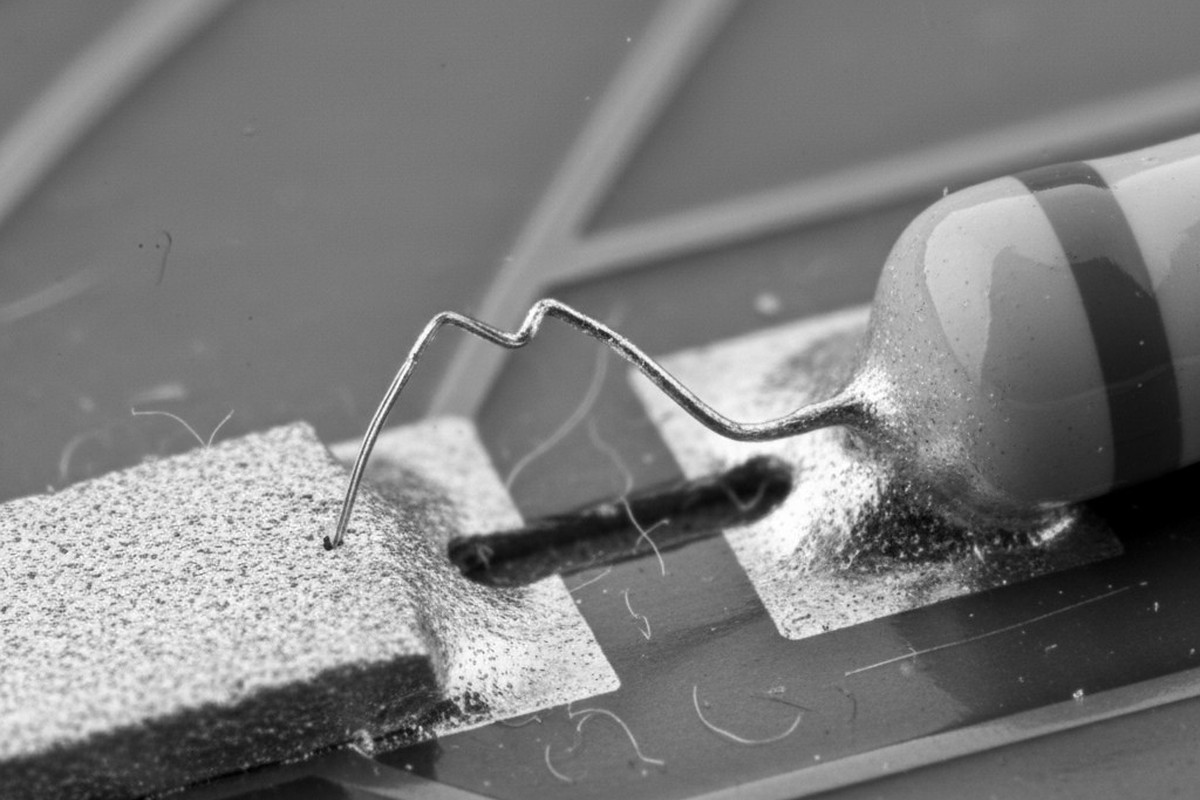

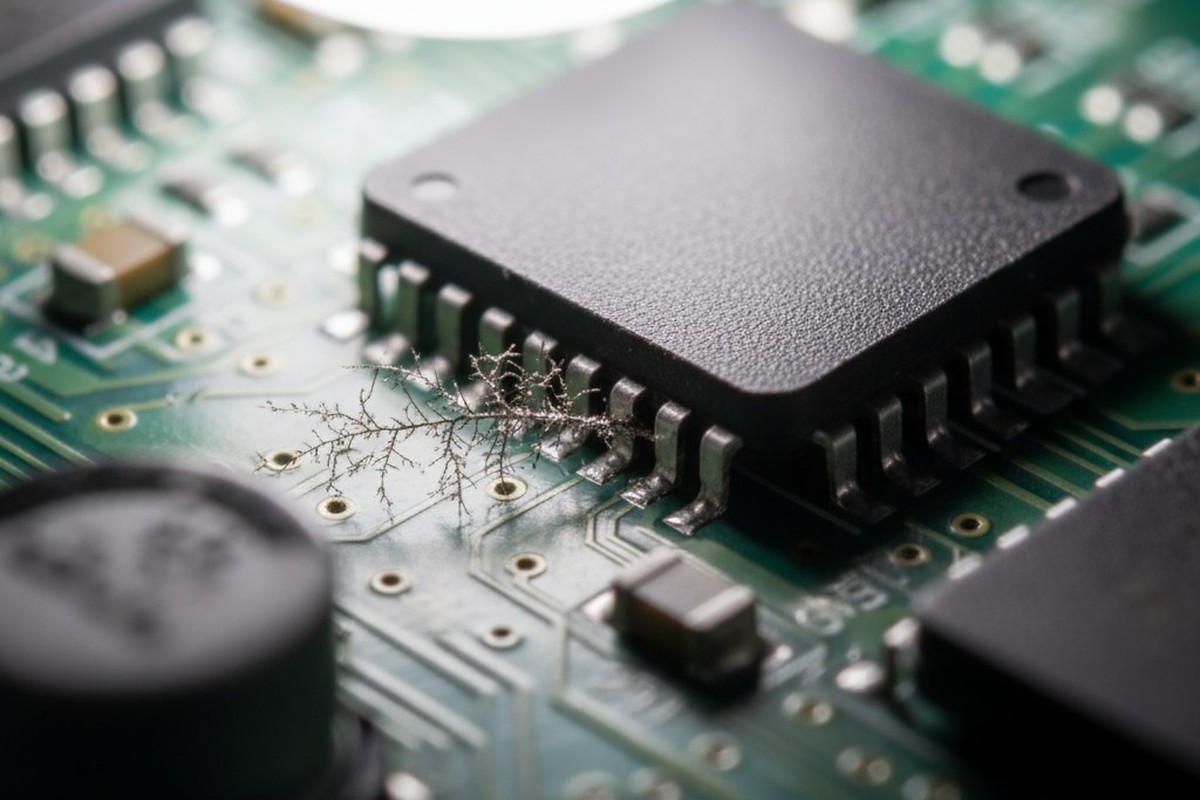

The Silent Short: Why Tin Whiskers Thrive in Low-Power Electronics

Tin whiskers are a significant threat to long-life, low-power electronics, causing silent short circuits even in stable, room-temperature environments. This insidious failure mode is driven by compressive stress in tin plating, but can be effectively mitigated by choosing the right surface finish, specifically a system of matte tin over a nickel underplate with a post-plating anneal.

-

The HiP Defect on High Thermal Mass Boards: Why More Paste Is Never the Answer

When faced with head-in-pillow (HiP) defects on high thermal mass boards, the instinct is to add more solder paste, but