Blog

-

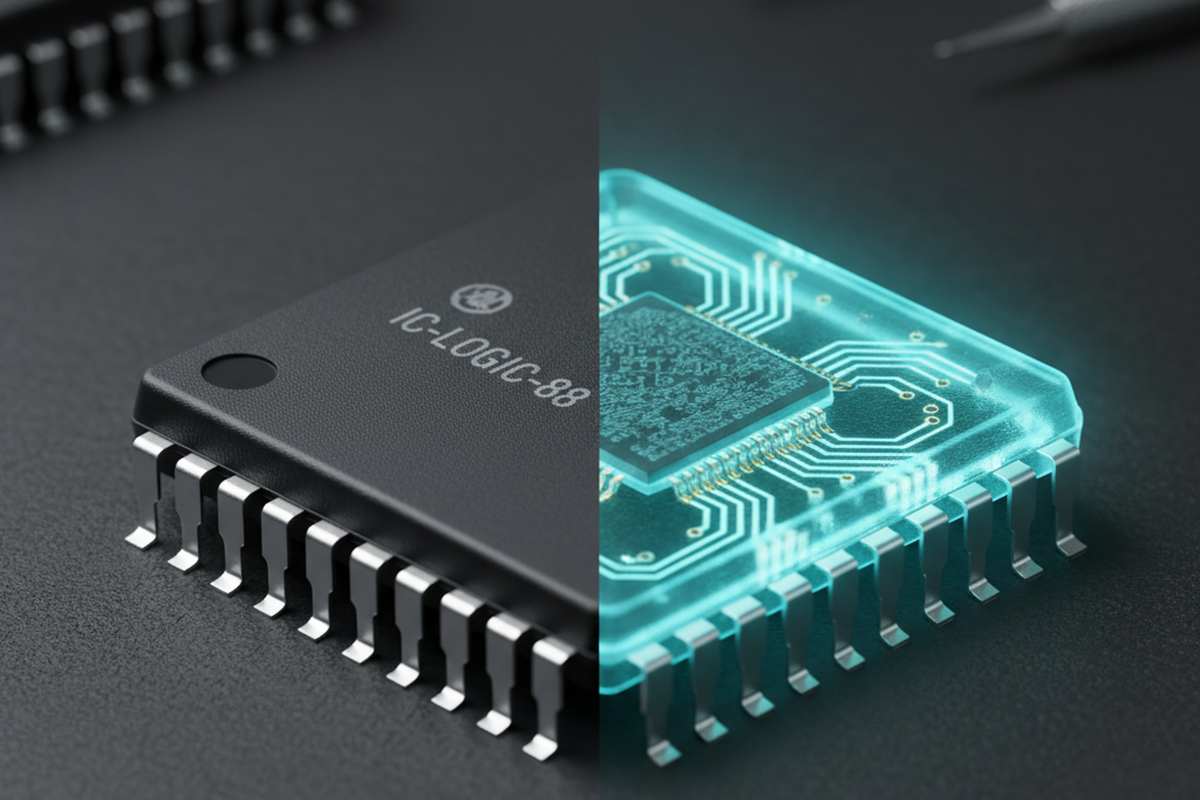

Counterfeit Component Mitigation: A Field Guide to Incoming Inspection

Counterfeit components threaten safety and reliability, especially in medical and avionics. This field guide to incoming inspection outlines forensic checks from paperwork autopsy to X-ray verification, solvent tests, and real-world tossouts to prevent costly failures.

