Blog

-

ECO In-Flight Control: How to Swap Revisions Without Scrapping WIP (and Without Lying)

ECO in-flight control keeps revision identity intact from release to shipment by anchoring changes to an effective operation, enforcing station-level document selection, and making quarantine non-borrowable. It replaces hope and training-only fixes with auditable gates, deviations, and fast traceability.

-

Consigned Kit Receiving That Actually Stops Wrong MPNs Before the Line Loads

Consigned kits can look correct while hiding wrong MPNs, polarity issues, or missing MSL evidence that only surfaces after the line is loaded. This guide lays out a two-cue receiving gate and an escalation ladder that stops ambiguity before it becomes scrap, rework, and line-down events.

-

Functional Testing Without Stable Firmware: Stop Calling It “Functional,” Start Measuring What Can’t Lie

When firmware is unstable, a green “functional” stamp can hide real defects. This piece reframes early testing around deterministic measurements—rails, clocks, resets, fixture proof, and fault-model coverage—so pass rates reflect reality, not optimism.

-

The Hidden Moisture Trap: Managing Borderline MSL Components

Moisture can hide in a sealed Moisture Barrier Bag and turn into steam during reflow, causing internal delamination that is not visible from the outside. The Humidity Indicator Card is the only reliable witness; ignore lavender or borderline readings and you risk field failures, while careful low-temperature baking and disciplined floor life management protect solderability.

