Blog

-

The Silent Killer of Yield: Why Your MLCCs Keep Cracking (And It’s Not the Placement Machine)

When MLCCs crack and yield drops, don’t blame the pick-and-place machine. The true cause is almost always board flex during depaneling, which creates a telltale 45-degree crack signature that can lead to field failures long after the board passes factory tests.

-

The Physics Don’t Lie: Counterfeit Detection Beyond the Label

Visual inspection is no longer enough to stop sophisticated counterfeit components. To protect your supply chain, you must go beyond the label and use V-I curve tracing to interrogate the physics of the device and verify its authenticity against a known golden unit.

-

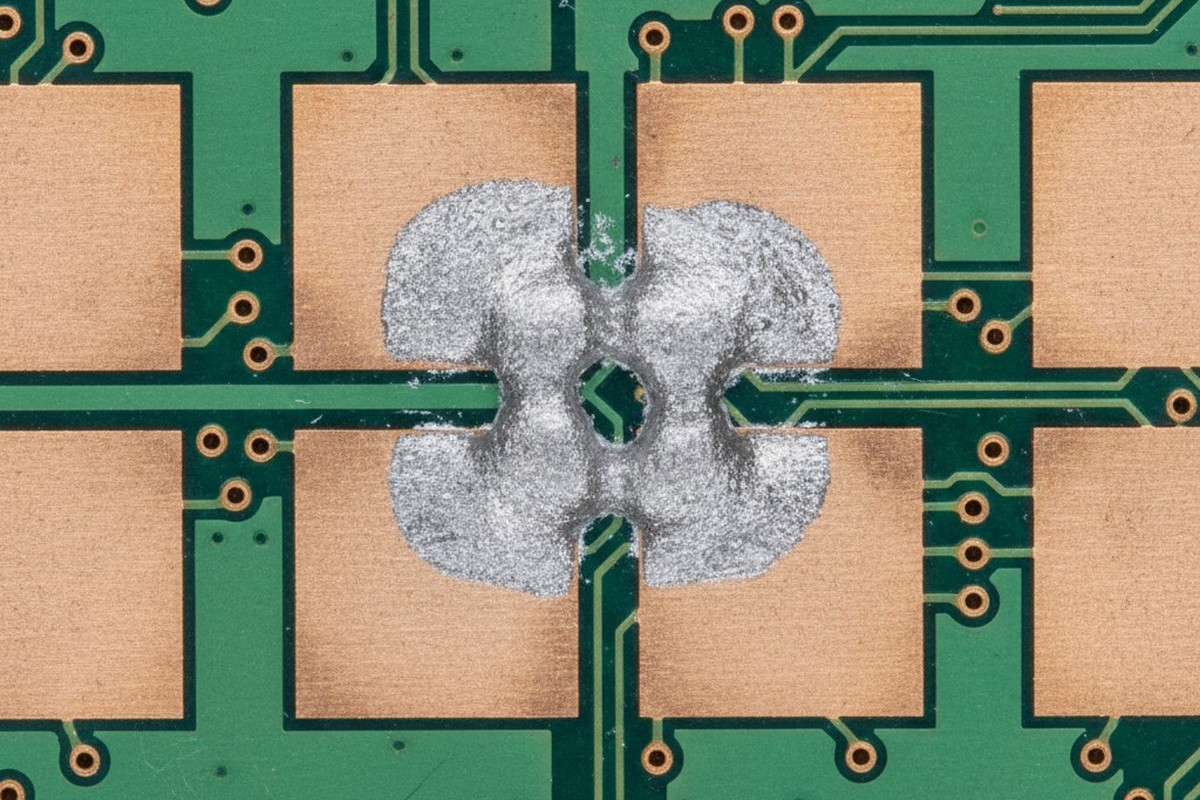

The Invisible Gap: Why Your Paste Fails Before the Oven

Many SMT defects like bridging and voiding are blamed on the reflow oven, but the root cause is often cold slump—the solder paste spreading and collapsing at room temperature due to poor handling and environmental moisture. This invisible failure happens long before the board sees any heat.

