Blog

-

The Thermal Lie: Why Your Void Criteria Are Failing Your Hardware

Voiding percentages aren’t a reliable gauge of a part’s reliability. Heat flow and void location trump total voids, and true reliability comes from measuring dynamic thermal response (Zth) and junction temperature, not chasing a perfect X-ray image.

-

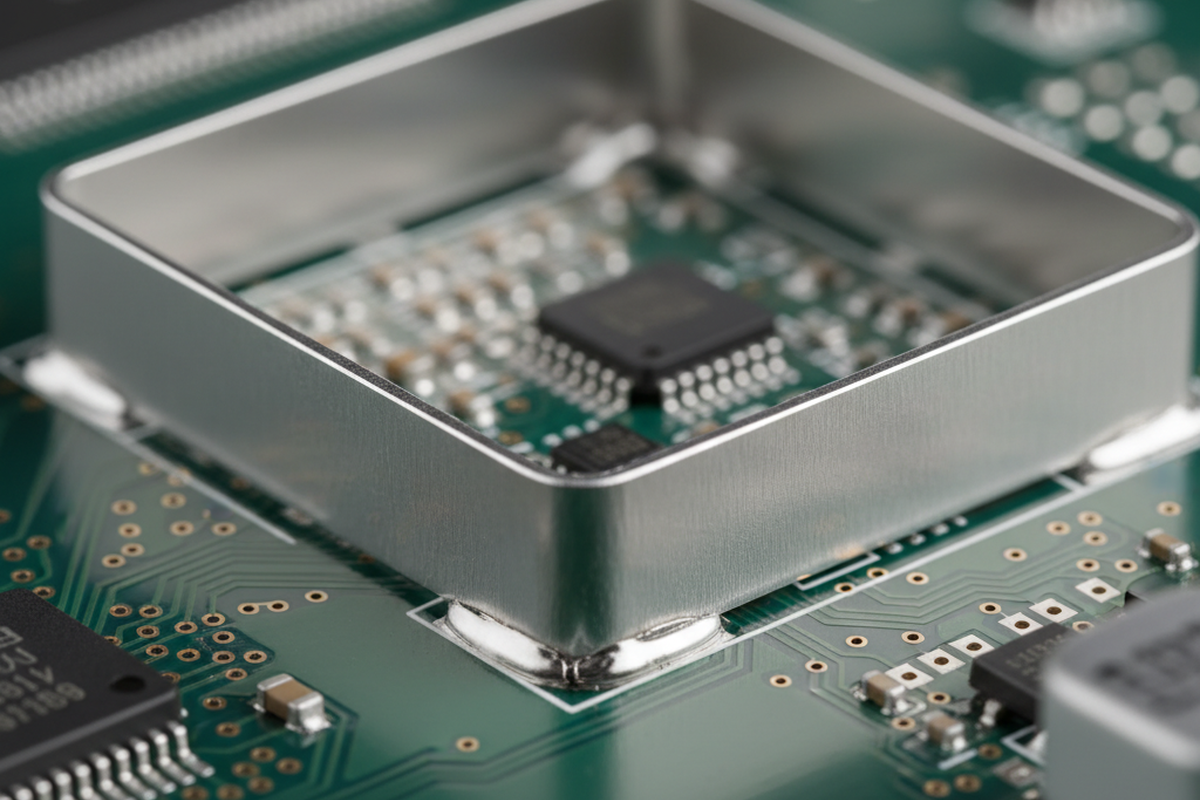

The Physics of the Shield: Avoiding the “Bead Trap” in RF Assembly

RF shield bead be careful: the shield can on a mixed-signal board is a silent yield killer. This guide shows how to prevent it with dash patterns, reduced paste, and two‑piece shields or clips for easy inspection and reliable reflow.

-

The Thermodynamics of Failure: Why Potting Cooks Your Boards

Potting electronics isn’t a simple drying process; it’s a violent exothermic reaction. The internal heat generated by curing epoxy can easily exceed 180°C, cooking sensitive components and causing failures from thermal shock and CTE mismatch long before the device reaches the field.

-

X-Ray Void Analysis: Criteria That Match the IPC Class

Solder voids in electronics often look like critical defects, but they are a natural part of the manufacturing process. This article demystifies X-ray void analysis, explaining the IPC-A-610 standards and why the location of a void is more important than its size for ensuring long-term product reliability.

-

The Mechanics of the Clean Edge: A Guide to Reliable Castellations

Discover the mechanics behind creating reliable castellated edges on your PCBs. This guide explains how to prevent common failures like copper tearing and solder bridging by focusing on correct geometry, anchor vias, surface finish, and clear fabrication notes.

-

The Invisible Abrasion: Why ENIG Fails on Edge Connectors

Standard ENIG gold plating is often too soft for edge connectors, leading to rapid abrasion, connection failure, and costly field recalls. Understanding the difference between soft ENIG and durable Hard Gold is critical for designing reliable hardware.