Modern electronic products are built using printed circuit boards (PCBs). These consist of conductive tracks and other electronic features formed from copper sheets and embedded on a non-conductive substrate. To cater to the growing demand for these boards, PCB manufacturers in China utilize the latest technologies to produce them efficiently.

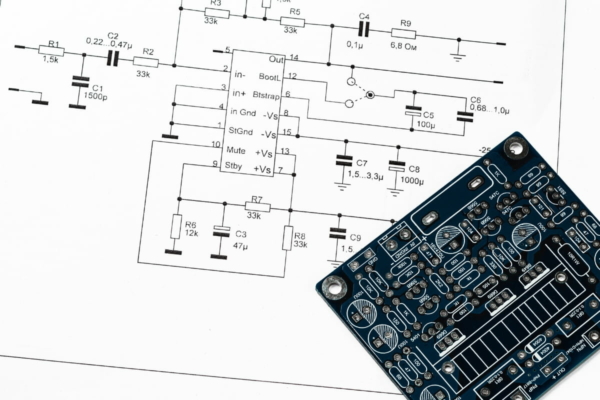

Design of PCB

Before the desired PCB is produced, an appropriate design is essential. Manufacturers in China employ electronic design automation tools to capture the required design. This process determines the optimal placement of components on the board. Power planes are then identified, through which interconnections for signals are traced. The components are strategically placed to facilitate the production of Gerber files that represent the complete design. The use of advanced software ensures precision in the layout and helps in predicting potential issues early in the design phase, thereby reducing the risk of costly revisions later.

