Blog

-

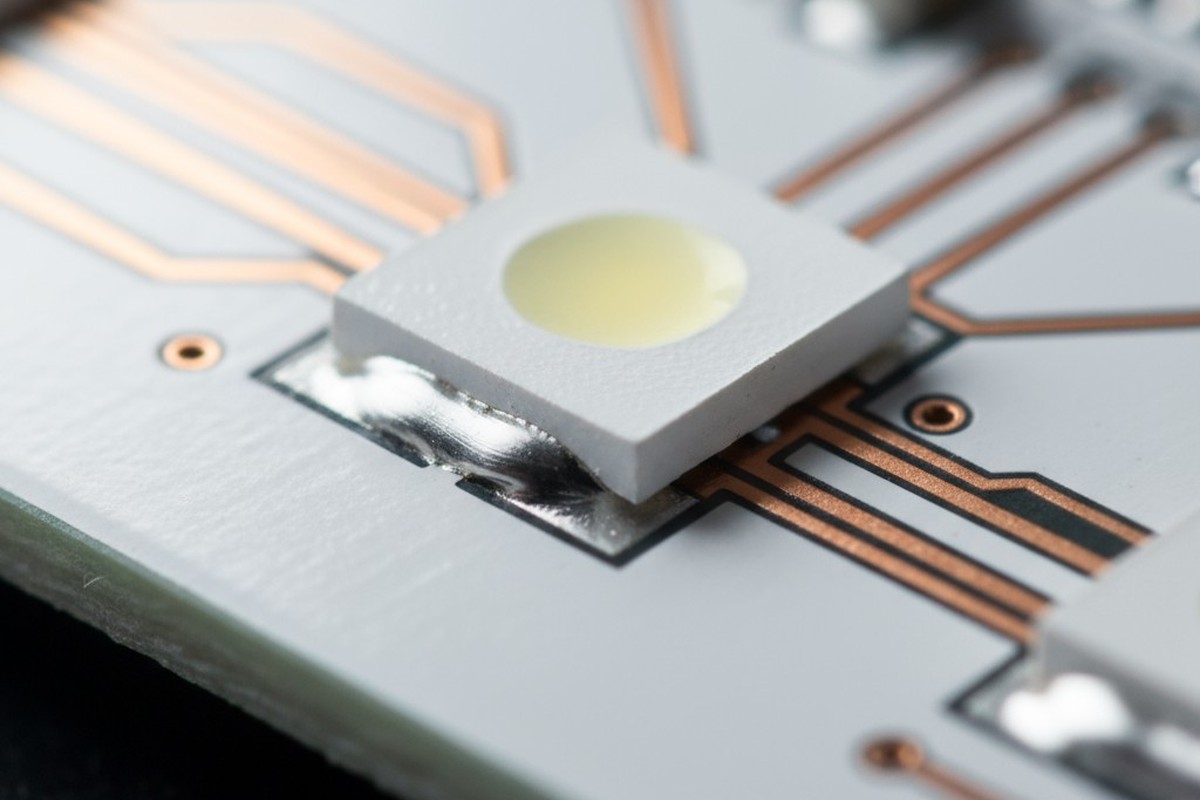

LED MCPCBs: Voids, the Thermal Stack, and the Lumen Droop Trap

Premature LED dimming, or lumen droop, is often misdiagnosed as an electrical issue. The root cause is thermal: heat trapped at the LED junction due to voids in the thermal stack. This article explains why focusing on thermal interface materials and manufacturing processes like vacuum reflow is critical for creating reliable, long-lasting LED products.

