Blog

-

The Anatomy of an Outgassing Volcano: Why Via-in-Pad Requires Type VII Caps

Placing a via inside a component pad creates a pressure vessel that can “volcano” during reflow, causing catastrophic assembly defects. This guide explains why common tenting methods fail and how specifying IPC-4761 Type VII (Via-in-Pad Plated Over) is the only reliable engineering solution to prevent outgassing and ensure a reliable solder joint.

-

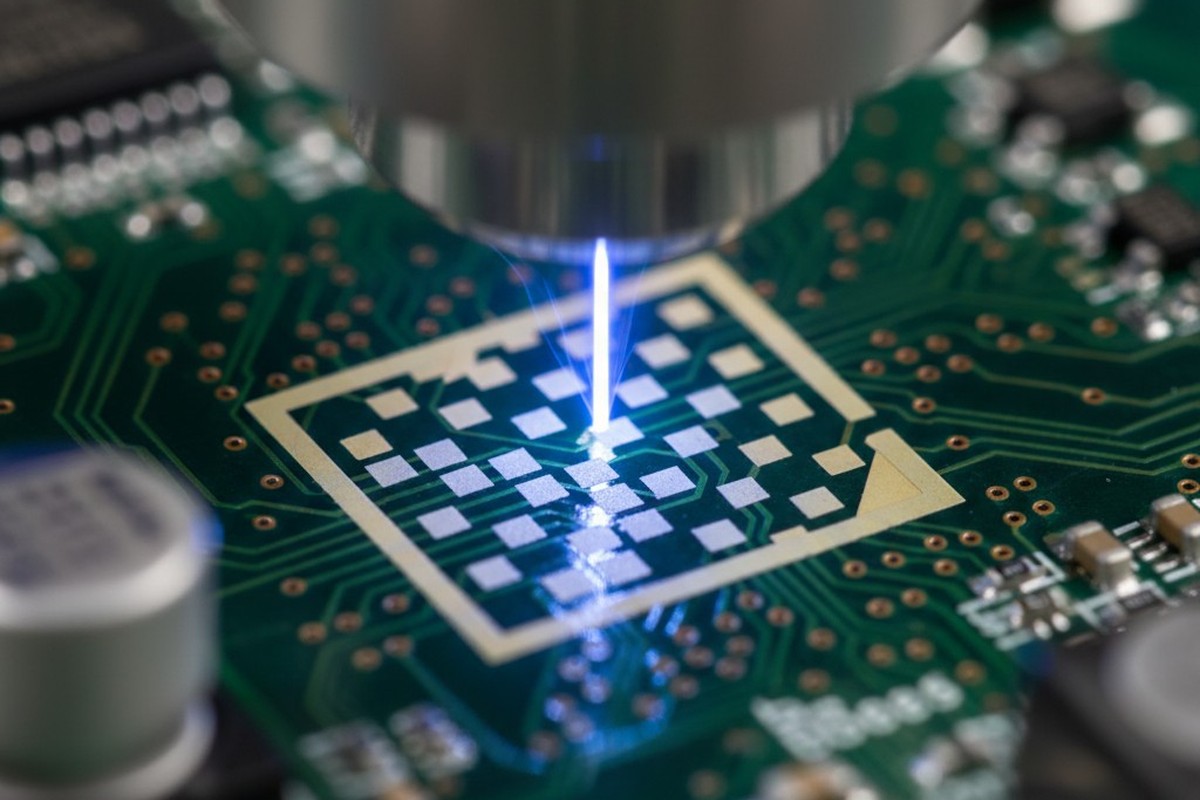

The Permanence of the Mark: Why Laser Ablation is the Only Real Traceability

When ink or label-based serial numbers wash away during manufacturing or degrade in the field, your product’s audit trail is lost forever. Laser ablation, a process that removes material rather than adding it, is the only truly permanent solution for PCB traceability that survives the harsh SMT process.

