Blog

-

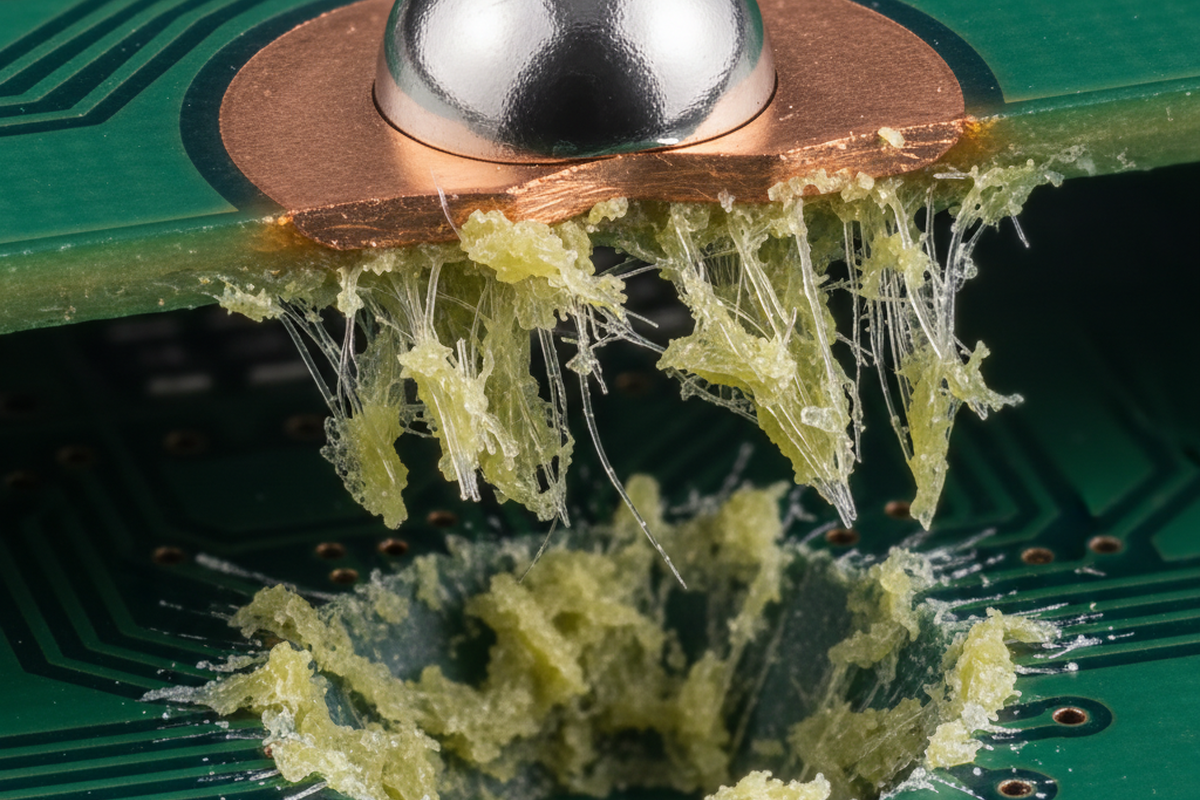

Staking Versus Epoxy: Ruggedization Choices That Decide Long-Term Repairability

Rugged boards should survive harsh environments, but thick epoxy potting often backfires by trapping heat and stressing solder joints. The article argues for surgical staking with compliant materials to protect components while preserving repairability.