-

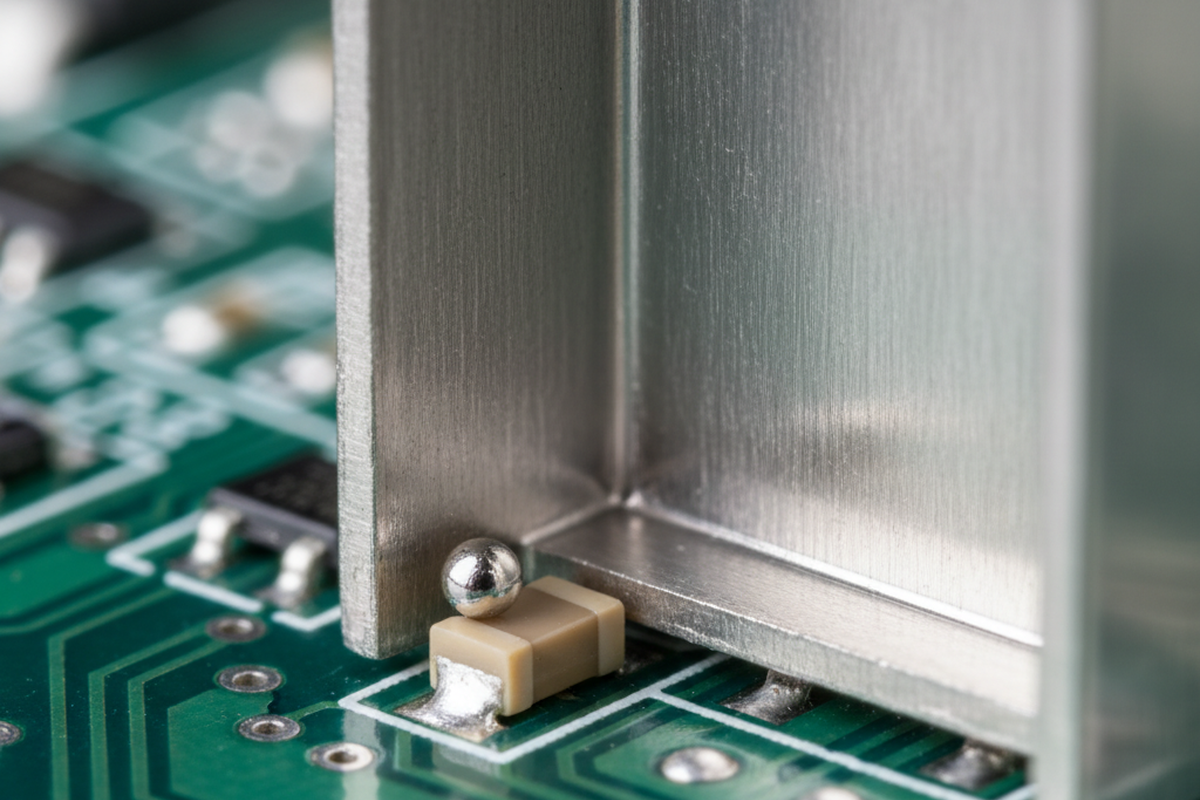

The Hidden Rattle: Solving Under-Can Solder Beading in RF Modules

Solder beads under RF shield walls can quietly derail a module after field cycles. This article shows how aperture design, reduced paste, and mindful layout stop bead formation, preventing leaks, shorts, and reliability failures from vibration and thermal cycling.