this approach fails to address the root cause. The true problem is dynamic board warpage driven by thermal gradients, which can only be solved by mastering the reflow profile, ensuring proper mechanical support, and selecting a high-tack solder paste to achieve a reliable connection.

-

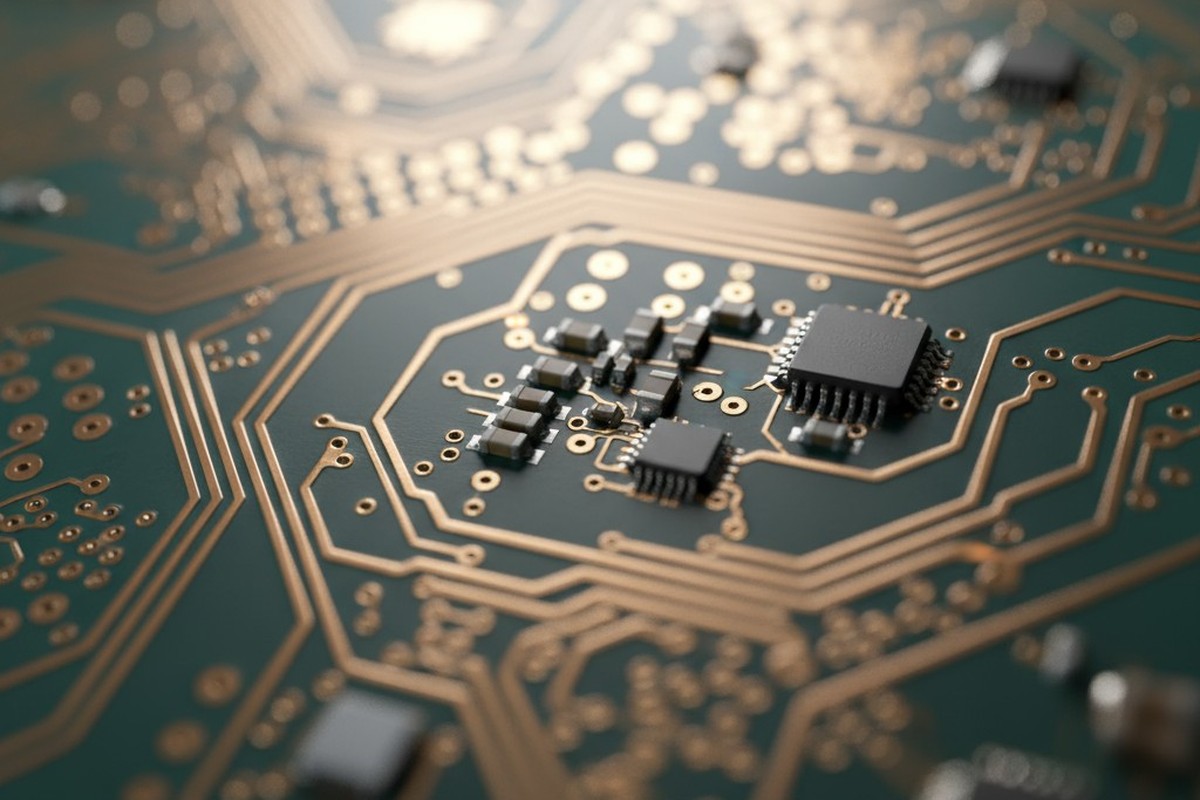

The Penny-Wise, Pound-Foolish Case Against OSP

OSP may seem like a cost-effective PCB surface finish, but its short shelf life and vulnerability to heat create significant risks for New Product Introductions. This hidden liability often leads to solderability failures and expensive rework, turning initial savings into major project delays and costs that could be avoided with a more robust finish like ENIG.