-

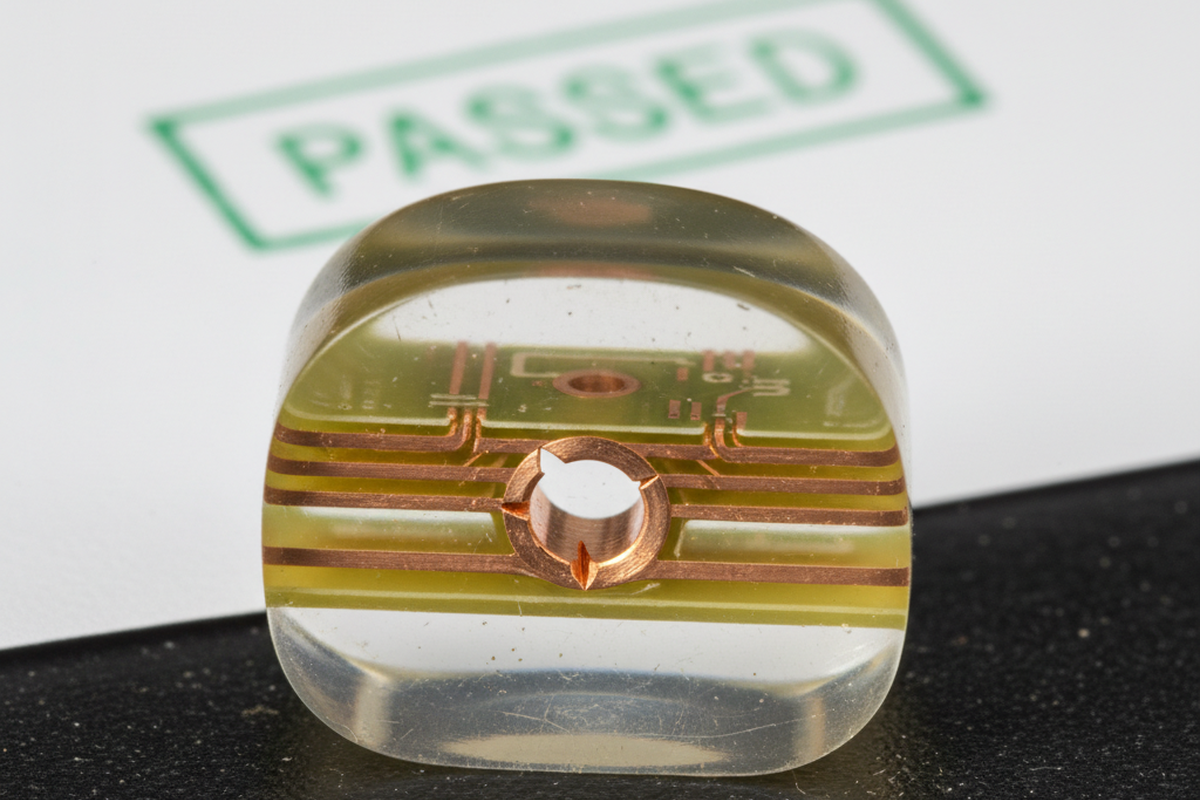

The Golden Coupon Paradox: Why Passing Reports Hide Failing Boards

The Golden Coupon paradox shows a passing CoC can hide a failing board, because coupons that mirror only easy geometry miss the hard truth and invite field recalls.

-

The Geometry of Failure: Why Castellated Modules Crack in the Field

Bester explains that castellated joint failures stem from geometry, not bad parts, and appear under vibration and thermal cycling. The guide shows how extending pads to form a strong heel fillet, trimming stencil apertures, and validating joints for lean production improves field reliability.