-

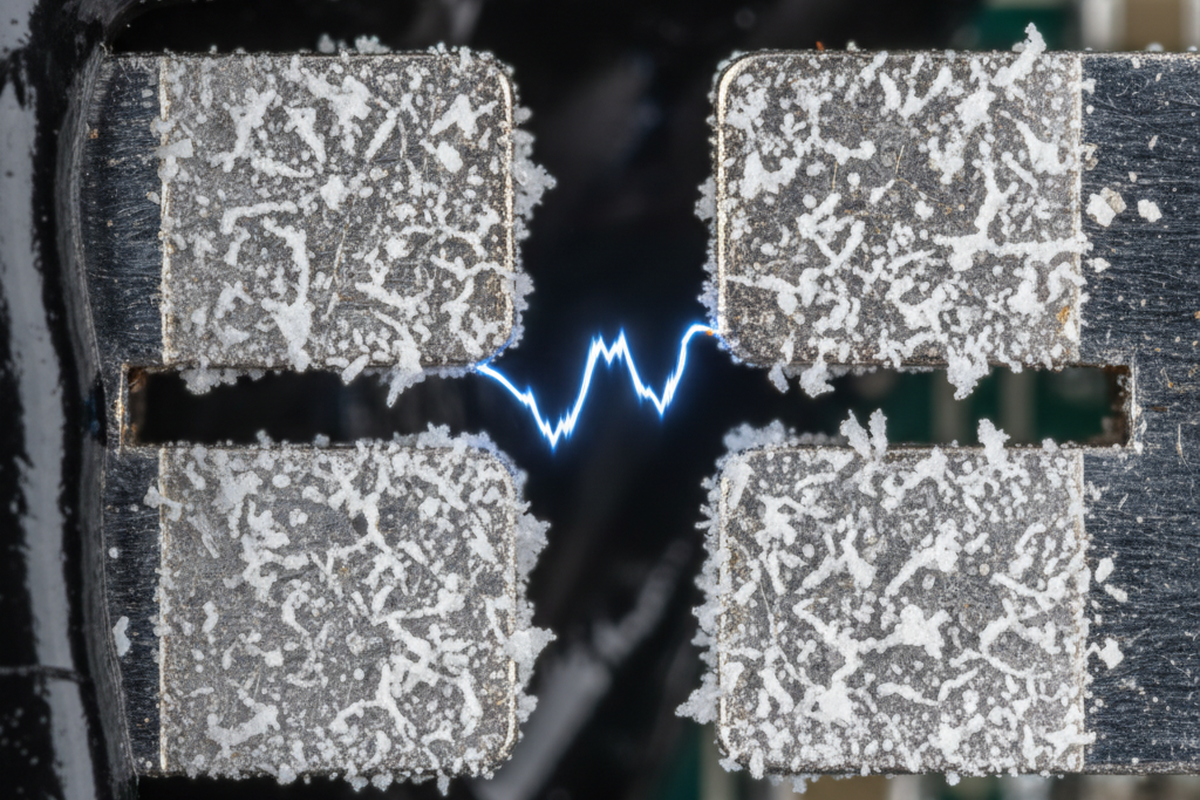

The Glass Engine: Why Silicone Kills Sealed Electronics

sealed electronics fail from silicone outgassing inside the enclosure, laying a nanoscopic glass layer on contacts and killing relay function. the article explains why electronic grade silicone is not a cure and points to urethane or epoxy alternatives and strict outgassing tests like astm e595 as the right spec.

-

The $40,000 Paperweight: Why “Perfect” Test Coverage Kills Low-Volume Hardware

Low-volume hardware production demands flexible, cost-efficient test strategies over “perfect” coverage. Instead of pricey fixed fixtures, using firmware-based functional tests and simple human-centric setups ensures reliable manufacturing without bankrupting your run.

-

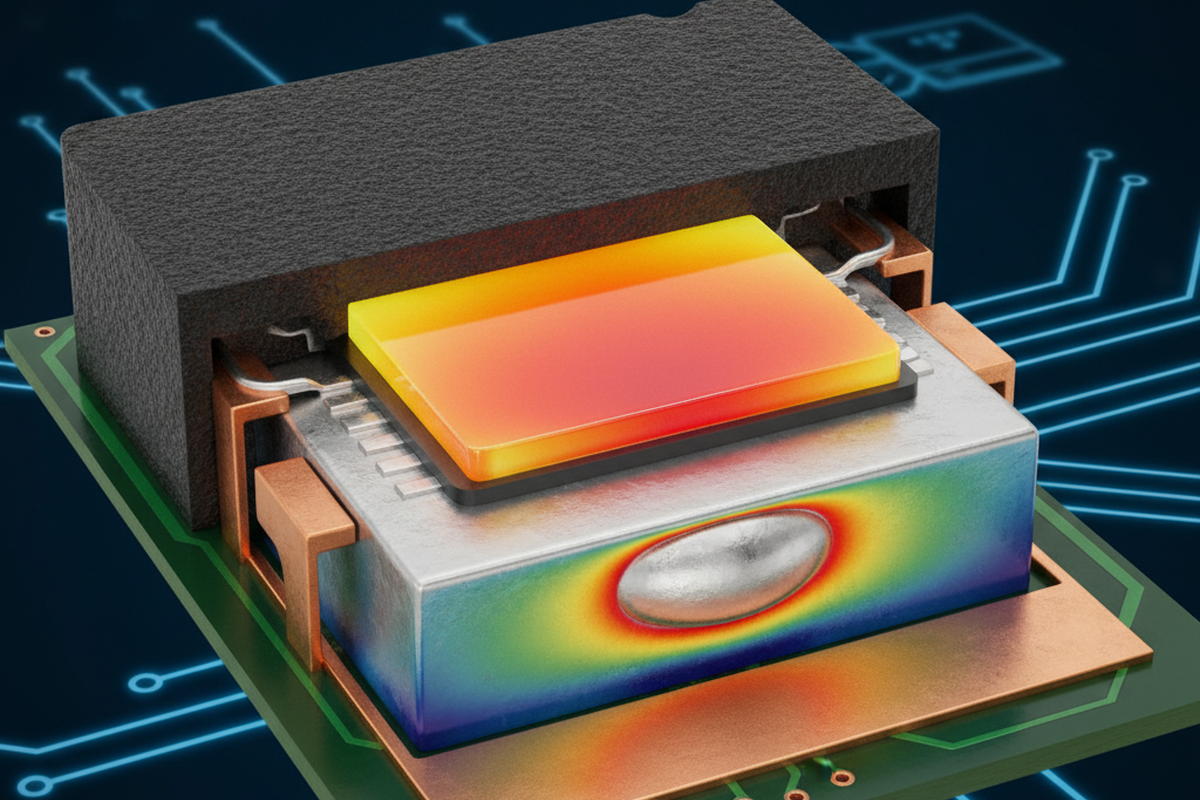

The Thermal Reality of Voiding: Why IPC Pass/Fail Isn’t Enough for Power

IPC pass fail masks real risk when voids sit under the die. Bester argues that thermal path integrity and 3D inspection beat total void percentages, guiding smarter grading to prevent failures and recalls in high power electronics.

-

The Box Build Reality Check: When CAD Lies and Cables Fail

On the factory floor, cables designed in CAD can snap under real world stress. This reality check explains why deterministic routing, service loops, and solid strain relief prevent field failures in box builds.