Blog

-

The Invisible Film: Why “Electrically Clean” is Optically Fatal

Sealed optical modules can pass electrical tests yet fog the lens with volatile residues that outgas inside the enclosure. True image quality demands true optical cleanliness: localized sensor-area testing and IC-level checks rather than blanket ROSE or blanket washes.

-

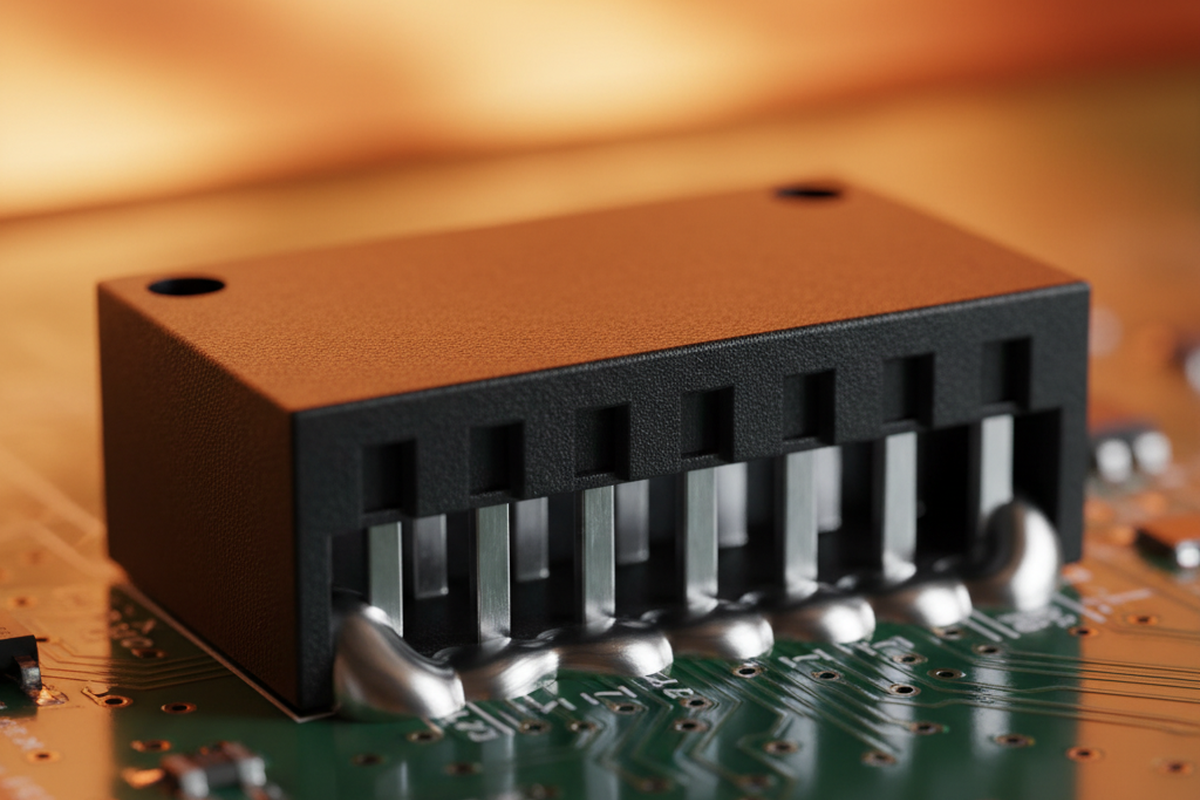

The “260°C” Myth: Why High-Temp Connectors Fail in Reflow

260c for 10 seconds is a dangerous simplification. Reflow stresses, CTE mismatch, and moisture can warp connectors and lift pins even when solder seems fine; choose stable materials like LCP and add mechanical fixes to survive real manufacturing.

