What is DFSM

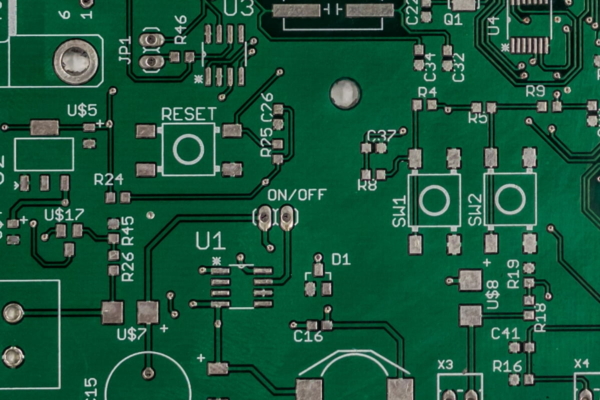

DFSM, or Dry Film Solder Mask, is a permanent material that is used for circuit protection on printed circuit boards, including flexible, rigid-flex, and other rigid boards. DFSM is typically a water-based or solvent-based material that is applied to the outer layer of the PCB.

The primary purpose of DFSM is to provide protection against oxidation, ensuring the longevity and integrity of the PCB. It also prevents solder bridges from forming between closely spaced solder pads, which helps to maintain proper electrical connections and prevent short circuits. Additionally, DFSM offers electrical insulation, allowing higher voltage traces to be placed closer to one another on the PCB.

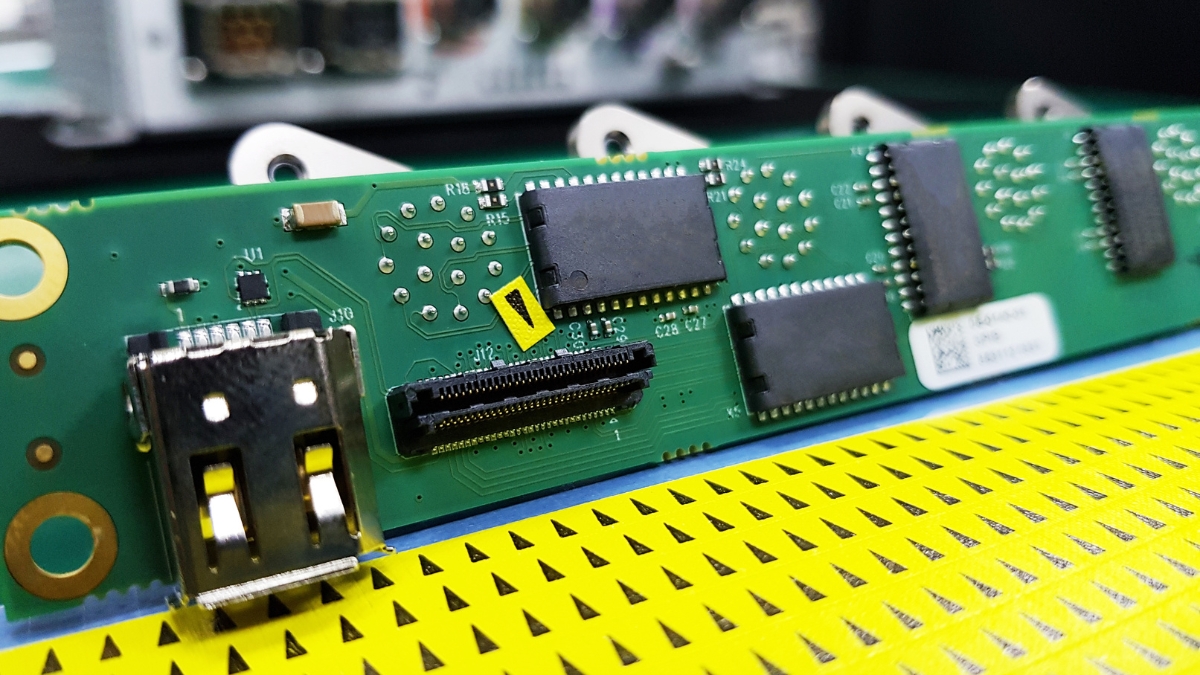

The application of DFSM involves a series of processing steps. It starts with surface preparation, ensuring the optimal adhesion of the dry film mask. Then, hot roll lamination is performed using a laminator machine, which applies heat and pressure to achieve a uniform distribution of the mask without any air inclusion. After lamination, the exposed areas of the mask are developed using an alkaline solution, followed by rinsing and drying.

To achieve optimal performance properties, DFSM undergoes a final cure process. This involves high-intensity UV exposure followed by thermal curing. The final cure ensures that the DFSM exhibits the desired physical, chemical, electrical, and environmental properties required for its application.