-

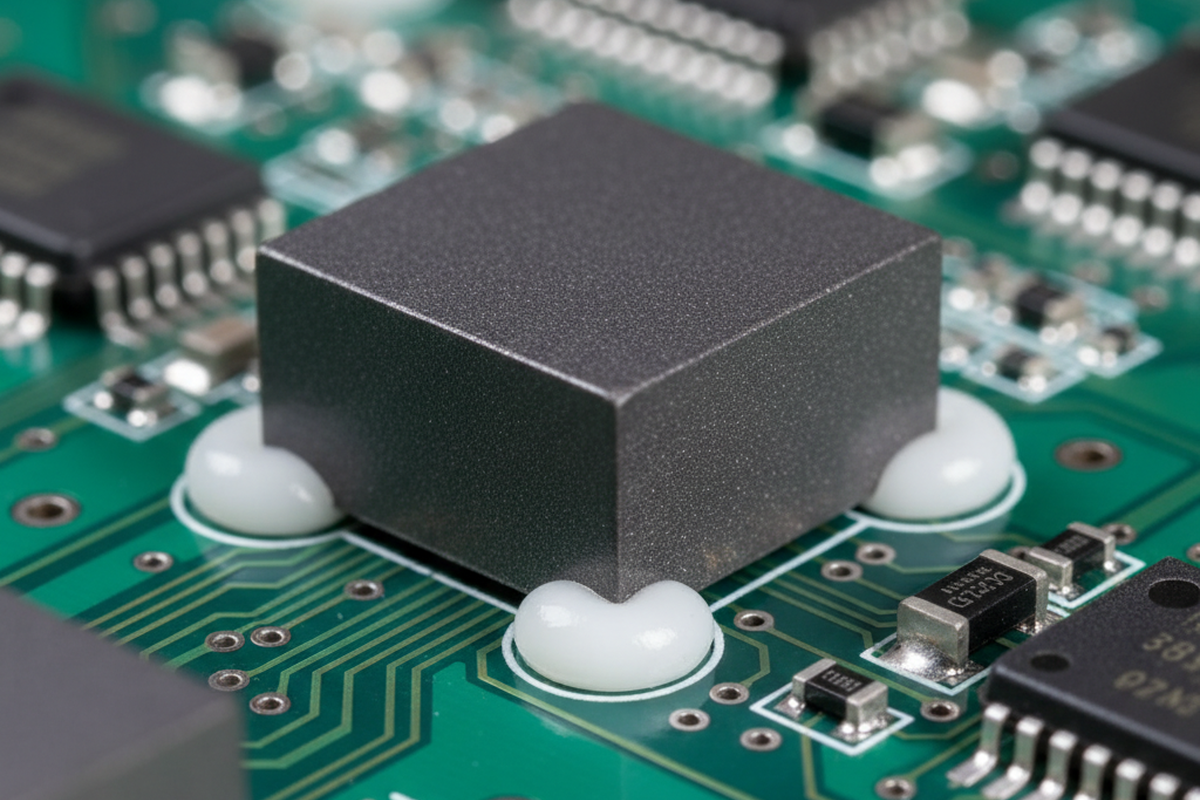

The High Cost of “Indestructible”: A Guide to Repairable Ruggedization

Ruggedizing industrial electronics by fully potting printed circuit boards can lead to expensive repairs or total replacement. Selective mechanical reinforcement like staking heavy components and corner bonding BGAs preserves serviceability, reducing lifecycle costs and improving repairability without sacrificing protection.

-

The Floor Drops Out: Why Your PCB Laminate is Failing Drop Tests (And Why It’s Not a Material Defect)

Bester explains why PCB laminates crater under drop tests, showing that pad cratering is a mechanical failure, not a resin defect. The article links mounting stiffness, teardrops, and solder choice to energy absorption and board resilience.

-

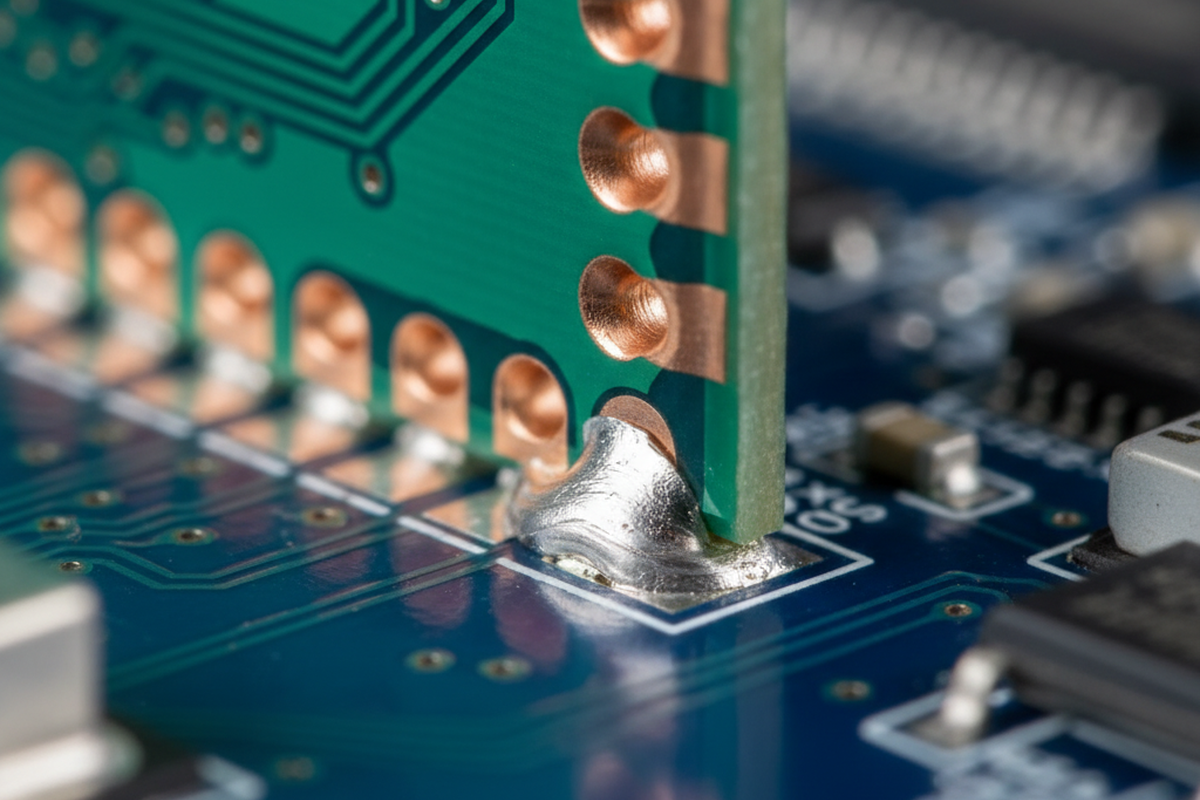

The Invisible Failure: When Selective Soldering Eats Its Own Connection

Cold, hidden failures in selective soldering threaten high-rel boards long after joints look perfect. This piece explains copper dissolution under a shiny fillet and why temperature, flow, and copper content drive a dangerous, unseen erosion.