What is Electroplating

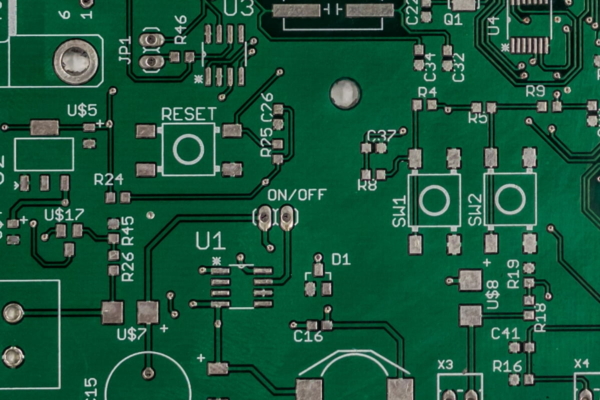

Electroplating is a process used to apply a layer of metal onto the surface of a PCB or specific areas of the board. This procedure involves immersing the PCB in an electrolyte solution and utilizing an electric current to transfer metal ions from the anode to the cathode (the PCB). As a result, a thin layer of metal is deposited onto the surface, enhancing the PCB’s conductivity, durability, and appearance.

The electroplating process is computer-controlled and utilizes electrolysis to facilitate the transfer of metal ions. The duration of the process depends on the desired thickness of the metal layer. To ensure even distribution of the metal on the surface, the conductive pattern of the PCB plays a crucial role. In some cases, an additional copper grid may need to be applied.

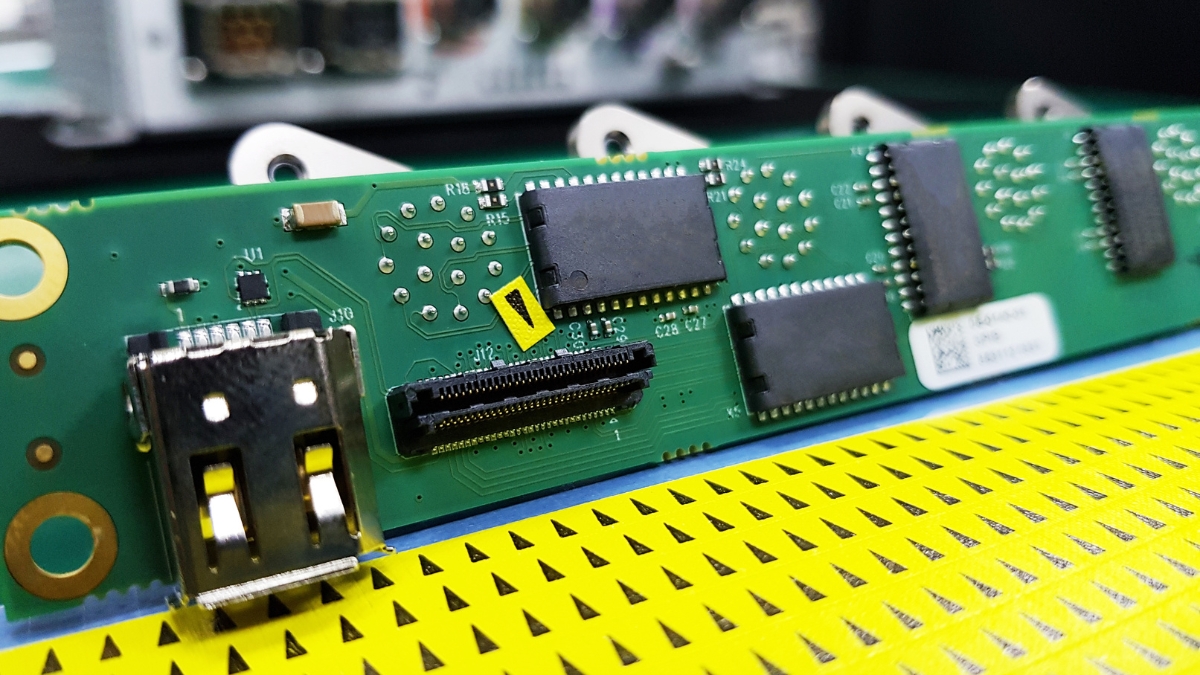

In addition to enhancing conductivity, electroplating can serve various purposes in the PCB industry. It can create conductive traces on the surface of the board, protect exposed copper traces from oxidation, improve solderability, and provide a protective coating against environmental factors. Electroplating is particularly useful for through-hole vias and surface traces.

Furthermore, the electroplating department in the specific context of Unimicron also handles the application of final surfaces. This includes processes such as chemical tin, chemical nickel/gold, HASL (Hot Air Solder Levelling), and external processes like chemical nickel/palladium/gold, hard gold, and OSP (Organic Solderability Preservative).