Blog

-

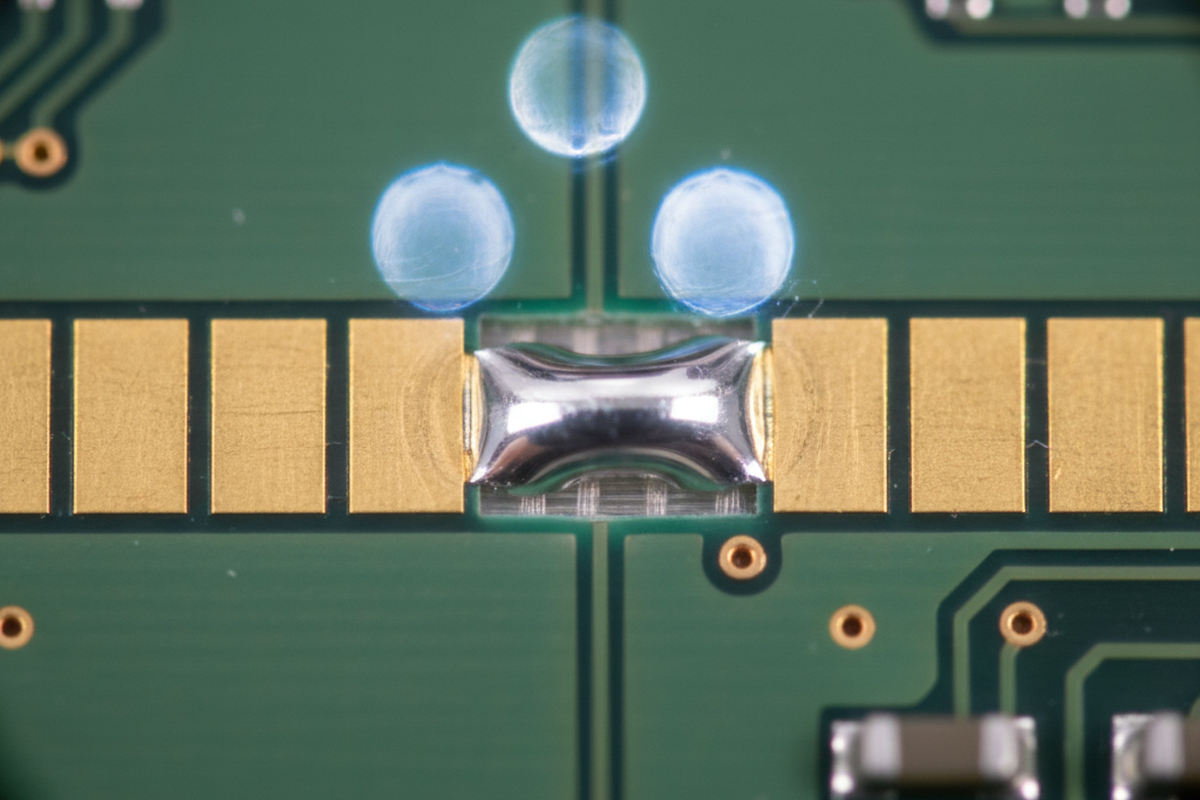

Solder Mask Expansion: The Invisible Yield Killer

At Bester we treat solder mask as a precision dam, not paint. This deep dive explains how default mask expansions can cause bridges on fine pitch pads, why fab margins cost reliability, and how LDI and careful web control protect yields.

