What is Laser soldering

Laser soldering is a technique to selectively heat solder using laser irradiation. This process involves using a direct diode laser to generate heat and create a bond between two parts.

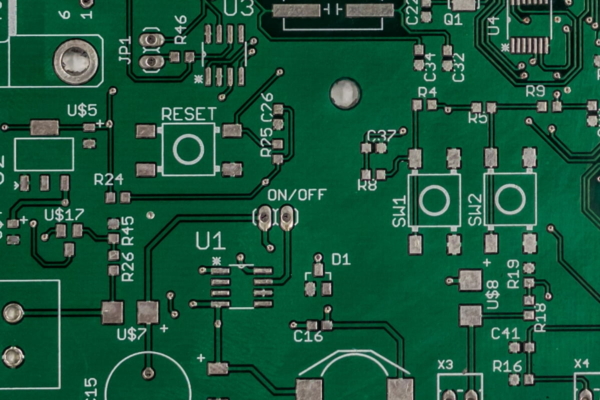

Laser soldering can provide localized and selective heat input. Unlike traditional soldering methods, laser soldering only heats the specific areas that require soldering, while leaving the surrounding components unaffected. This is particularly beneficial for heat-sensitive components that may be damaged by excessive heat.

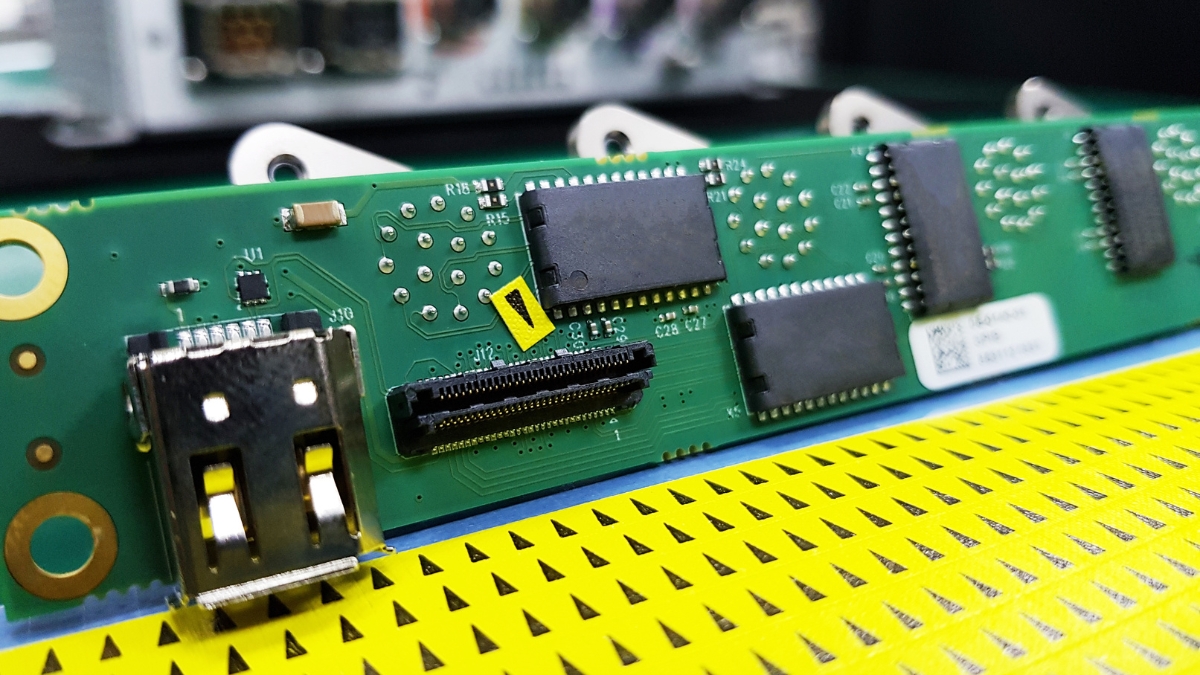

Another advantage is its high precision. The laser beam can produce spot sizes on the order of hundreds of microns, allowing for precise control and accurate soldering. This level of precision is crucial in the PCB industry, where small and intricate connections need to be made.

Laser soldering also offers fast control of heat input. The laser can be turned on and off rapidly, enabling quick and efficient soldering. This is especially advantageous in high-volume production environments where speed is essential.

Additionally, laser soldering is a non-contact process, meaning that the soldering can be performed without physical contact between the soldering tool and the components. This eliminates the risk of mechanical stress or damage to the components and reduces the likelihood of contamination.

Furthermore, laser soldering provides efficient and homogeneous heat input. The laser beam can evenly distribute heat across the solder joint, ensuring a consistent and reliable bond. This is crucial for achieving high-quality solder connections.