-

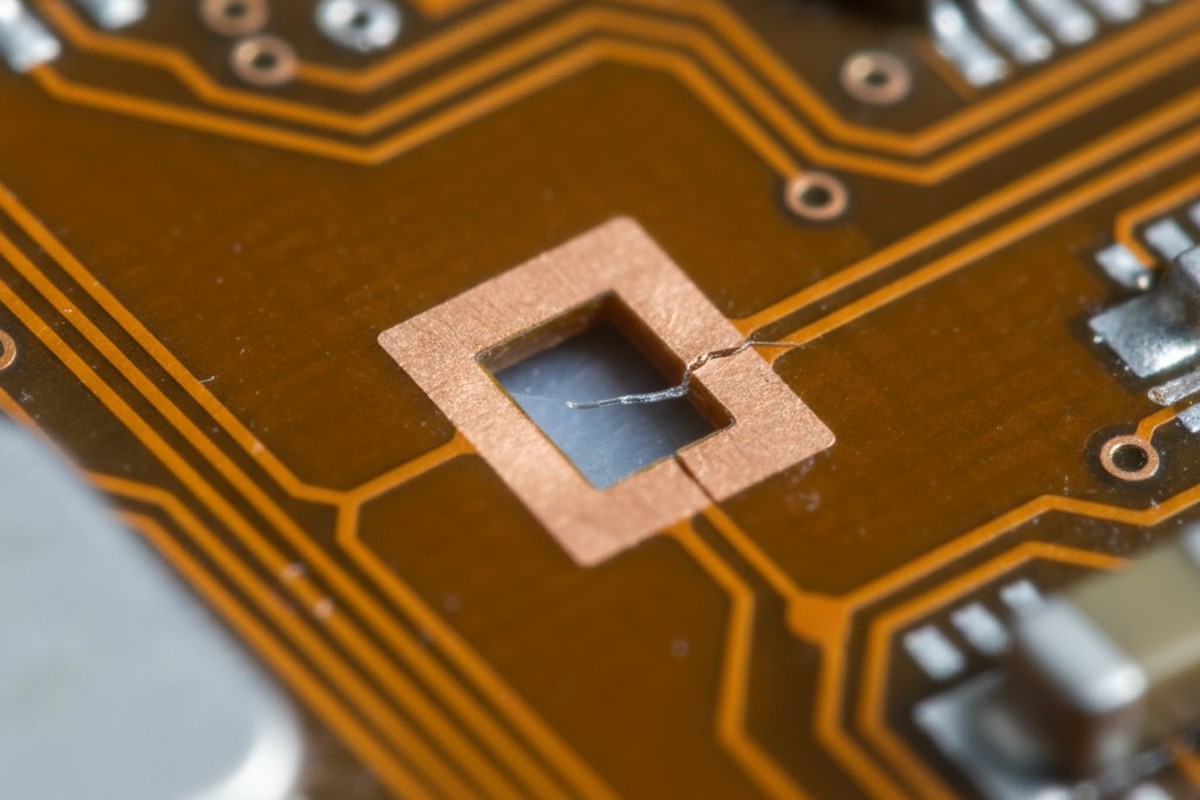

Flex PCB Coverlay Openings That Do Not Stress the Copper

Sharp, 90-degree corners in flex PCB coverlay openings look precise but create massive stress risers that lead to cracked copper traces. Proper design requires radiused corners and oversized openings to account for adhesive flow, preventing catastrophic field failures.