-

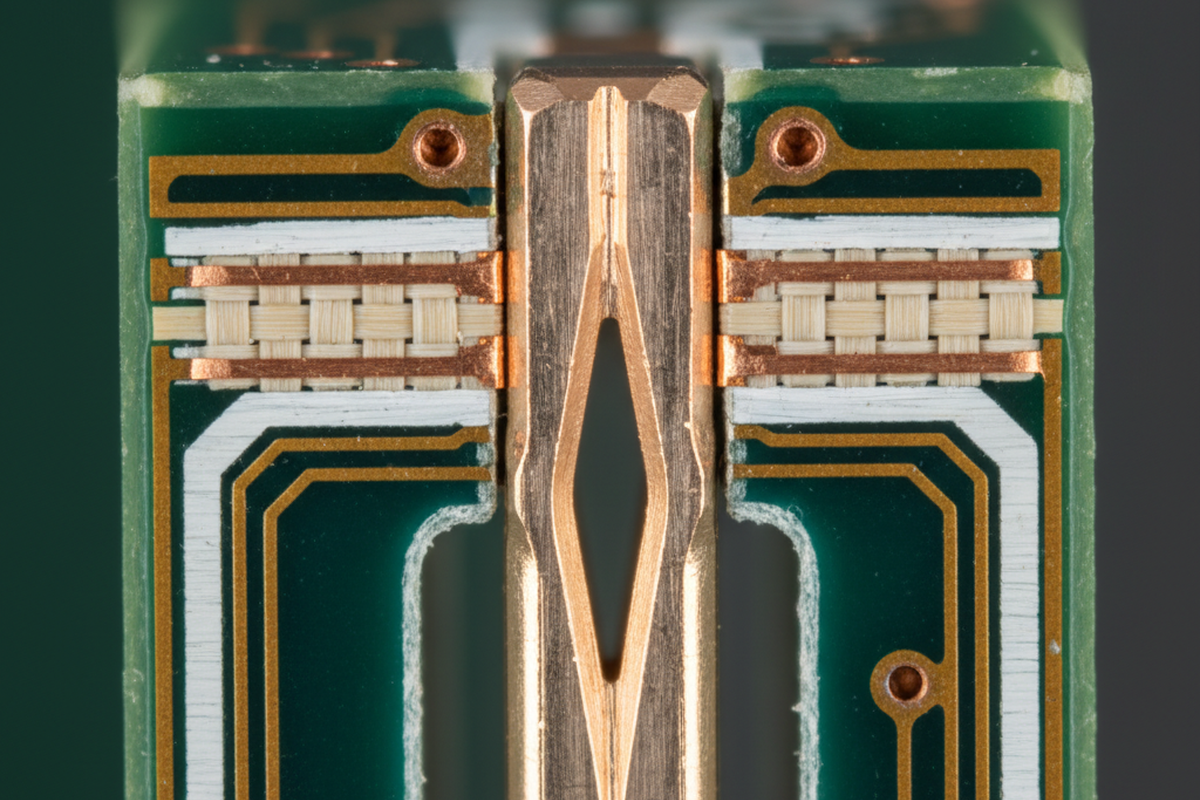

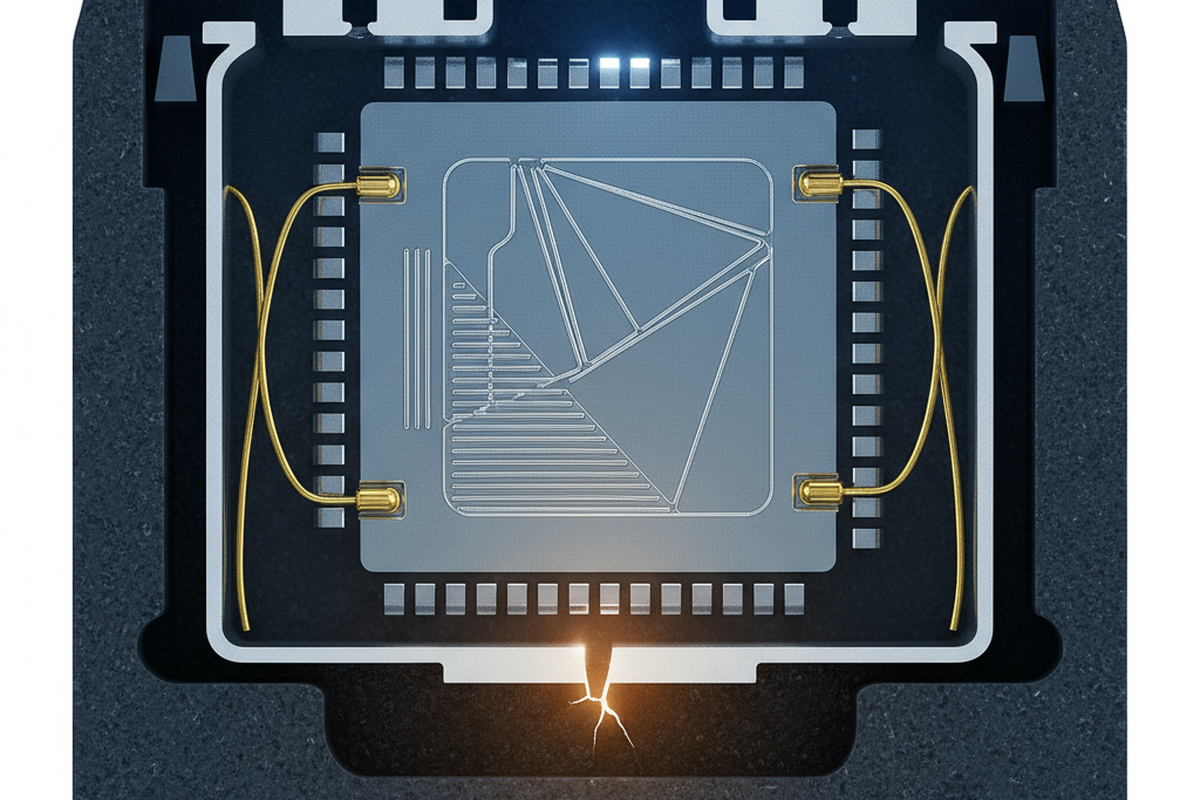

The Hidden Physics of Castellated Module Failures

Bester explains castellated module failures stem from CTE mismatch and brittle solder joints. Relying on datasheet footprints invites fatigue; the fix is toe extension, stencil overprint, and mindful edge placement to survive real-world environments.

