What is Design Rule Check (DRC)

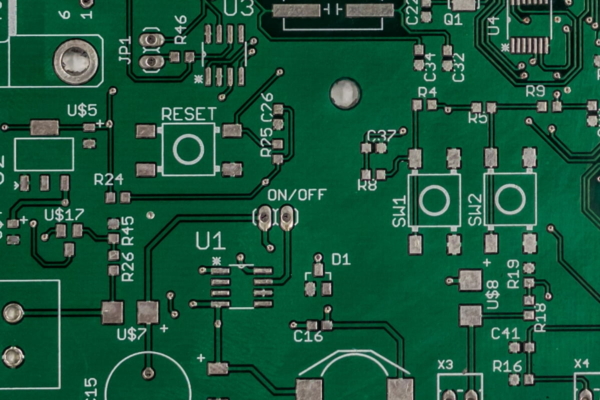

Design rule check (DRC) ensures that a PCB design adheres to specific manufacturing considerations and dimensional tolerances. It involves verifying if the layout of the board aligns with the original circuit diagram or schematic. DRC identifies any violations or errors in the design that may lead to manufacturing issues or failures.

During the DRC process, electronic design automation software is utilized to perform a comprehensive analysis of the design. It checks for deviations from the specified design rules and alerts the designer when a violation occurs. These violations, known as DRC errors, indicate that certain parameters in the design are outside the acceptable range.

By conducting a DRC, designers can ensure that their PCB design meets the necessary requirements for successful manufacturing. It helps to prevent potential problems such as short circuits, incorrect component placements, or inadequate clearances. The DRC helps improve the overall quality and reliability of the final PCB product.

In addition to the DRC, there are other checks and rules involved in PCB design. These include Design for Manufacturing (DFM) rules, which optimize the layout topology to avoid fabrication and assembly issues. Drilling checks ensure the accuracy and quality of drilled holes, including factors like drill-to-copper clearance and annular ring requirements. Signal checks verify key parameters in the Gerber files, while solder mask and silkscreen checks ensure proper isolation and spacing between different surface elements on the PCB.