Blog

-

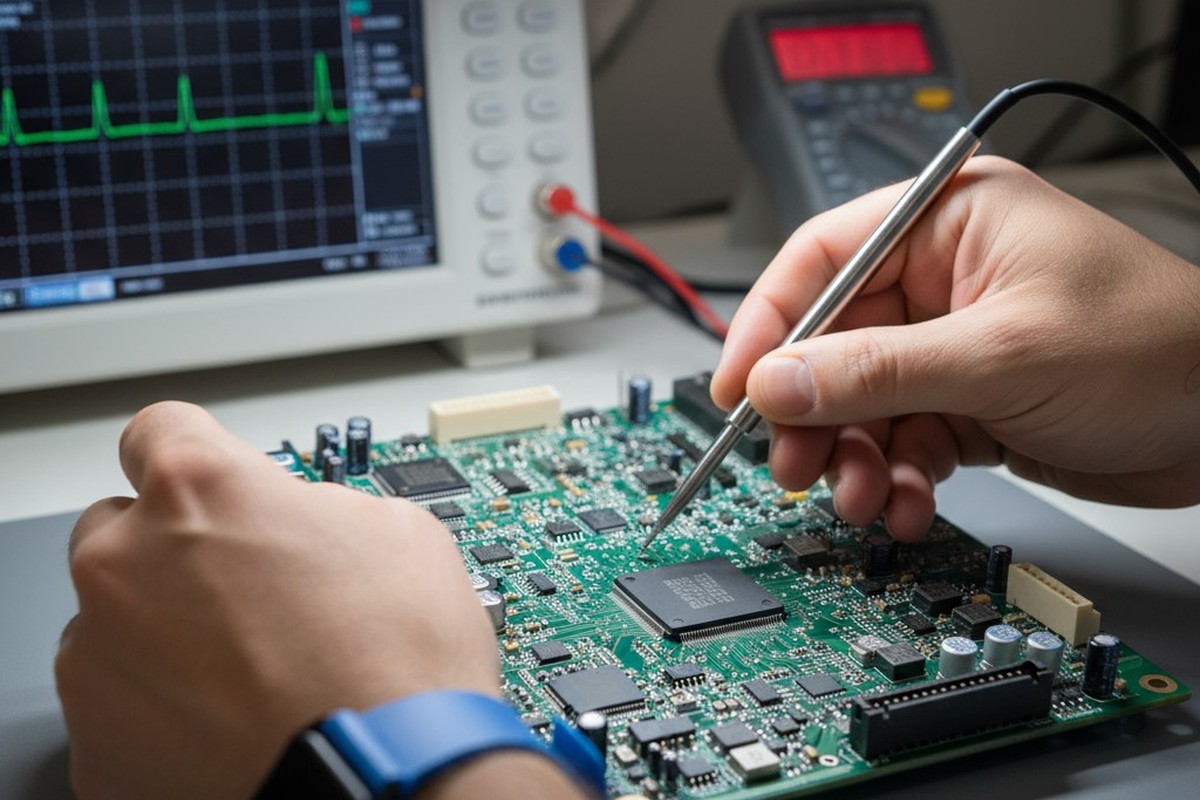

Reflow Profile Myths That Waste a Week on Every NPI

Chasing the textbook ramp-soak-spike reflow profile wastes a week on every new product introduction because it fails on boards with uneven thermal mass. The solution is to abandon guesswork for data-logged profiling, which uses direct component temperature measurements to create a reliable process on the first run, respecting the physics of heat transfer.

-

Taming 800 V: Managing Creepage and Clearance Without Ballooning Board Size

The move to 800V architectures in electric vehicles and industrial electronics creates a design crisis due to increased creepage and clearance requirements, which can balloon board size. The solution involves a multi-faceted approach, combining mechanical slotting, advanced materials, conformal coatings, and disciplined layout to meet safety standards without sacrificing a compact form factor.