-

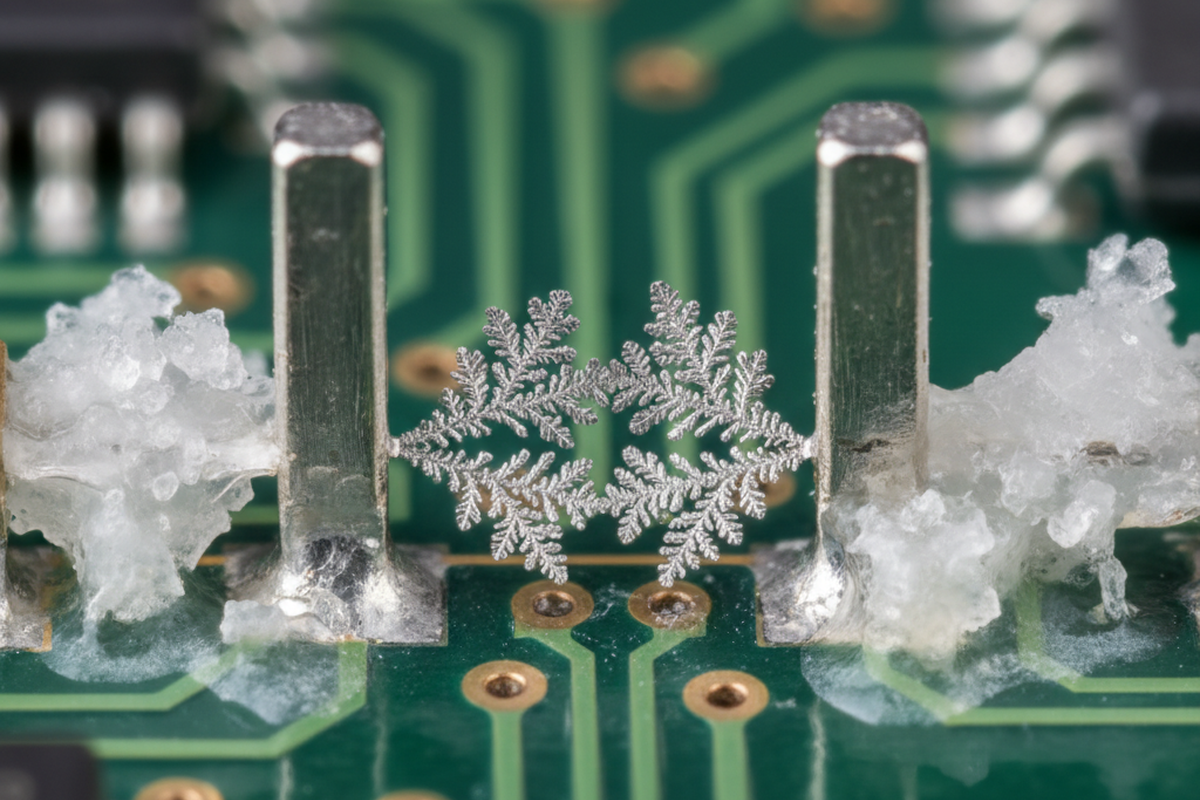

The Invisible Current: Why “No-Clean” Flux is Killing Your Battery Life

Ultra-low power devices rarely fail from the battery; they fail from the board, where hidden flux residue becomes conductive in humidity and creates a parasitic drain. A proper inline wash and ion chromatography proof can reclaim years of battery life.