-

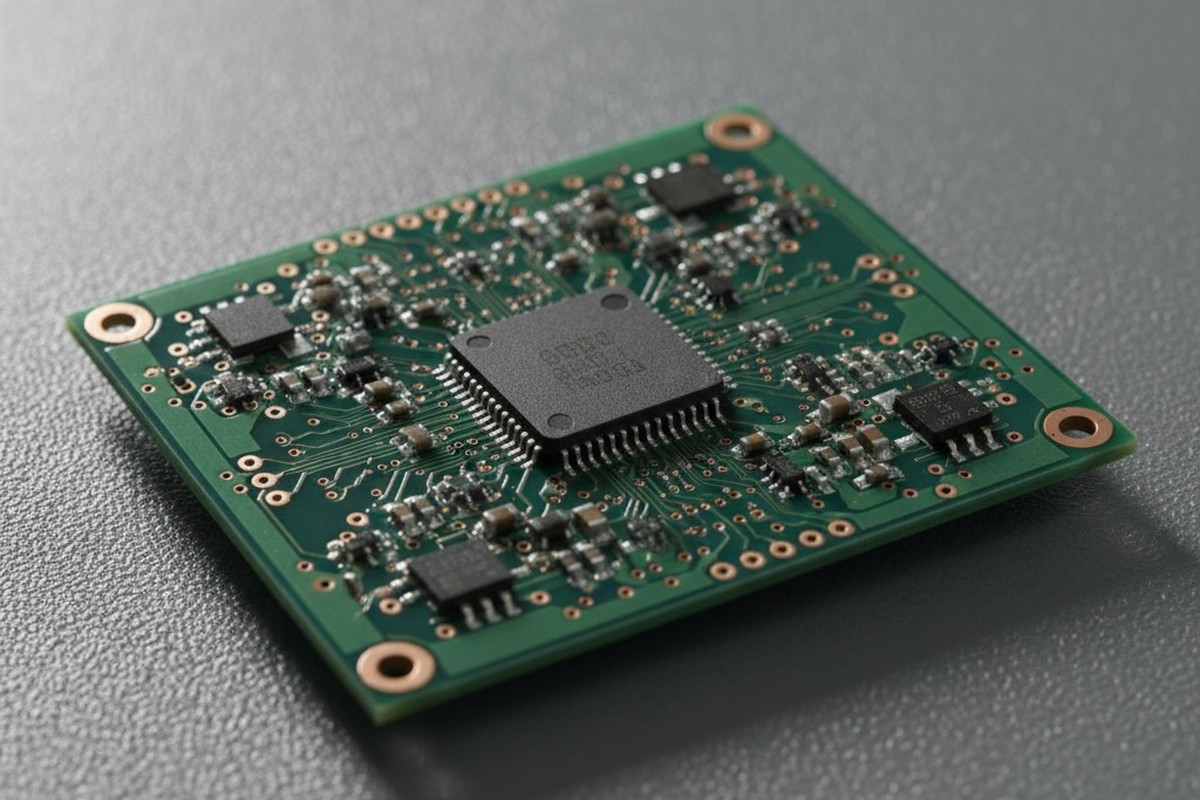

Automotive-Grade PCBA Without the PPAP Drama: A Quality Systems Blueprint

The drama and delays of the Production Part Approval Process (PPAP) are symptoms of a deeper failure in quality planning. This article outlines the essential quality systems blueprint for automotive-grade PCBA, detailing how disciplined APQP, effective control plans, meaningful FMEAs, and non-negotiable traceability are required to meet the stringent reliability and safety demands of the automotive sector, ensuring a smooth path from design to final approval.