-

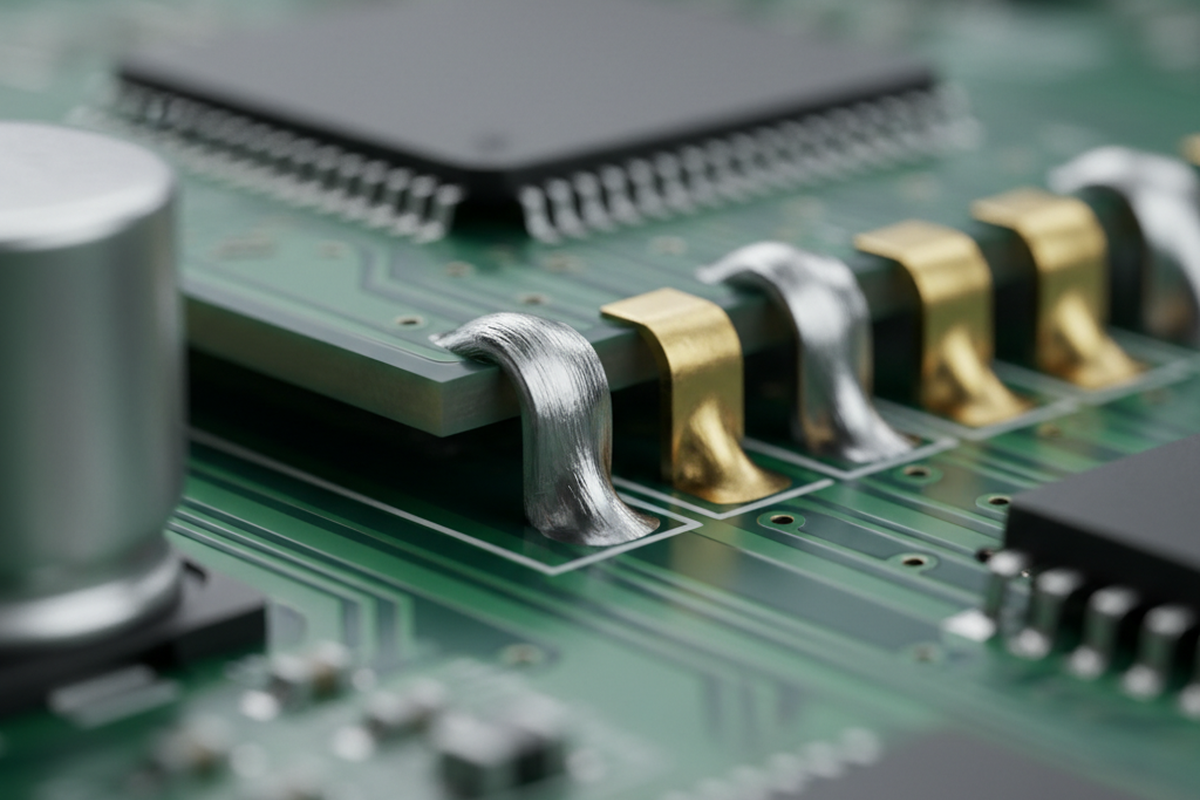

The Physics of the Brick: Selective Solder Tuning for High-Mass Joints

Shiny joints on heavy copper busbars can hide internal defects. This article shows why preheat soak and longer dwell are essential for reliable high-mass soldering, how inerting and flux choices protect the joint, and why cross-section checks confirm true hole fill.