-

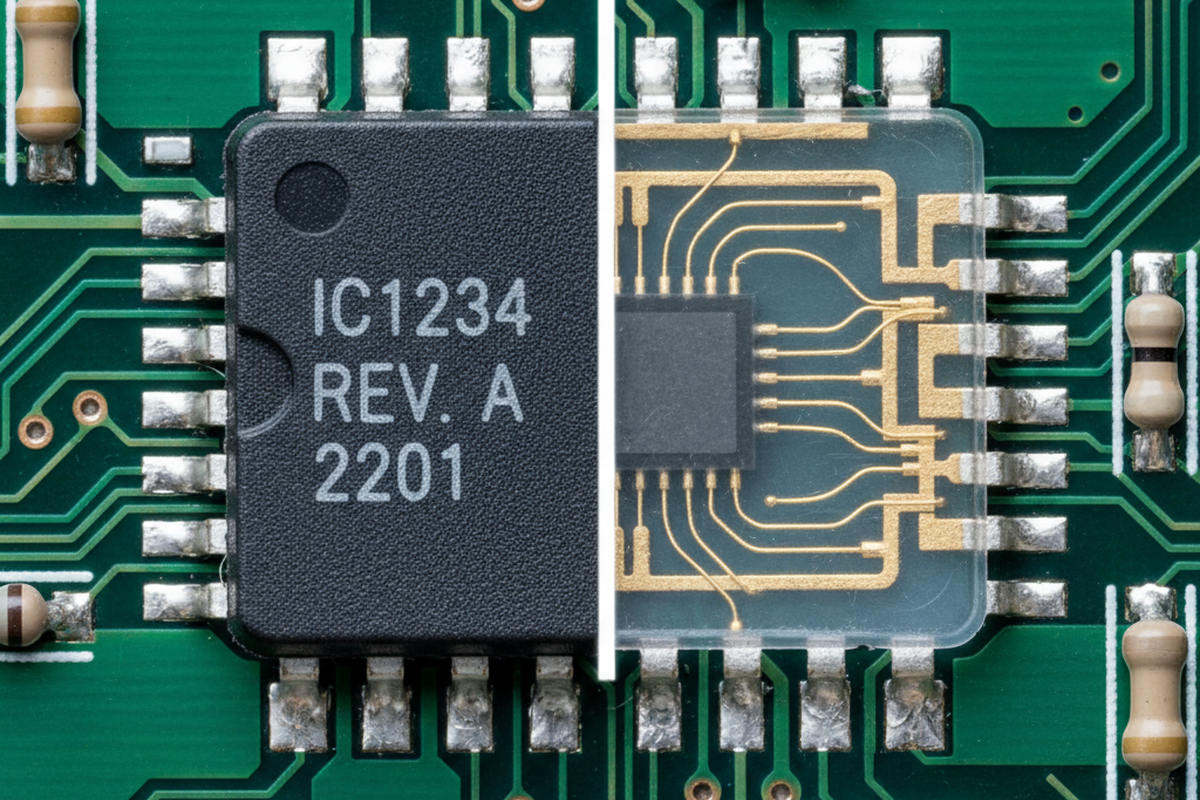

The Myth of the “Drop-In” Replacement: A Guide to Sourcing in the Allocation Era

Procurement is an engineering discipline that guards performance and availability in todays allocation era. This guide explains why exact part matches fail under DC bias, how parametric rigor and authorized provenance protect boards, and why designing for availability is the only path to reliable electronics.

-

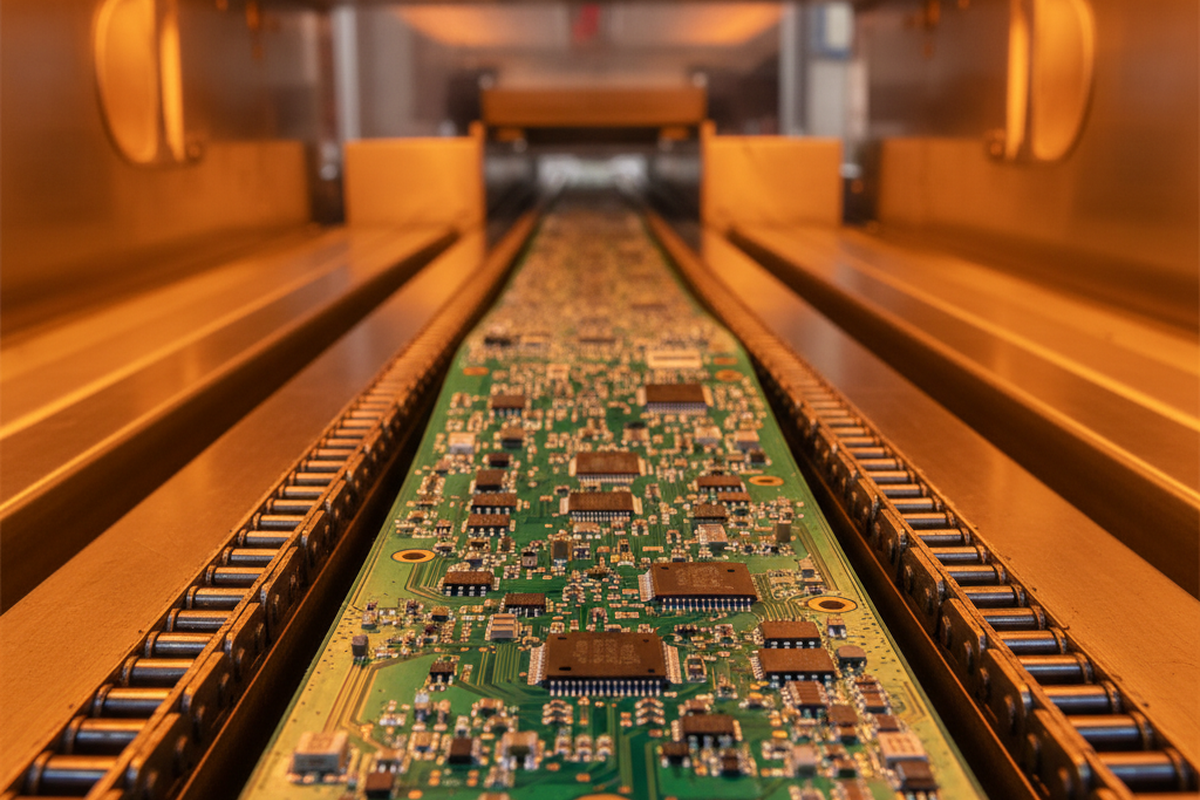

The Physics of the “Banana Board”: Why Long PCBs Warp and How to Fix It

Long PCBs bow and even fail mid-process as copper and FR4 expand at different rates and gravity sags the center. The remedy is mechanical support, such as center board supports or rigid pallets, to keep the board flat through the heat cycle.