-

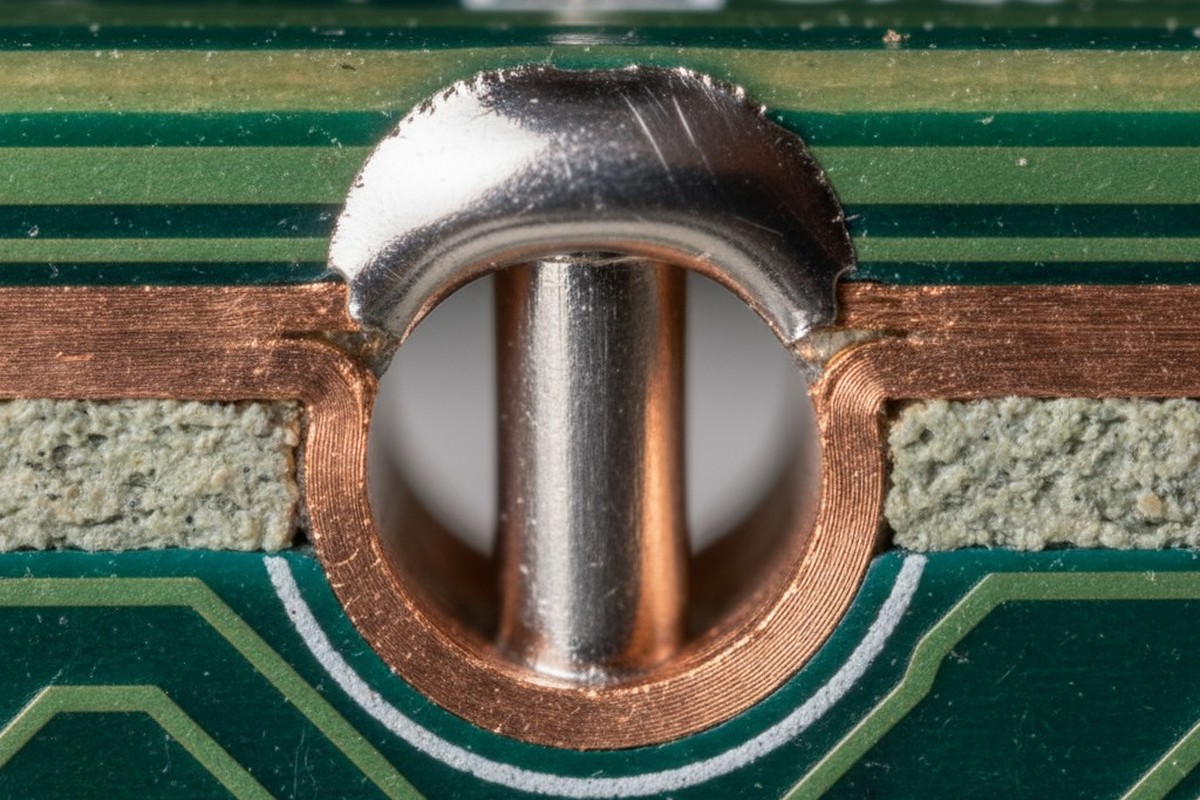

Physics Doesn’t Negotiate: Why IPC Class 3 Vertical Fill Fails Inside the Barrel

A perfect top-side fillet doesn’t guarantee a solid solder joint inside the barrel for IPC Class 3 assemblies. Poor vertical fill often results from design flaws like an incorrect hole-to-lead ratio causing gas lock, or insufficient pre-heating that allows the PCB to act as a heat sink, freezing the solder prematurely.