-

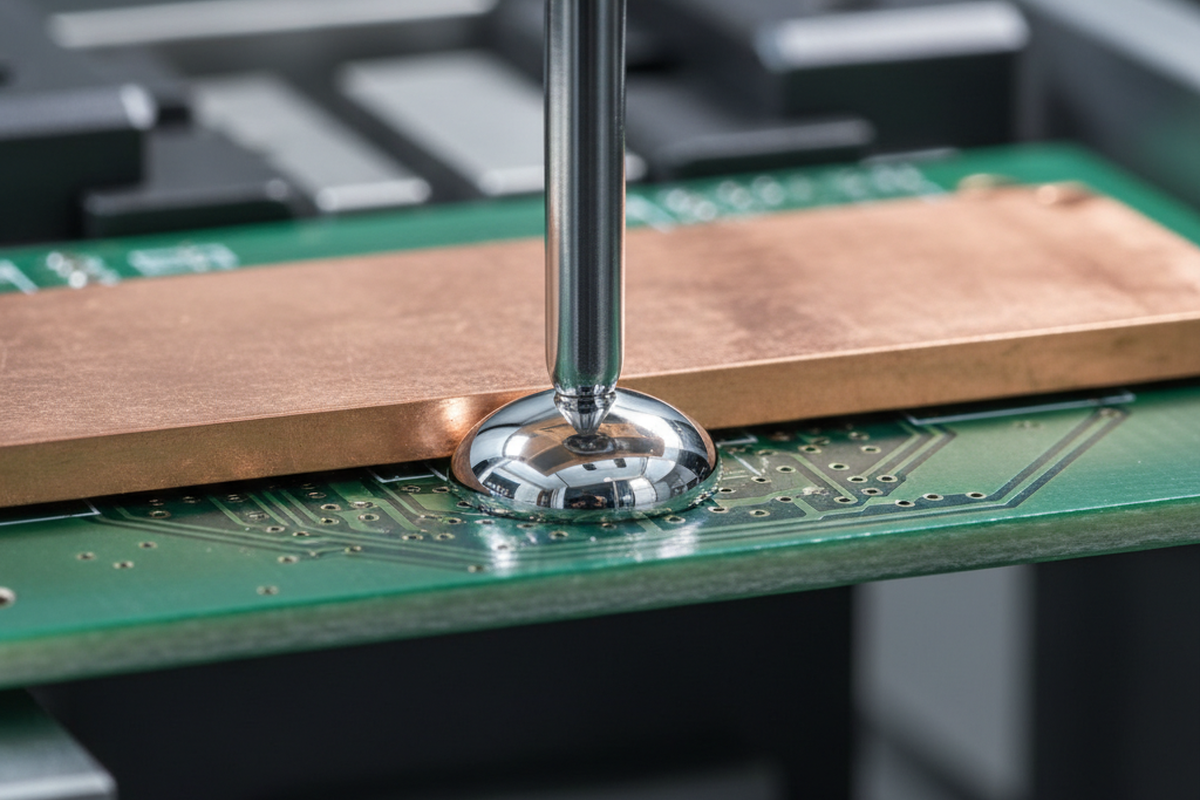

The “Ghost” Failure: Why Press-Fit Connectors Walk Out After They Leave the Factory

The ghost failure on press-fit connectors shows up after a flawless factory run: field returns reveal pins loosening due to thermal cycling, humidity, and harsh handling. It’s the pin, the hole, and the board that betray you long after turnup.

-

The Invisible Killer: Why “Passing” Boards Fail in the Field

Visually perfect boards can still fail in the field due to invisible ionic contamination trapped under components, causing leakage and parasitic power loss. Relying on bulk ROSE tests masks local hotspots, so the industry must adopt localized forensics and targeted cleaning to prevent recalls.

-

The Silent Killer: Why MEMS Pass Reflow but Fail the Field

MEMS sensors may pass factory ICT tests but drift weeks later due to hidden moisture delamination. This piece explains the failure mechanism inside MEMS packages, why bake cycles fail, and the strict pre-oven discipline needed to prevent costly field recalls.