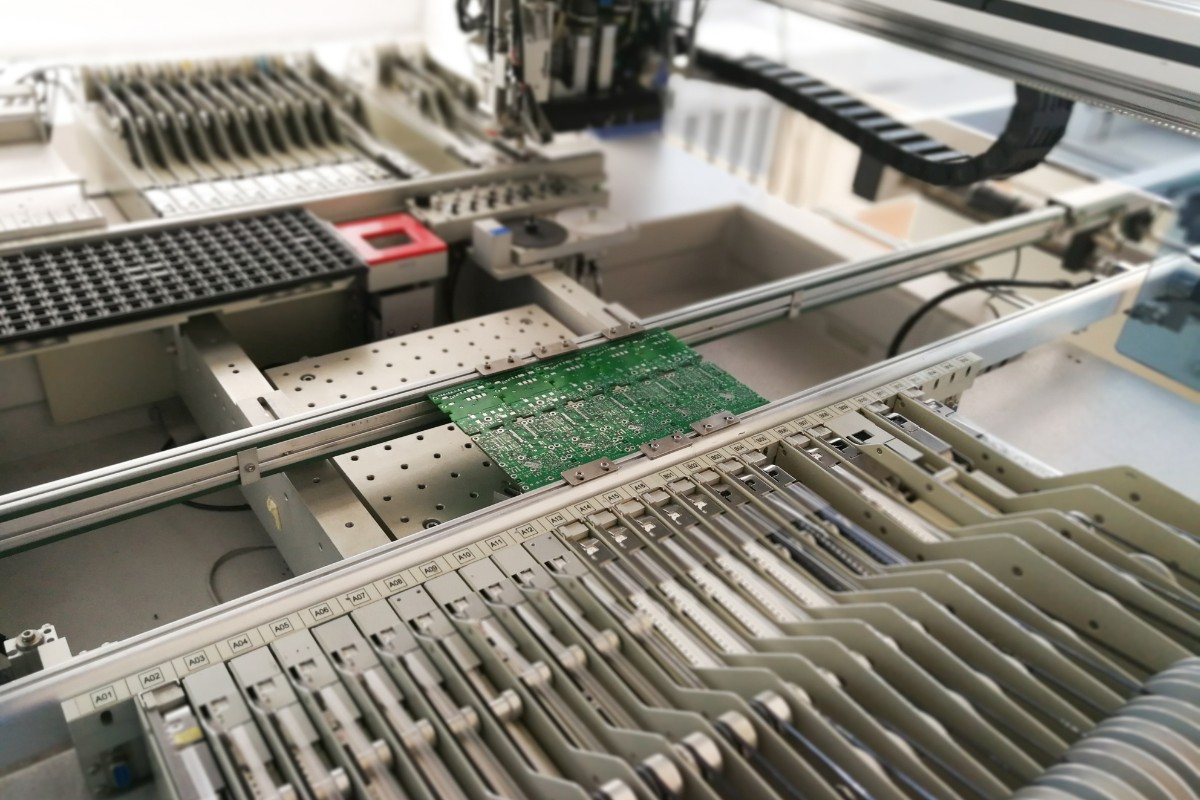

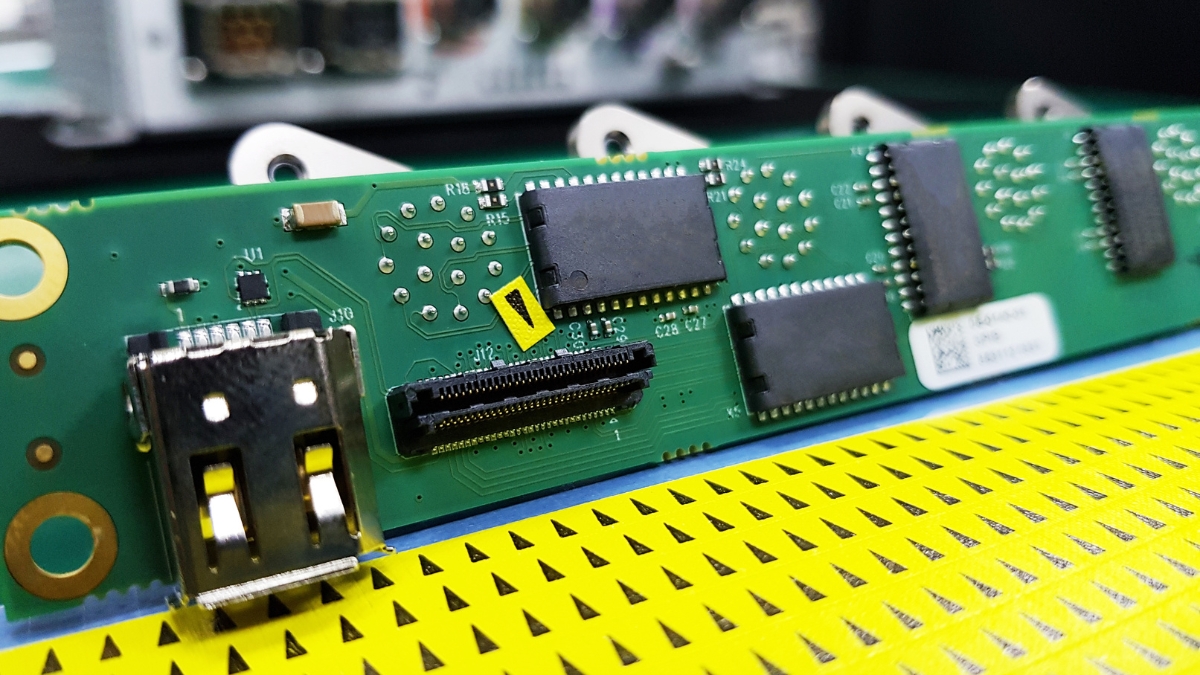

Manufacture of the Boards

Once a design is finalized, the manufacturing process commences. This may take various forms depending on the resources available to the manufacturer. It is followed by the assembly of selected components and rigorous testing. It is crucial to note that testing at this stage is conducted to ensure there are no open circuits on the board or short circuits that could impair the performance of the completed electronic product. Adequate packaging with protective measures is then implemented to ensure there are no breakages or malfunctions that may occur during shipping. The materials used in the boards are chosen based on their performance characteristics and compliance with international environmental standards, ensuring both durability and sustainability.