-

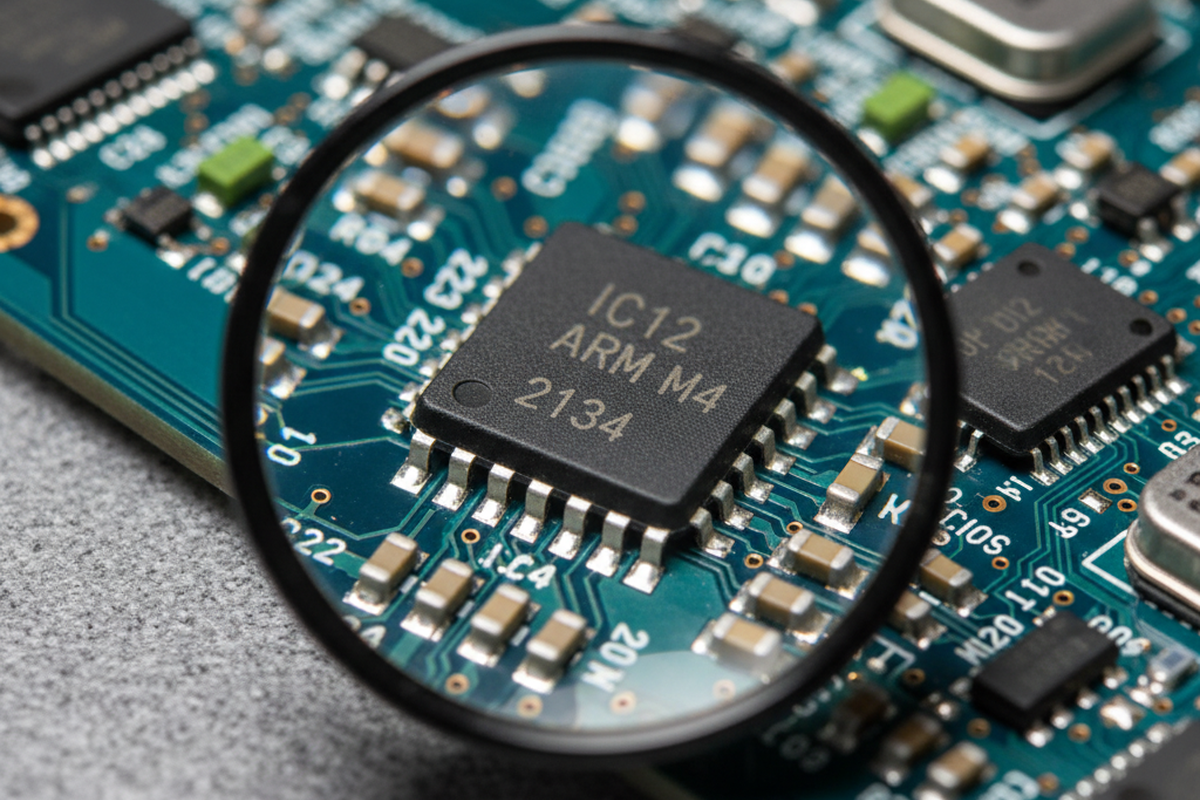

The “Golden Unit” is a Myth: Preventing PCBA Revision Drift

Revision drift is the silent enemy of hardware, Bester notes. When production documentation loosens, the AVL, BOM, and assembly drawings drift and field failures follow.

-

The Hidden Cost of “Forever” Glue: A Field Guide to Underfill Strategy

A field guide to underfill choices reveals how capillary flow, Tg, and corner bonding influence repairability and cost. The wrong material can turn repairs into scrap, while the right strategy preserves yield and lowers total ownership.

-

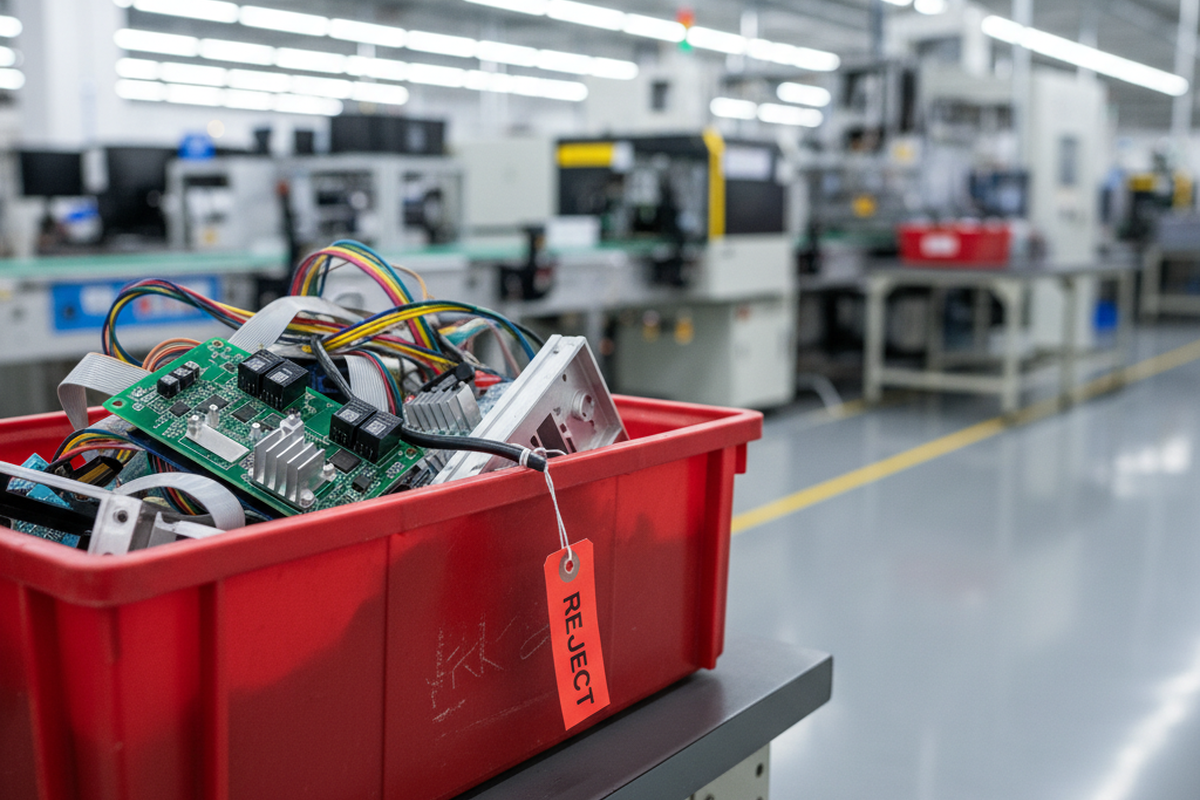

The Entropy of Invoices: Why Revision Collisions Kill Yield

Revision collisions derail manufacturing lines when ECOs arrive out of sync, producing the wrong units and wasted time. The article traces how linked revisions, waivers, and firmware vs hardware changes create soft yield loss and argues for a hard, clean break to protect margins.