-

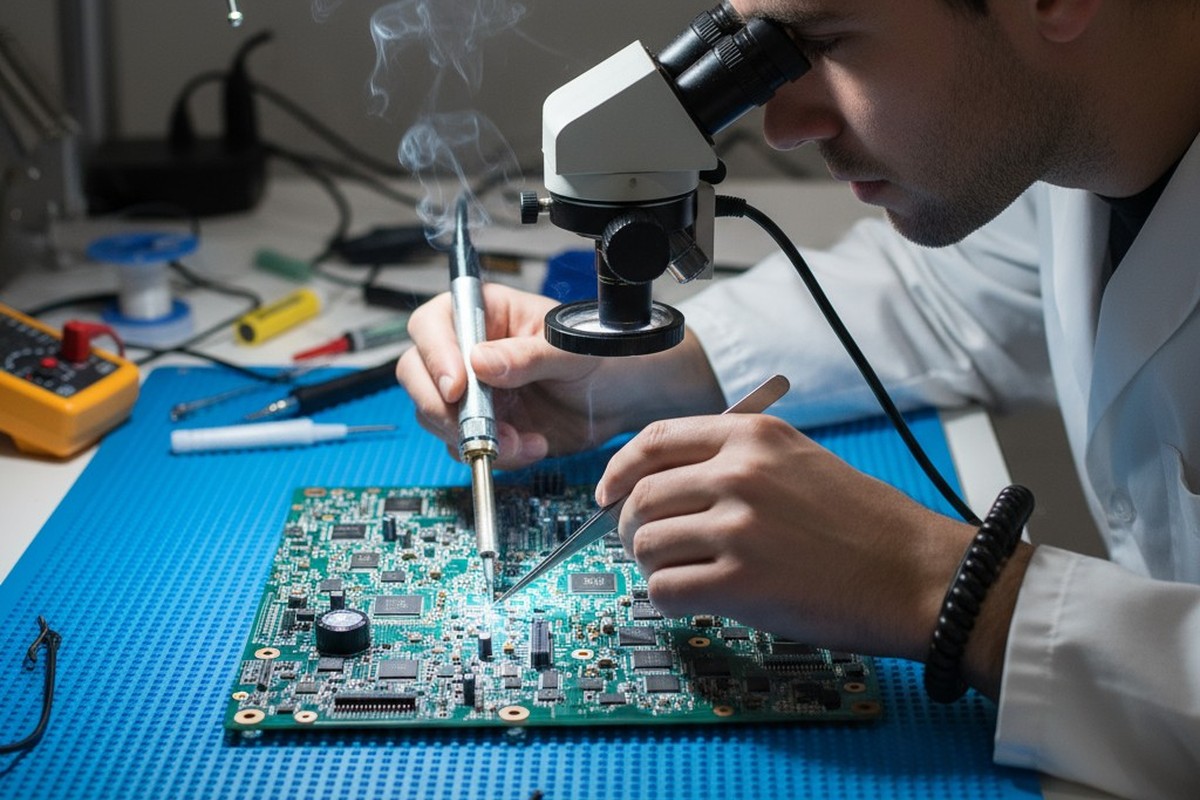

The 48-Hour Loop: How Bester PCBA’s Rapid Failure Analysis Stops Margin Bleed

Traditional PCBA failure analysis is too slow, allowing minor defects to become major financial liabilities as more faulty units are produced and shipped. Bester PCBA’s 48-hour rapid failure analysis loop breaks this cycle by delivering definitive root cause analysis and actionable feedback, stopping issues from compounding and protecting profit margins before they bleed.

-

The Unseen Bottleneck: Why Your Firmware Loading Strategy Is Strangling SMT Throughput

On-line firmware programming is a silent killer of SMT throughput, holding your entire production line hostage. By decoupling programming from assembly and using parallel methods like off-line gang programming or dedicated high-speed flashing stations, you can eliminate this critical bottleneck and keep your line moving at maximum speed.

-

The Cleanliness Metric That Actually Matters: Why Your ROSE Test Is Lying to You

The standard ROSE test for PCB cleanliness provides a false sense of security, leading to costly field failures from corrosion and short circuits. Its averaging method masks dangerous localized contamination under components, a problem solved by using Ion Chromatography for a detailed chemical analysis that truly predicts long-term reliability.