What is Design Rule Checking (DRC)

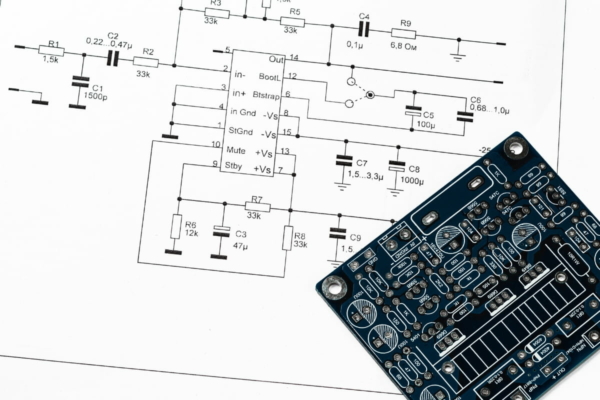

Design rule checking (DRC) ensures the compliance of a circuit board’s schematic and layout with a predefined set of rules and constraints. These rules are established to guarantee that the design meets manufacturing considerations and dimensional tolerances. By performing DRC, designers can identify and rectify potential errors or violations early in the design process, minimizing the risk of manufacturing issues and ensuring the functionality and reliability of the final product.

DRC is a vital step in catching design errors before the manufacturing stage, reducing the need for rework and avoiding costly mistakes. It is typically performed using electronic design automation software, which analyzes the design and flags any violations of the specified rules. These violations, known as DRC errors, indicate areas where the design deviates from the defined parameters.

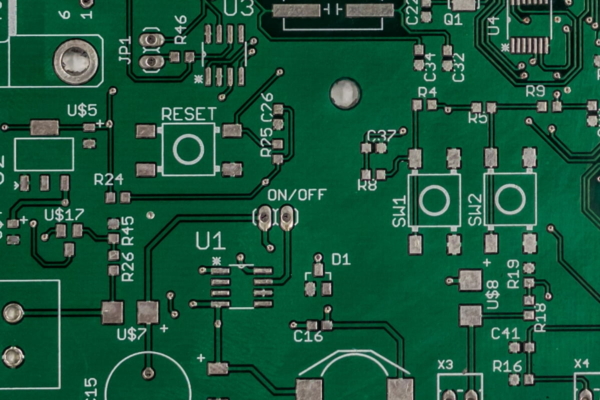

Some common examples of DRC checks include verifying clearance between drilled holes and copper features, ensuring proper annular ring dimensions for reliable connections, validating signal parameters such as conductor width and spacing, checking solder mask isolation, and verifying the spacing of silkscreen markings.

In addition, DRC can also encompass Layout versus Schematic (LVS) checks, which compare the physical implementation of the circuit board with its corresponding schematic to ensure consistency and accuracy. Furthermore, Design for Manufacturing (DFM) rules provide guidelines for optimizing PCB layouts to enhance the manufacturing and assembly processes.