Fast Production of Boards

As technology evolves rapidly, it is imperative that electronic product designs are produced swiftly to maintain their relevance in the market and fulfill their intended functions. Manufacturers always ensure timely delivery of any order, which can range from 24 hours to two weeks depending on the design complexity and the logistics involved in the shipment process.

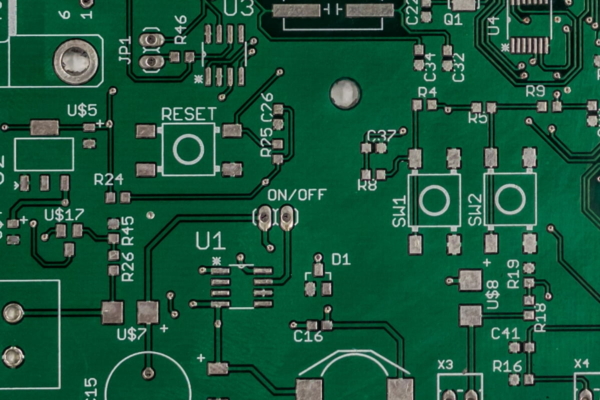

Customized Designs

The circuit design on a PCB can vary significantly. For this reason, manufacturers in China ensure that the provided design specifications are adhered to meticulously. This adherence allows for better control over the product design and the final production of the required electronic device, ensuring that each unit meets the specific needs of the client.

Access to Design Software

Designing a PCB is a complex and time-consuming process that requires precision. Manufacturers provide access to sophisticated design software, which offers a platform for making direct orders. This software not only facilitates faster communication with the manufacturer but also provides assistance during the design phase. It includes an inbuilt calculator that delivers an instant quote for the required design, enabling the designer to prepare an appropriate budget and make decisions that expedite delivery.

Get the Exact Quantity Required

The number of boards needed can vary at different stages of production. Initially, only a few boards may be necessary, while larger quantities are required as full production of the electronic equipment progresses. Manufacturers offer the flexibility to specify the exact number of units needed, thus ensuring there is no excess production that could increase costs and lead to waste.

Full-Time Customer Support

During production, clients are often keen on the developments and may require guidance and updates. PCB manufacturers in China ensure that a support team is always available to address any queries that may arise during the production process. The technical team provides assistance in designing appropriate boards and offers timely updates on the progress and shipment process, ensuring deliveries are made as scheduled.

Getting the Best Quotes from Manufacturer

Cost is a critical consideration in production. The cost of PCBs significantly influences the overall cost of the final electronic product. Obtaining the best quotes is crucial for managing the production budget effectively, as this will enable better pricing once the product is launched in the market. Upon placing an order, the manufacturer prepares a detailed quote considering factors such as the type of boards required, the production costs, and the urgency of delivery. These considerations guide the best approach and provide advice on possible alternatives to achieve higher quality boards at a lower cost. Following a consensus, the manufacturer issues the final quote, which forms the basis for the production contract, stipulating agreed terms including costs and delivery timelines.

Quality Assurance and Control

Ensuring the quality of PCBs is paramount throughout the manufacturing process. Manufacturers implement stringent quality control measures at each stage, from the initial material selection to the final testing of the boards. This rigorous approach guarantees that each PCB meets the highest standards of quality and functionality.

Environmental Impact

PCB manufacturers in China are increasingly aware of their environmental responsibilities. They adopt eco-friendly practices throughout the manufacturing process, including the use of recyclable materials and the implementation of waste management strategies. These practices not only comply with international environmental standards but also appeal to eco-conscious consumers.

Innovation and R&D

Continual innovation and research and development (R&D) are key to staying competitive in the PCB manufacturing industry. Manufacturers invest in R&D to explore new materials, techniques, and technologies that enhance the performance and reduce the costs of PCBs. These innovations pave the way for the next generation of electronic products, ensuring that manufacturers remain at the forefront of the industry.

By addressing these additional sub-topics and expanding on the existing ones, the article provides a comprehensive overview of PCB manufacturing in China, highlighting the industry’s commitment to quality, efficiency, and sustainability.