What is Automated Optical Inspection (AOI)

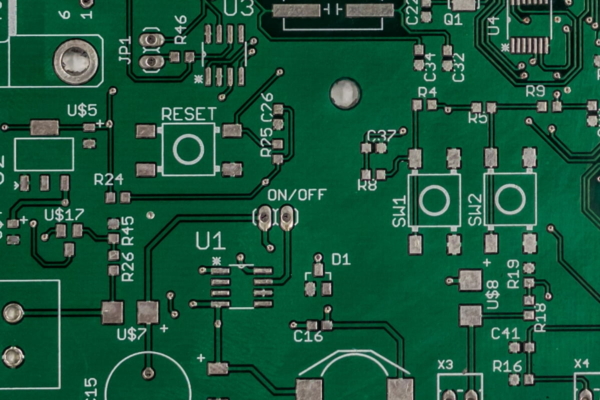

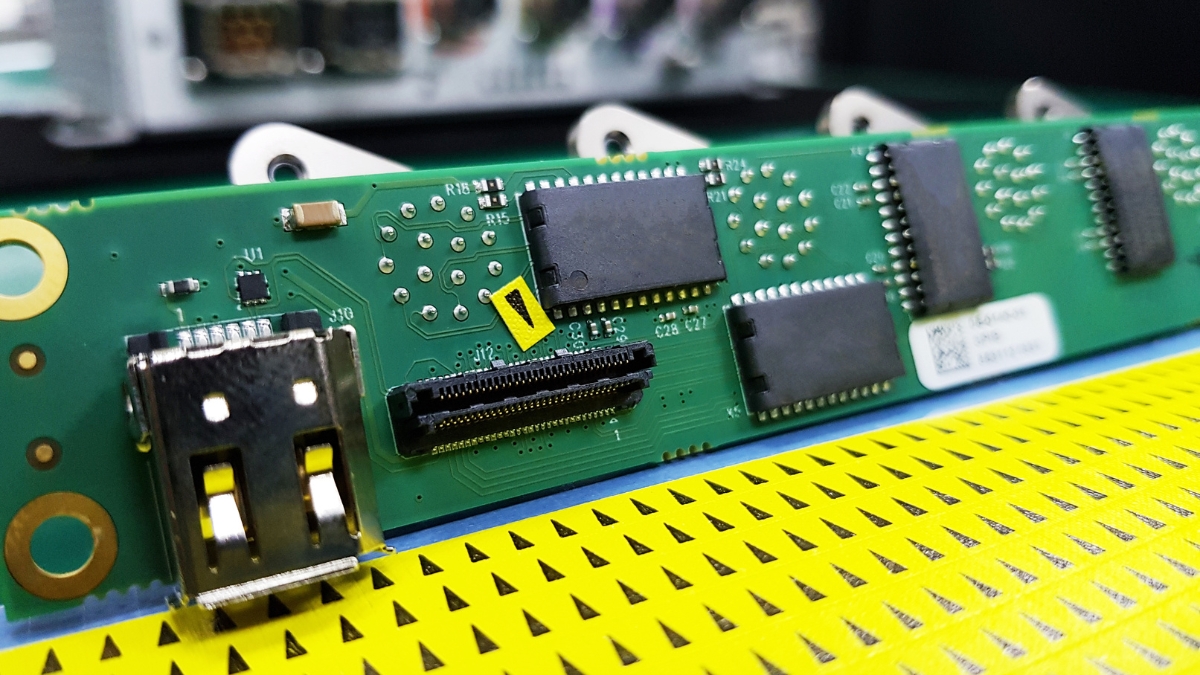

Automated Optical Inspection (AOI) is a visual inspection methodology specifically used in the PCB industry. It is an automated process that utilizes cameras to scan printed circuit board assemblies (PCBAs) and detect defects. AOI is designed to identify two types of failures: catastrophic failures and quality failures.

Catastrophic failures refer to major defects that render the PCBAs non-functional. These can include missing components, such as resistors, capacitors, or integrated circuits. AOI compares the scanned image of the PCBAs with a reference image of the expected component placement to identify these failures.

Quality failures, on the other hand, refer to minor defects that may not render the PCBAs non-functional but can affect their performance or reliability. Examples of quality failures include misshapen fillet or components that are skewed. AOI analyzes the shape, alignment, and orientation of the components on the PCBAs to detect these failures.

AOI is particularly useful in production environments with high volumes and low component variability. It helps ensure the quality and reliability of the PCBAs by quickly and accurately detecting defects. By automating the inspection process, AOI eliminates the need for manual visual inspection, reducing the chances of human error and increasing efficiency.

Frequently Asked Questions

What Is the Process of AOI Inspection

Automated optical inspection (AOI) is a method used to visually inspect printed circuit boards (PCBs), LCDs, and transistors. During AOI, a camera scans the device under test to detect both catastrophic failures, such as missing components, and quality defects, such as incorrect fillet size or shape or component skew. This inspection process is automated and helps ensure the quality and accuracy of the manufactured devices.

What Is AOI Inspection Coverage

Automated Optical Inspection (AOI) is a testing method that involves automated visual inspection of a Printed Circuit Board (PCB). It offers comprehensive coverage by providing inspection of all visible components and solder-joints, ensuring a thorough examination. This technology has been utilized in PCB manufacturing for nearly twenty years.

What Is the Process of AOI PCB

The process of AOI PCB involves utilizing a camera to scan the circuit board and subsequently identifying and flagging any potential defects. This method allows PCB manufacturers to assess the overall quality of the PCB fabrication and provides an opportunity to rectify any errors or flaws that may arise during the fabrication process.

What Is Included in AOI

In the case of corporations, when completing the articles of incorporation, you are required to provide several pieces of information. These include the name of the corporation, its registered address, and DBA name if necessary. Additionally, you must state the purpose of the corporation and indicate whether it is intended to be temporary or permanent.

What Are the Components of AOI

AOI, which stands for Automatic Optical Inspection, is a method used to inspect PCBs during the fabrication process. The setup of AOI typically includes several high-definition cameras with magnification capabilities, a powerful light source, a central processing unit with memory, and an operator.

What Are the Different Types of AOI Machines

There are two main categories of AOI machines available in the market—image-based AOI and algorithm-based AOI. Each type utilizes different technology for the inspection process.

What Are the Disadvantages of AOI

The main drawbacks of AOI solutions include the inability to detect defects that visual inspection may miss, the incapability to identify hidden solder joints, and the failure to detect circuit errors.

Why Do We Need AOI

The AOI machine is equipped with high-resolution cameras and various lighting sources to ensure accurate inspection of the board. It can effectively identify errors such as stains, missing or incorrectly mounted components, and scratches.

What Is Automated Inspection

Automated inspection refers to the utilization of digital or computer-assisted methods for inspecting, measuring, and analyzing components. This automation can involve various processes such as manipulating the object, collecting measurements, or conducting post-inspection analysis to evaluate the component against a given specification.