What is Design for manufacturing (DFM)

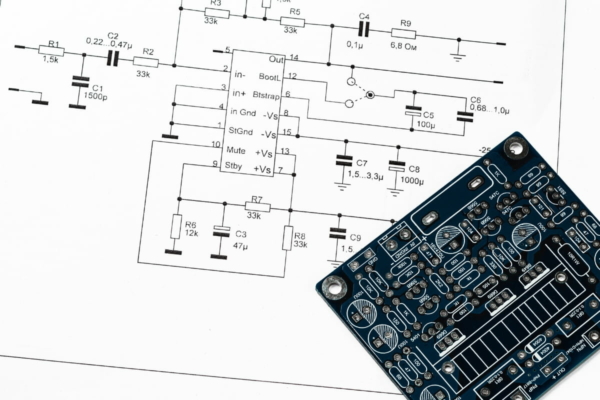

Design for manufacturing (DFM) is a methodology to optimize the design of a product for efficient and cost-effective manufacturing. It involves analyzing various aspects of the design, such as dimensions, materials, tolerances, and functionality, to identify potential issues or inefficiencies that could arise during the manufacturing process. The primary objective of DFM is to streamline the manufacturing process by eliminating or minimizing design elements that could lead to difficulties or delays in production.

DFM encompasses several considerations, including design simplification, component selection, design for assembly (DFA), design for testability (DFT), material selection, tolerance analysis, and design for cost. Design simplification involves reducing complexity and minimizing the number of manufacturing steps required, resulting in a more efficient and cost-effective process. Component selection focuses on choosing readily available, cost-effective components that are compatible with the manufacturing processes being used.

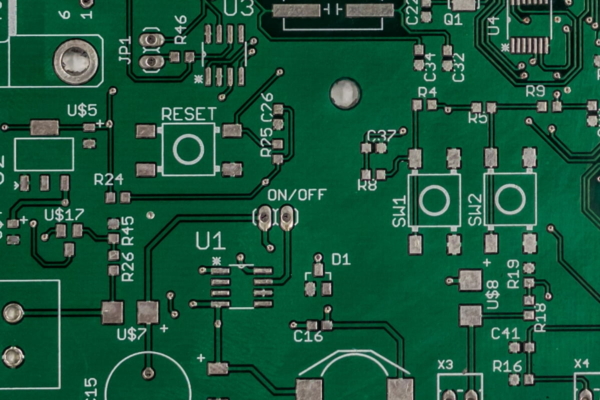

DFA is a subset of DFM that optimizes the design for ease of assembly, ensuring components and features are easy to handle, align, and connect during the assembly process. DFT, another subset of DFM, focuses on designing the product to facilitate testing and inspection, incorporating test points, access points, and built-in test features.

Material selection in DFM considers choosing materials that are readily available, cost-effective, and compatible with the required manufacturing techniques. Tolerance analysis involves analyzing and optimizing the specified tolerances to ensure they are achievable and do not result in excessive scrap or rework. Design for cost aims to optimize the design for efficient manufacturing, minimizing production costs, waste, and improving profitability.

DFM bridges the gap between design and manufacturing by considering manufacturing constraints and requirements during the design phase. By doing so, it ensures that the final product can be manufactured efficiently, cost-effectively, and with high quality.