-

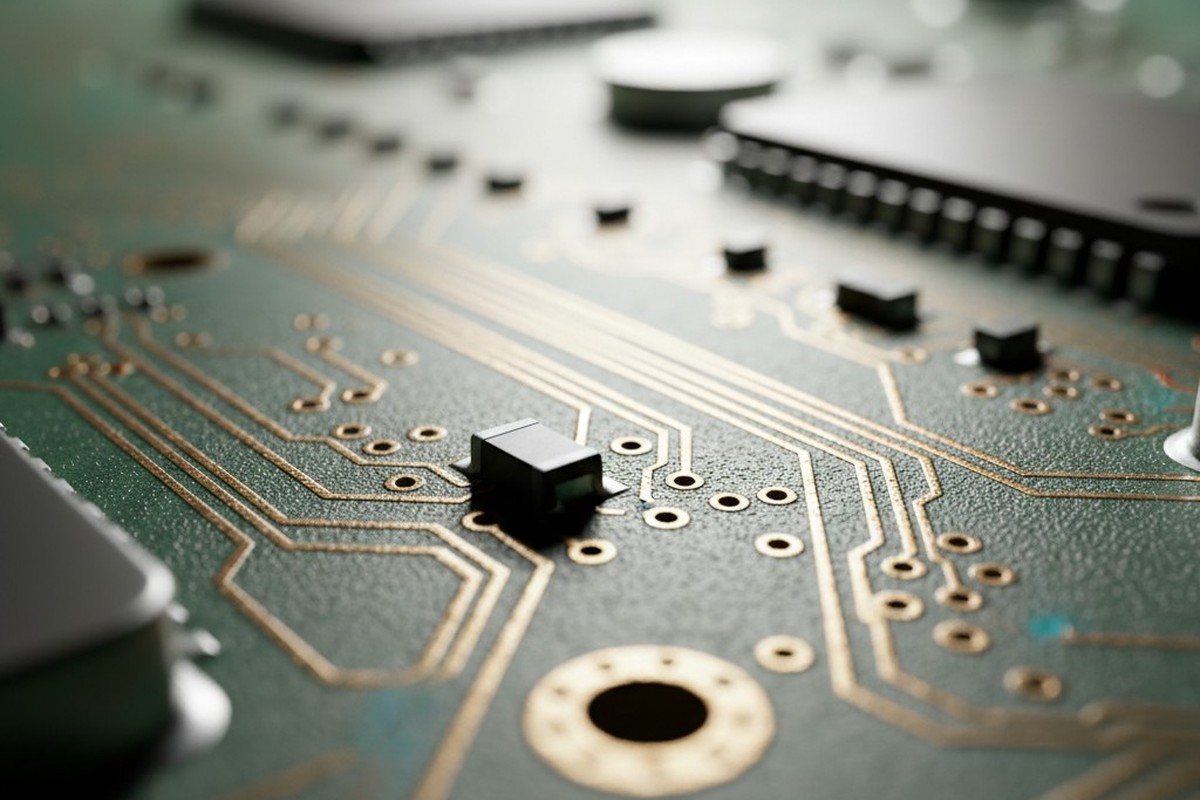

The Signal-to-Noise Ratio of Your PCB Build

Traditional PCB fabrication workflows fail due to communication breakdowns, where non-technical brokers cause massive delays. By enabling direct access between designers and CAM engineers, you can resolve issues in minutes instead of days, eliminating administrative dwell time and ensuring your project stays on schedule.

-

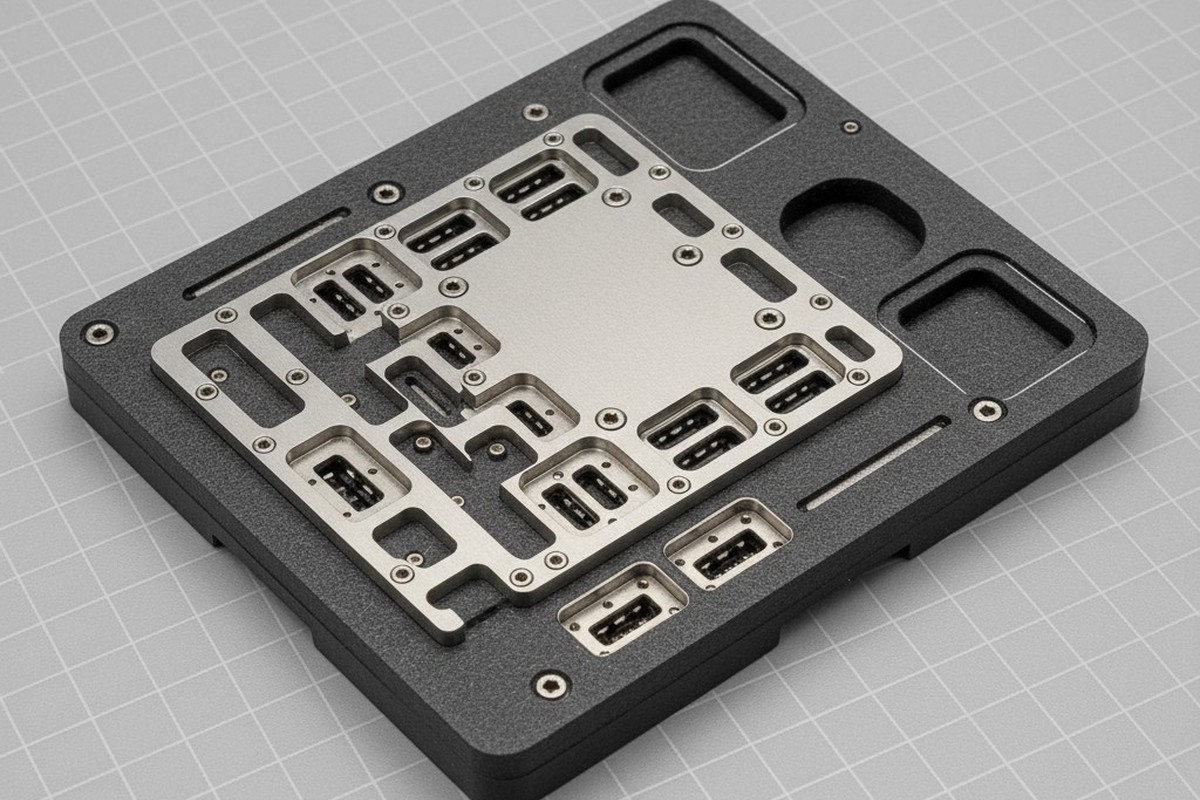

The Hidden Physics of Custom Wave Pallets

When odd-form components threaten manufacturing speed, selective soldering is often a trap. Custom wave solder pallets, designed with a deep understanding of fluid dynamics and material science, are the key to converting a slow serial process back into a parallel one, maximizing throughput.

-

The Throughput Trap: Why Flying Probes Kill Volume Production

Relying on flying probe testers for mass production seems like a clever way to avoid high upfront fixture costs, but it’s a trap. This common mistake creates a critical throughput bottleneck that slows your entire production line, inflates unit costs, and ultimately costs far more than the bed-of-nails fixture you tried to avoid.