-

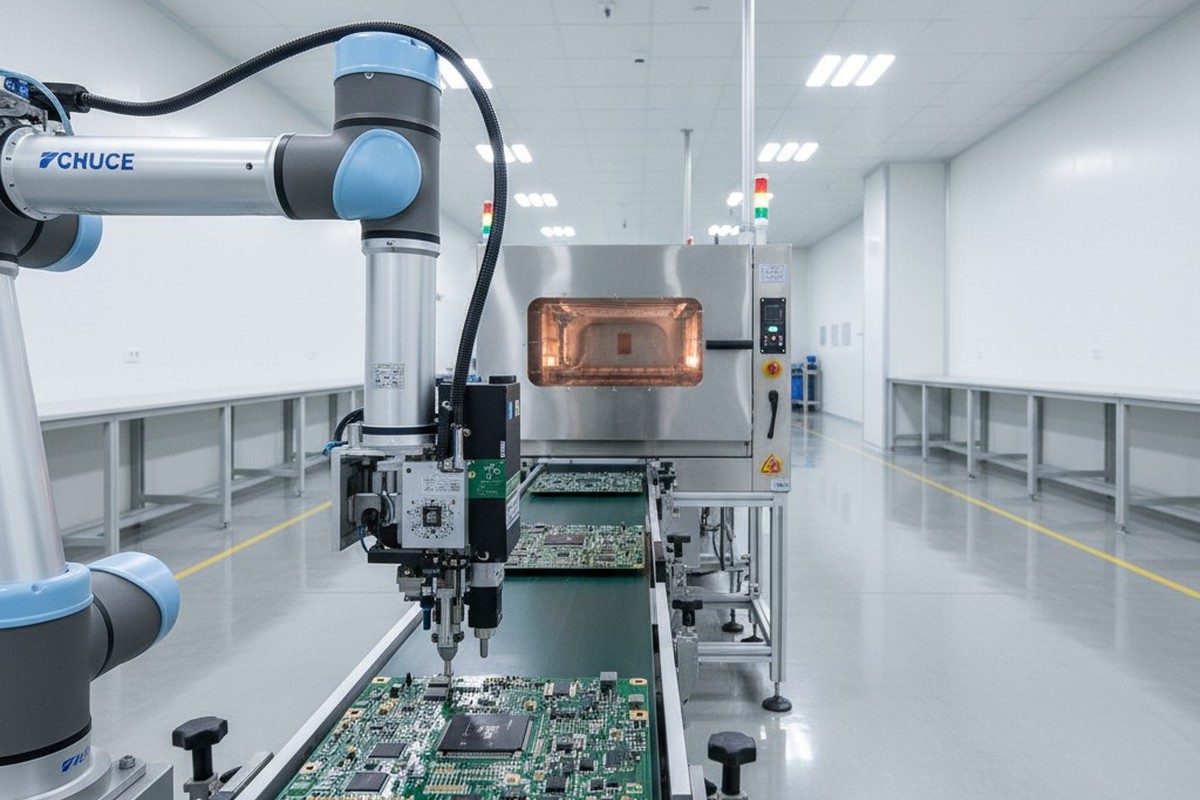

Copper Balance in Reflow: When Thieving Makes Warpage Worse

While copper thieving is a common strategy to reduce PCB warpage, applying it aggressively without considering thermal mechanics can create new, more severe imbalances. This happens because added copper alters thermal mass, leading to asymmetric heating during reflow and causing the very twisting it was meant to prevent.

-

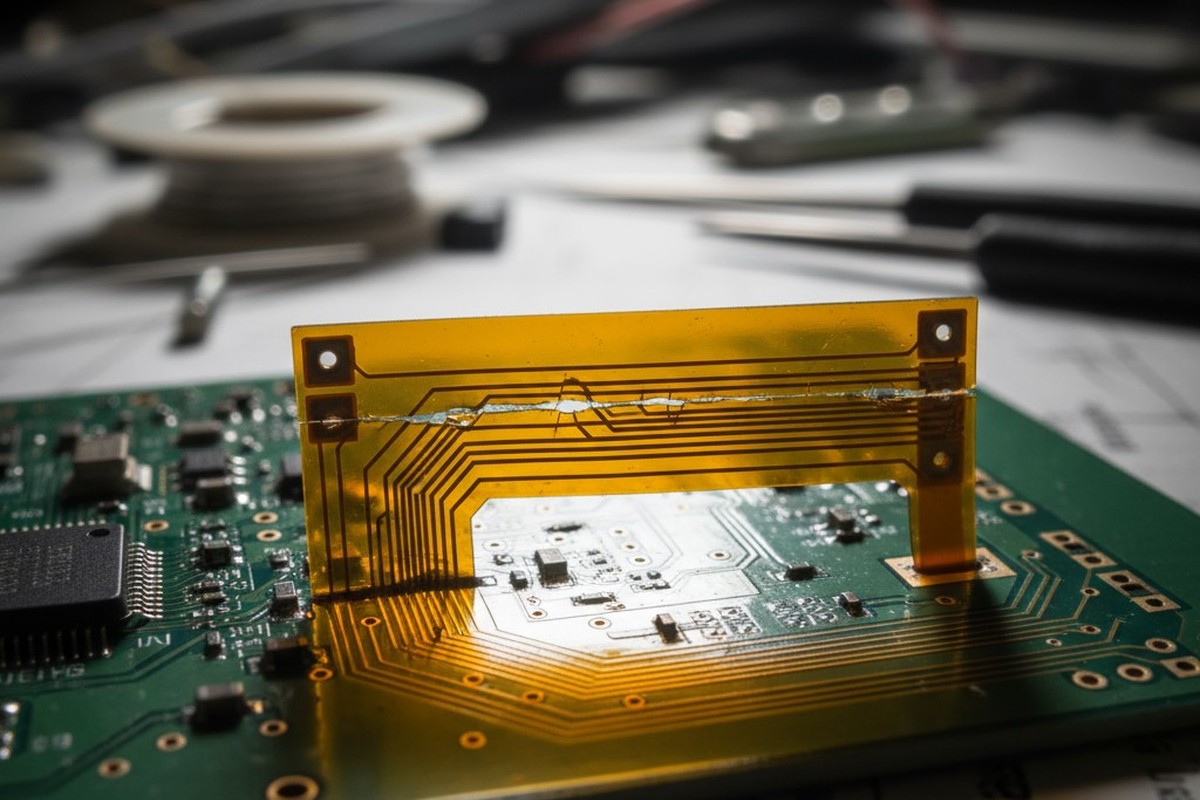

Rigid-Flex That Survives Ten Thousand Bends

A perfect CAD model doesn’t guarantee a rigid-flex circuit will survive thousands of bends in the field. True reliability comes from understanding and controlling four critical physical variables: copper grain direction, trace geometry, coverlay windowing, and stiffener placement. Mastering these interdependent mechanical choices is the key to designing a circuit that endures, not one that fractures prematurely due to copper fatigue.

