Blog

-

Broker Buy Containment, in Practice: A Field Guide for PCBA Teams Who Can’t Afford Vibes

A practical field guide for PCBA teams buying through brokers: how to quarantine, tier risk, choose defensible sampling, and use trigger-based escalation so uncertainty shrinks before parts hit production.

-

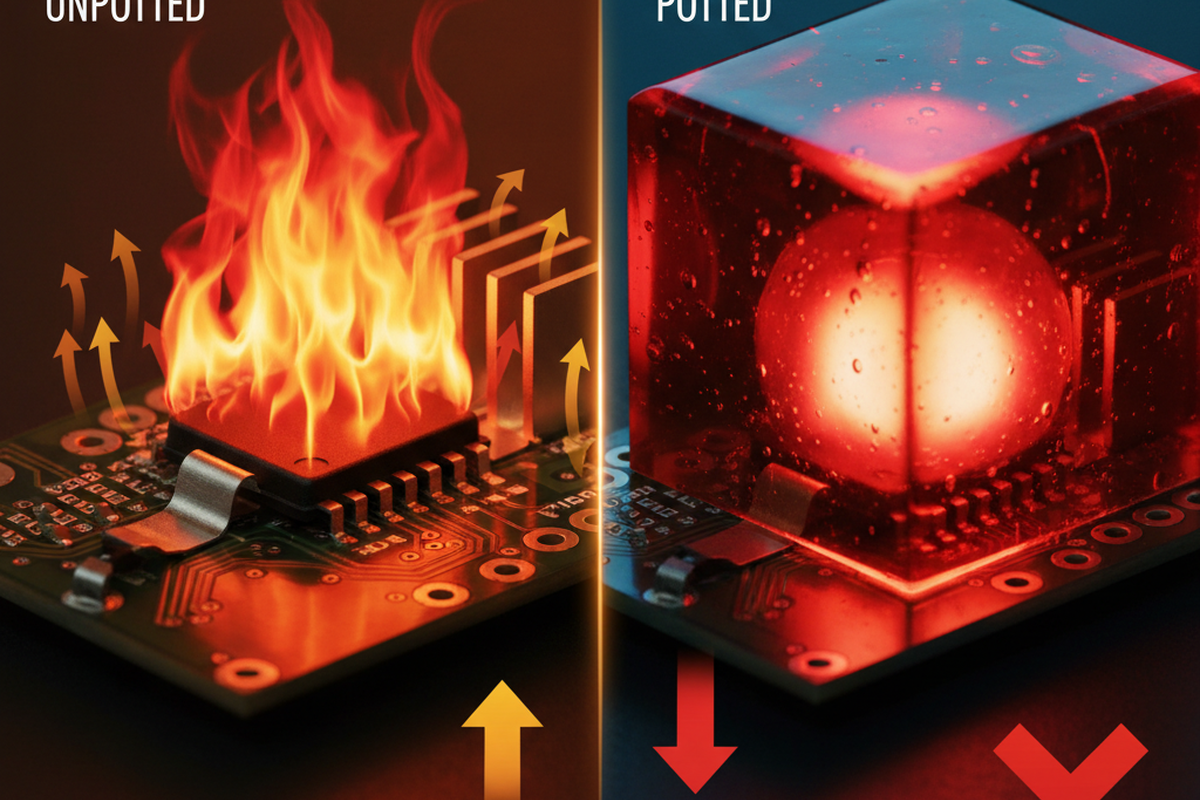

Staking and Potting Without the Heat Trap: A Field Guide for Hardening Assemblies

Potting and staking can harden electronics while quietly breaking thermal paths and serviceability. This field guide shows how to map load and heat paths, choose the least irreversible fix, and validate with a simple instrumented A/B MVQ.

-

RMA Failure Analysis That Actually Closes the Loop (Fast)

A staged RMA failure-analysis loop that drives fast decisions without overclaiming: disciplined intake, 48-hour triage, parallel containment, and corrective actions that land in controlled documents. Stop shipping uncertainty and start closing the loop with evidence that survives scrutiny.

