What is Laminate Thickness

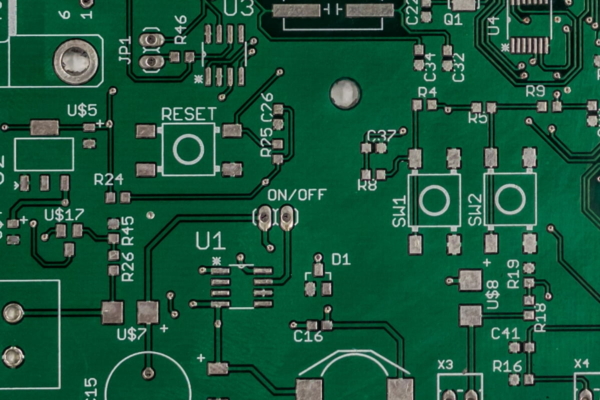

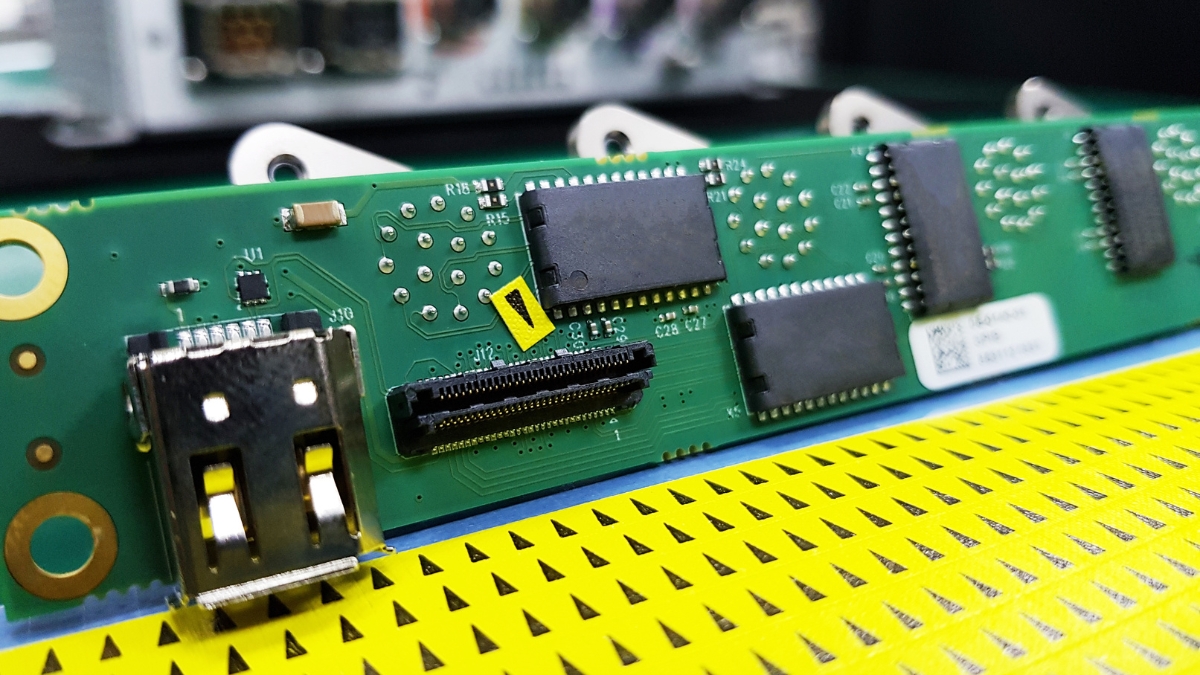

Laminate thickness is the measurement of the non-copper layers in a PCB stack-up. It specifically represents the actual thickness of the laminate material used in the construction of the PCB, excluding elements such as plating, finishes, soldermask, and silkscreen. The laminate material, composed of layers of thermoset resin and either paper or cloth, plays a crucial role in providing structural integrity and bonding the copper layers together.

The laminate thickness is a critical dimension to consider in PCB manufacturing, as it directly affects the overall thickness and various properties of the board. It is typically specified in mils or millimeters and can vary based on the specific requirements of the PCB design and intended application. The choice of laminate thickness involves trade-offs between factors such as mechanical strength, flexibility, rigidity, thermal conductivity, and electrical performance.

Manufacturers often guarantee a tolerance, typically around 10%, from the calculated thickness due to potential variations in the actual laminate thickness. Therefore, it is important to consider worst-case tolerances and work closely with the manufacturer when a rigid thickness requirement is necessary. Overall, laminate thickness is a key parameter in PCB fabrication, influencing the board’s structural integrity, thermal management, and electrical performance.