-

Selective Solder Without Bridges: Hole Design That Actually Works

Stop blaming process control for solder bridges. The root cause of bridging in selective soldering is often baked into the PCB design itself. Incorrect through-hole geometry, poor thermal relief orientation, and inadequate nozzle clearance create conditions where bridges are inevitable. This article explains the physics and provides clear design rules for lead-to-hole clearance and component layout to ensure a reliable, bridge-free manufacturing process.

-

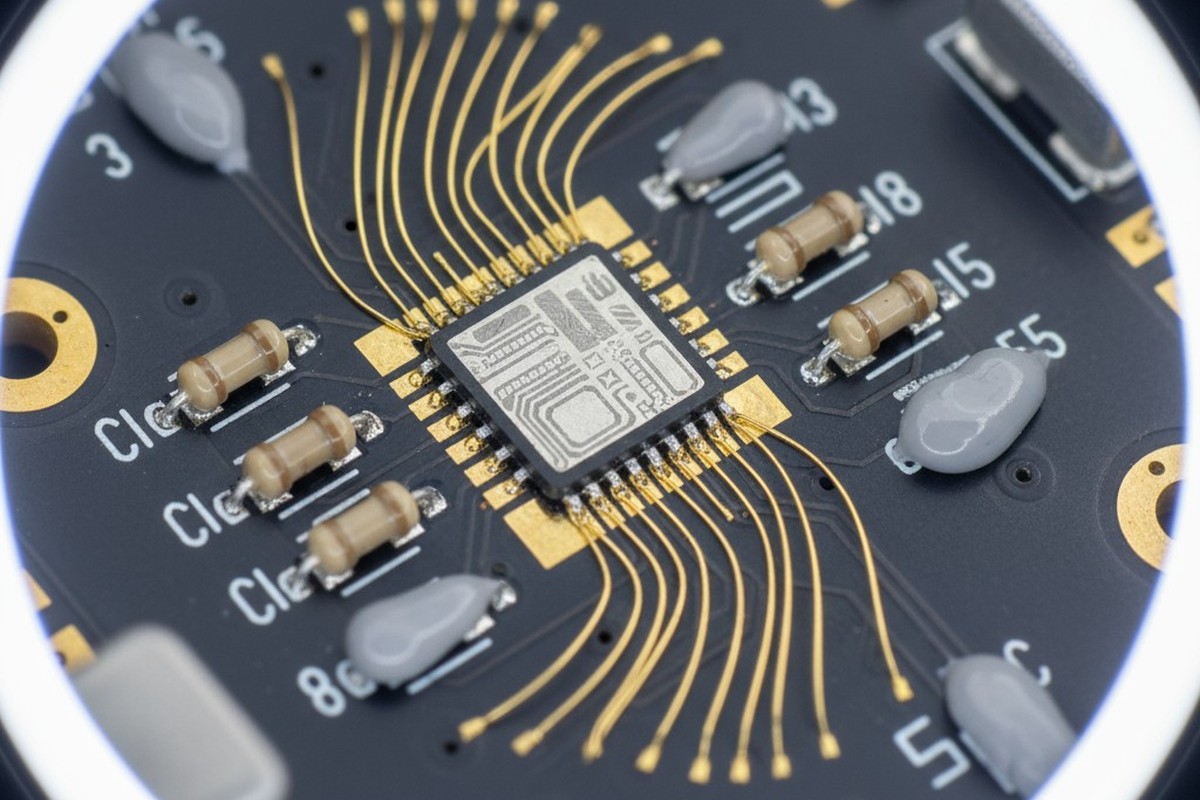

Where ENEPIG Is the Only Sane Choice for Mixed Bond-and-Solder Assemblies

ENEPIG surface finish is the ideal solution for mixed-technology PCB assemblies that require both gold wire bonding and traditional soldering. Its unique multi-layer structure of nickel, palladium, and gold satisfies the conflicting demands of both processes, eliminating the compromises and reliability risks associated with other finishes.