-

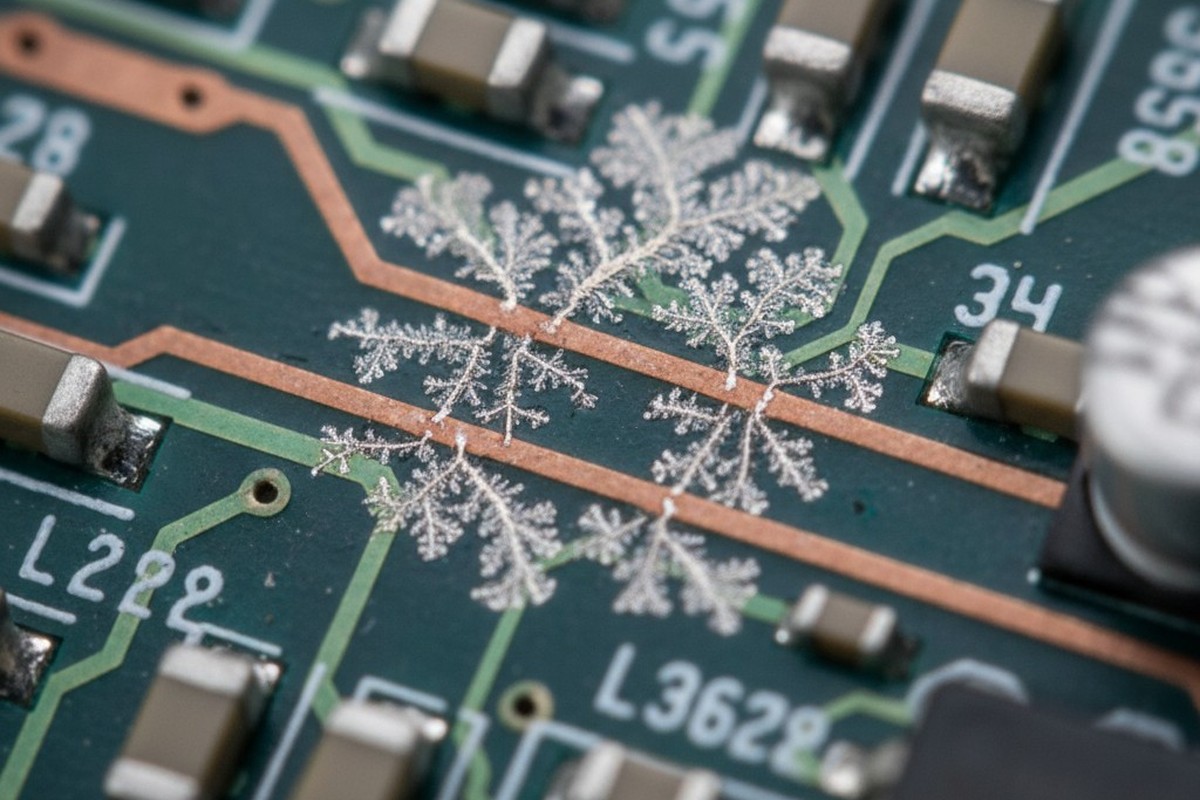

When Conformal Coatings Fail Over No-Clean Flux in Humidity Chambers

Pairing no-clean flux with acrylic or urethane conformal coatings can lead to predictable field failures in humid conditions. Though designed to be inert, the flux residues become electrochemically active when trapped with moisture under the coating, accelerating corrosion and dendritic growth instead of preventing it.

-

Test Coverage That Pays Back: Boundary Scan Plus Vectorless Over Full ICT for Low Runs

While full in-circuit testing (ICT) is the gold standard for high-volume production, its steep fixture costs and long lead times are prohibitive for low-volume runs. For production under 300 units, a smarter strategy combines boundary scan, vectorless testing, and functional tests to achieve excellent fault coverage without the economic and logistical burden of custom fixtures, enabling faster, more flexible manufacturing.