-

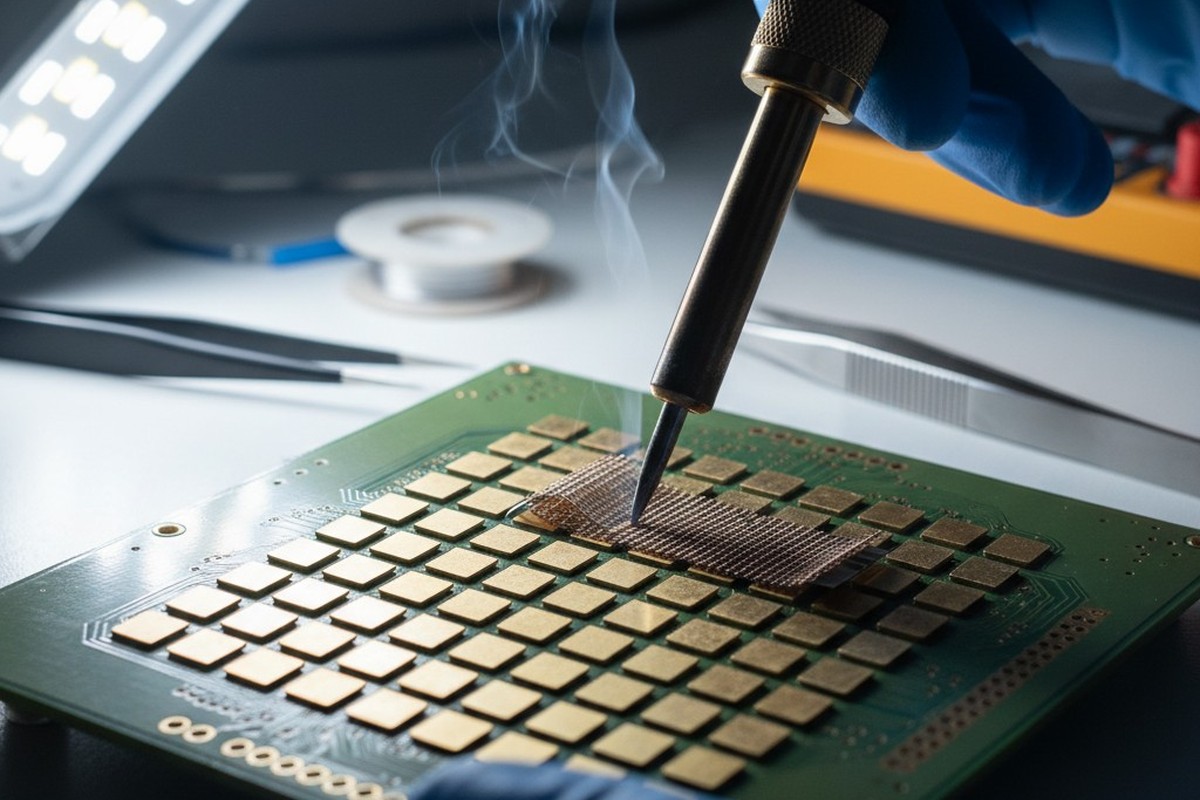

Saving the Silicon: The Economics and Physics of FPGA Rework

When a prototype with a high-end FPGA fails, rework is a high-stakes salvage operation. This process demands a deep understanding of thermal physics to avoid destroying the board, turning a simple repair into a complex engineering challenge where the entire project is at risk.

-

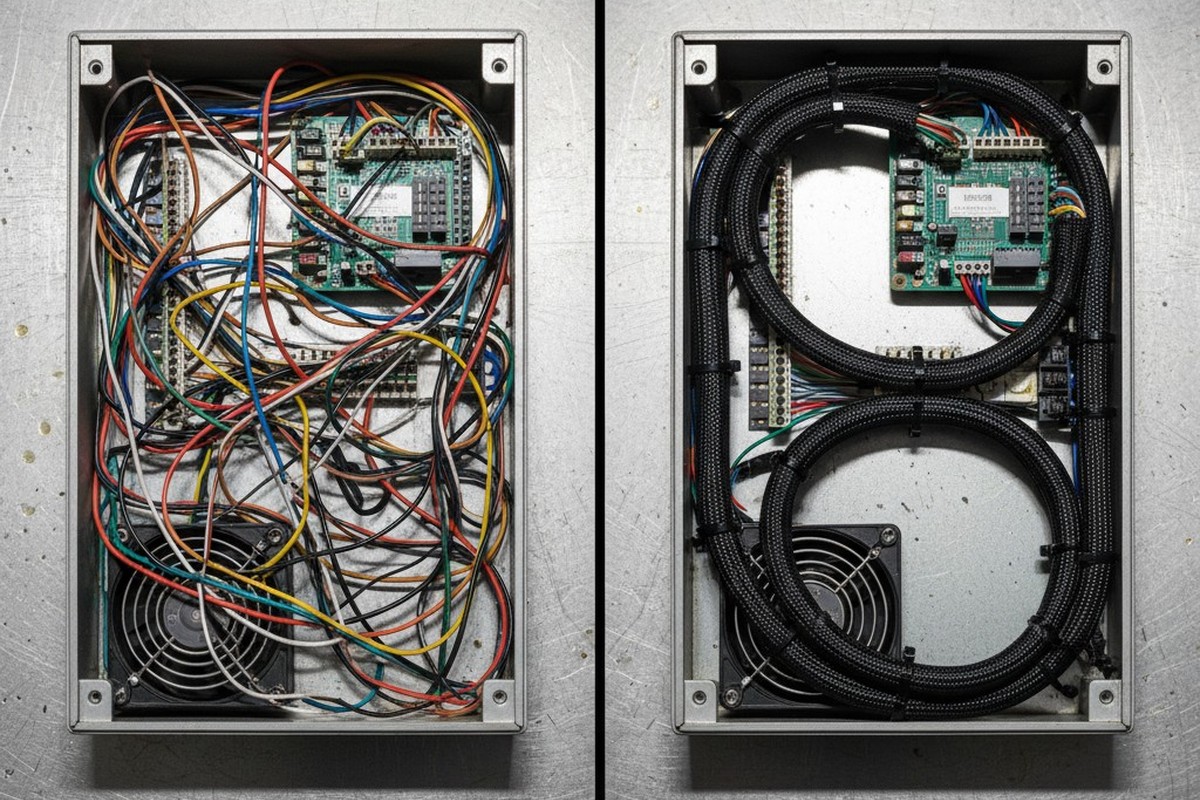

Box Build Cabling: Consistency in the Invisible Places

The quality of a box build is determined not by its polished exterior, but by its internal cabling. A clean, well-documented harness indicates reliability and prevents thermal and mechanical failures, while a messy ‘rats nest’ is a sign of future problems.