-

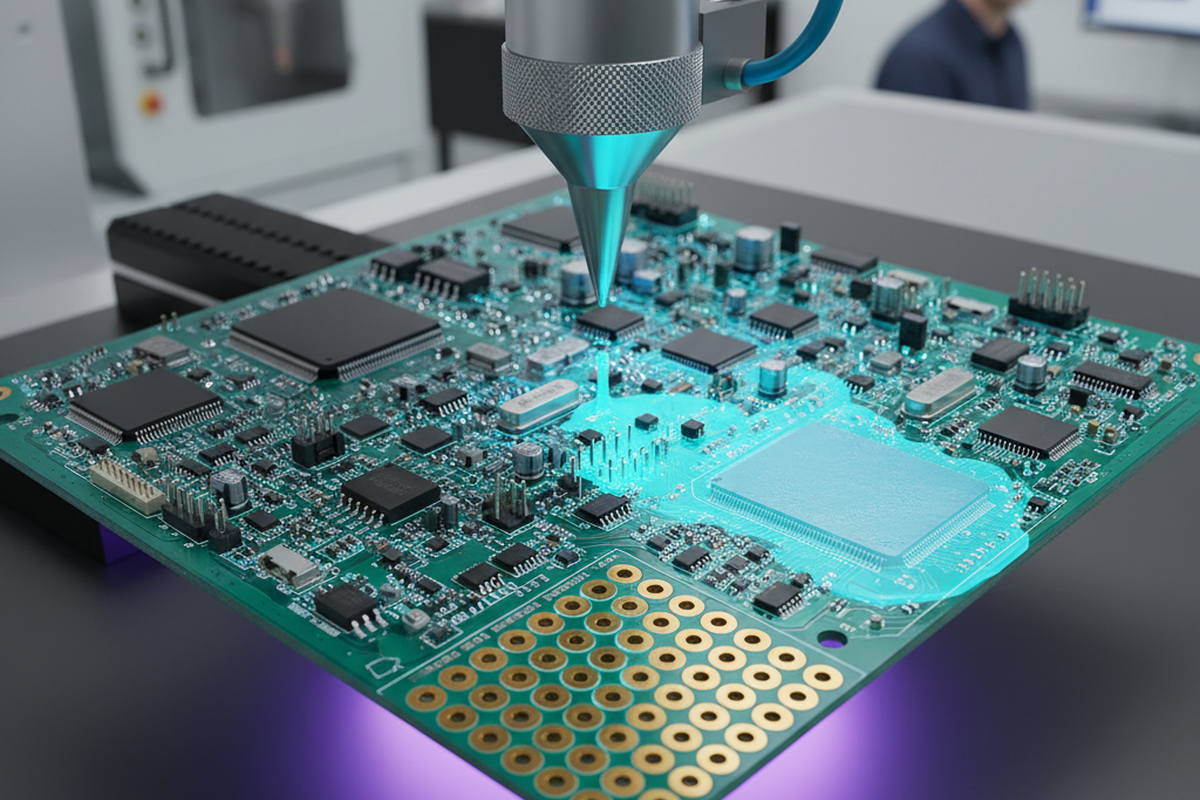

Selective Conformal Coating That Doesn’t Kill Test or Turn Rework Into Folklore

Selective conformal coating can boost reliability while quietly wrecking ICT, connector performance, RF behavior, and rework time. This article shows how keep-outs, controlled thickness, verification evidence, and a defined rework loop prevent costly false-fails and “mystery” intermittents.

-

Traceability That Doesn’t Steal Seconds: A Field Guide for SMT Teams Who Still Have to Ship

Recall-grade traceability is the ability to answer the containment question fast: which shipped serials used a specific supplier lot. This field guide shows how to capture defensible material links upstream, design for exceptions, and ship reports procurement and quality can trust without slowing the line.

-

Staged Builds Without Double-Handling Chaos: A Field Guide That Treats WIP Like a Process

Staged builds fail when work-in-progress becomes unknowable. This field guide shows how to run staging like a real process with defined WIP states, hold points, quarantine, thermal and MSL controls, and storage/kitting discipline—so “mostly done” never turns into untraceable rework.