-

Right-Sizing Lot Traceability for Medical Assemblies

Over-investing in lot traceability for medical assemblies creates the illusion of control without proportional risk reduction. The key is to calibrate traceability depth based on risk, matching the system’s granularity to the consequences of failure. This ensures a defensible, efficient system that enables targeted action during a recall without stalling production or burying teams in data noise.

-

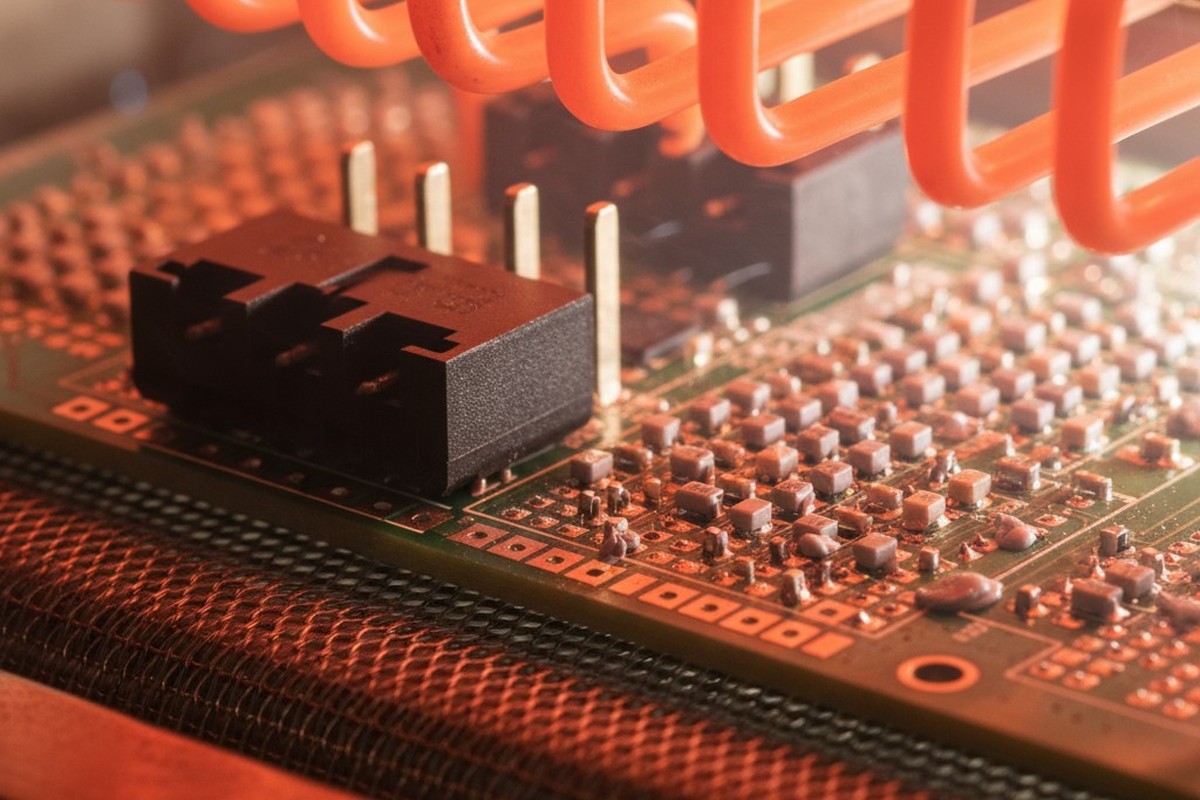

Micro-BGA Yields at Bester PCBA: Driven by Vacuum Reflow and Better Paste

At Bester PCBA, we solve the challenge of micro-BGA assembly by moving beyond conventional methods. Our systematic approach integrates vacuum reflow to eliminate voiding, precision stencil design for accurate paste deposition, and specialized solder paste to achieve consistent, sub-one-percent defect rates, engineering quality directly into the process.